DGIST Professor Lee Yong-min and Joint Research Team "Attention to Utilization in Next-Generation Secondary Battery Development"

[Asia Economy Reporter Kim Bong-su] A technology for manufacturing ultra-thin anodes with a lifespan more than 50 times longer than conventional battery anodes has been developed.

The joint research team of Professor Lee Yong-min and Professor Lee Hong-kyung from the Department of Energy Engineering at Daegu Gyeongbuk Institute of Science and Technology (DGIST), and Professor Yoo Myung-hyun from the Department of Chemical and Biological Engineering at Hanbat National University announced on the 31st that they have developed an ultra-thin lithium metal anode manufacturing technology by adding a stabilizing additive to lithium metal powder. This technology can extend the lifespan by more than 50 times compared to existing anodes, drawing attention for its potential use in next-generation secondary battery development.

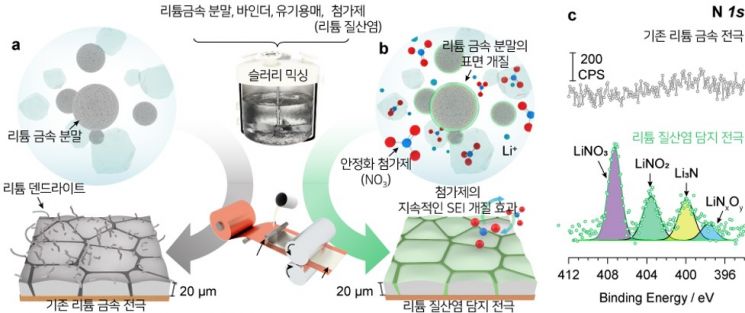

According to the research team, electrodes made from lithium metal have attracted interest as suitable anode materials for increasing battery energy density due to their high theoretical capacity (3860 mAh g-1) and low reduction potential (-3.04 V vs Li/Li+). However, during charge and discharge cycles, continuous formation of lithium dendrites causes the anode surface to become uneven, leading to performance degradation and battery fires caused by internal short circuits.

The research team developed a new anode manufacturing technology that suppresses these issues by adding a new material to the existing anode. For anode fabrication, the team mixed lithium nitrate, an interfacial protective additive, with lithium metal powder and induced uniform formation of the anode surface through solution-phase reactions. The lithium nitrate contained in the mold structure is gradually released into the electrolyte, ensuring continuous interfacial protection even during long-term battery use.

The developed anode has a thickness of 20 micrometers (㎛), and the joint research team confirmed through experiments that its lifespan characteristics improved by about 50 times compared to existing anodes under long-term usage conditions. It was verified that lithium dendrite formation is effectively suppressed and commercial battery-level lifespan characteristics can be secured.

Professor Lee Yong-min of DGIST’s Department of Energy Engineering explained, “The technology developed this time is a core technology capable of manufacturing ultra-thin, wide lithium metal electrodes and securing their performance, and it can be applied to various battery and electrolyte systems.”

The research results were published as a back cover paper on June 12 in the international academic journal in the field of energy materials, Advanced Energy Materials.

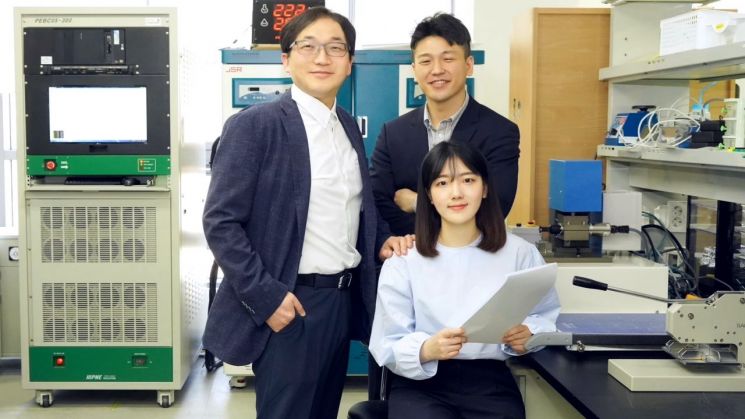

Professor Lee Yong-min (left), Professor Lee Hong-kyung (right), and PhD candidate Jin Da-hee (front row) from the Department of Energy Engineering at DGIST. Photo by DGIST

Professor Lee Yong-min (left), Professor Lee Hong-kyung (right), and PhD candidate Jin Da-hee (front row) from the Department of Energy Engineering at DGIST. Photo by DGIST

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)