Korea Research Foundation, Research Team Led by Professor Im Won-bin of Hanyang University

Process Mechanism of Low-Temperature Synthesis Method

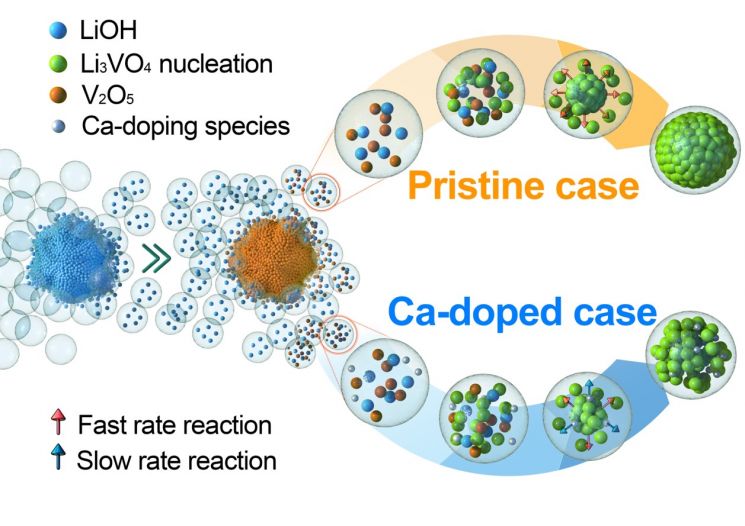

Process Mechanism of Low-Temperature Synthesis Method Reaction rate mechanism diagram according to the water solubility of raw materials. Water droplets generated from steam accelerate the synthesis and play a role in controlling the particle size of the synthesized material. In addition, substituting Ca (calcium) can control the particle growth rate and increase porosity, thereby expanding the surface area.

Figure description and provided by: Professor Im Wonbin, Hanyang University

[Asia Economy Reporter Kim Bong-su] A technology has been developed that can synthesize anode materials, a key component of batteries, at low temperatures using water vapor. This has attracted attention as it enables the production of anode materials in an eco-friendly and cost-effective manner.

The National Research Foundation of Korea announced on the 7th that Professor Lim Won-bin's research team at Hanyang University developed a technology to synthesize anode material using water vapor at low temperatures.

Anode materials, which release stored lithium ions to generate electricity, are one of the key components of batteries and determine the battery's capacity and lifespan. The conventional solid-state anode synthesis method requires high energy consumption due to high heat treatment temperatures and has difficulties controlling the shape of the material. Although liquid-phase synthesis methods favorable for shape control have been studied, they have the disadvantage of using large amounts of solvents (distilled water, organic solvents). The use of high-temperature conditions, toxic organic solvents, and expensive materials has caused environmental pollution and high energy consumption issues.

The research team designed an ultra-fine liquid-phase reaction that induces phase synthesis from the surface to the interior at a temperature of 80 degrees Celsius by spraying water vapor onto solid raw materials, synthesizing anode materials with uniform particle size and shape. This was to overcome environmental pollution caused by high-temperature synthesis processes, toxic organic solvents, and the high cost of materials. Instead of toxic solvents, the team enabled synthesis at low temperatures using a very small amount of water vapor. This new synthesis method is eco-friendly and economical as it allows material synthesis at low temperatures using a very small amount of water vapor instead of toxic solvents.

This low-temperature ultra-fine liquid-phase reaction method has also proven to improve surface control and electrochemical performance in lithium battery anode materials. It is expected to be widely applied as an eco-friendly synthesis method for various energy storage materials in the future.

The results of this study were published on the 25th of last month in the international academic journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.