KRICT Develops New Organic Thermoelectric Material... Maintains Performance Even After Over 3 Weeks of Exposure

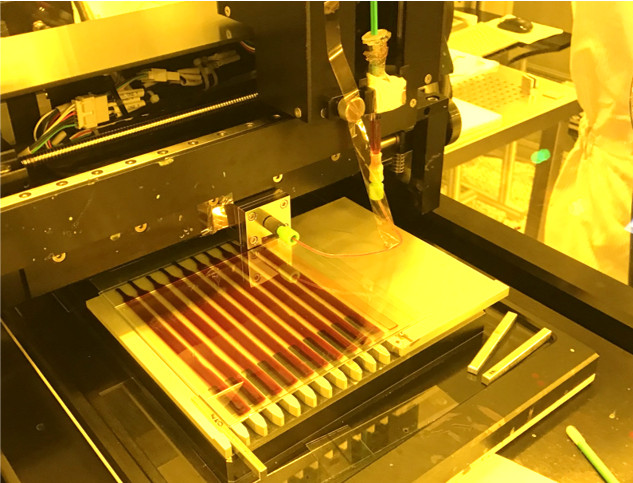

The process of fabricating thermoelectric devices using slot-die printing. Photo by Korea Research Institute of Chemical Technology.

The process of fabricating thermoelectric devices using slot-die printing. Photo by Korea Research Institute of Chemical Technology.

[Asia Economy Reporter Kim Bong-su] A lightweight, flexible, and inexpensive organic thermoelectric material that converts human body heat into electricity for use as energy in wearable devices, smart sensors, and the Internet of Things has been developed with long-lasting performance.

The Korea Research Institute of Chemical Technology announced on the 28th that it has developed a new organic thermoelectric material that is lightweight, flexible, and can be manufactured cheaply through printing processes while maintaining long-lasting performance.

Thermoelectric materials refer to materials that generate electricity when heat is applied or, conversely, generate heat or cooling when electricity is applied. Among organic thermoelectric materials, a representative polymer material called ‘polythiophene’ has been developed so far, but its thermoelectric performance drops by more than 80% after just one week, making commercialization difficult.

The research team improved this by developing a new polythiophene-based material that maintains thermoelectric performance even after being exposed to air for more than three weeks. This is the first development of polythiophene with long-lasting performance in air.

The team solved the performance degradation problem by applying a small amount of a gold chloride solution onto the polythiophene material. When polythiophene meets gold chloride, a chemical reaction occurs, producing gold chloride ions and gold nanoparticles, creating a unique polymer crystal structure. The gold chloride ions in this crystal structure enhance thermoelectric performance, and the gold nanoparticles help maintain the performance over time. The researchers found the optimal gold chloride concentration so that even a minimal application can sustain performance.

Notably, the material can be produced simply and inexpensively at room temperature using a printing process similar to newspaper printing. The polythiophene material is printed using a ‘slot-die printing’ method, where a wide blade applies the material like a brush, and then the gold chloride solution is applied on top.

Because the developed material is lightweight and flexible, it can be applied to wearable devices, smart sensors, and the Internet of Things in the future. When applied to vehicles or ships, it can convert waste heat into electricity for use. According to the global market research company IDTechEx, the global market size for thermoelectric devices grew from $274 million in 2018 to $746 million in 2022, with an average annual growth rate of about 54%.

Dr. Cho Sung-yoon said, “Although much research has been conducted on organic thermoelectric materials, there has been a limitation in that performance could not be stably maintained in air. This material has good electrical conductivity and long-lasting performance, so its application could expand to other electrode materials. We hope it can also be applied as a self-power source for wearable devices and sensors.”

The research results were published in the April issue of the international academic journal in the energy materials field, Nano Energy.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)