Professor Hong Jeong-il's DGIST Team Develops Technology to Control Magnetic Self-Heating by Applying Mechanical Vibrations to Antiferromagnets

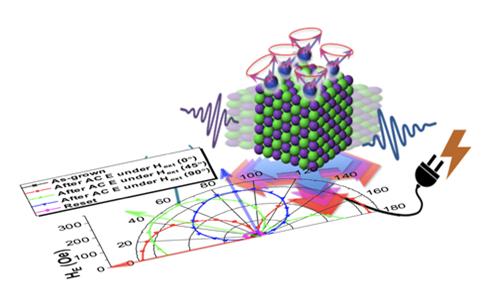

(Figure description) This indicates that the exchange bias characteristics, determined by atomic-level magnetic coupling and magnetic alignment states under mechanical vibrations applied to the material's crystal structure, can be set in multiple directions.

(Figure description) This indicates that the exchange bias characteristics, determined by atomic-level magnetic coupling and magnetic alignment states under mechanical vibrations applied to the material's crystal structure, can be set in multiple directions.

[Asia Economy Reporter Kim Bong-su] A technology has been developed to process antiferromagnetic materials, which are the materials for next-generation memory, more cost-effectively and efficiently than before.

The research team led by Professor Hong Jeong-il of the Department of New Materials Science at Daegu Gyeongbuk Institute of Science and Technology (DGIST) has developed for the first time a technology that effectively controls the magnetic alignment of antiferromagnets by applying mechanical vibrations instead of the conventional heat and magnetic fields.

Since the 1990s, spintronics electronics using magnetic materials have been actively developed to create next-generation memory and information processing devices capable of storing and processing more information. Spintronics is a technology that processes and stores information by electrically controlling the magnetic state of magnetic materials, enabling data processing much faster and more efficiently than conventional semiconductor devices using silicon.

Antiferromagnetic materials are combined with ferromagnetic materials and used in various spin devices, including next-generation memory called 'spin memory' that utilizes spintronics technology. Generally, the internal magnetic arrangement of ferromagnetic materials is aligned in the same direction, making it easy to control by using an external magnetic field to create the desired magnetic alignment state. However, the internal magnetic arrangement of antiferromagnetic materials is oriented in opposite directions, making control by external magnetic fields difficult. Therefore, to control antiferromagnetic materials, the exchange bias setting method, which uses heat and magnetic fields to create the desired magnetic alignment state of atoms, has been mainly used until now.

The problem is that due to the characteristics of devices with complex processors, it is difficult to control only specific parts, and there are limitations to thermal control because unwanted damage to other physical properties can occur.

The research team induced changes in magnetic coupling between atoms by applying fine mechanical deformation to the atomic crystal structure using mechanical vibrations without applying heat. They coated a thin film of antiferromagnetic material on a substrate made of piezoelectric materials that change shape when voltage is applied. When mechanical vibrations were applied through alternating voltage, the deformation of the piezoelectric material occurred simultaneously, and vibrations were transmitted to the coated antiferromagnetic thin film, allowing arbitrary changes to the internal magnetic alignment state. They also found that repeatedly applying this process could reset the magnetic coupling state.

This process, developed for the first time by the research team, is much more efficient than conventional thermal methods because it can be applied only to specific areas at room temperature. It enables resetting of devices whose magnetic alignment has deteriorated due to repeated operation, thereby enhancing durability through functional recovery of the device. The fine patterning of magnetic alignment also allows the design of spin devices with completely different operating mechanisms from existing devices.

Professor Hong Jeong-il said, "This is significant in that it presents a new setting method that overcomes the drawbacks and limitations of the conventional exchange bias setting method, increasing the potential for spintronics applications of antiferromagnetic materials," adding, "We will continue to understand and develop the control mechanisms of antiferromagnetic materials to advance research on new spin materials."

This research was published in the June 15 issue of 'Acta Materialia,' the most prestigious journal in the field of materials science.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.