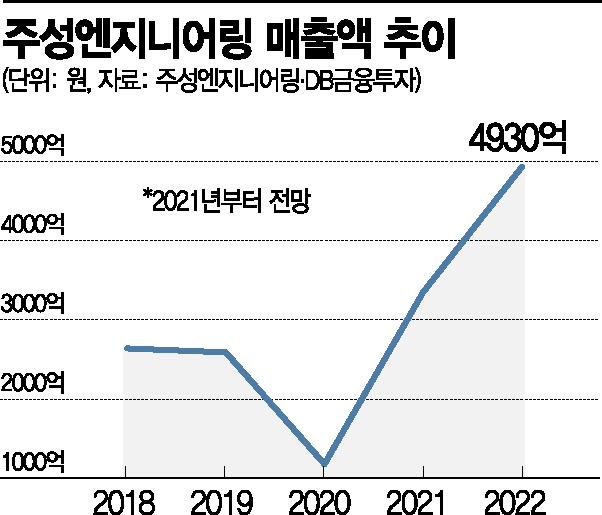

Quantum Jump Expected Amid This Year's Semiconductor Shortage... Order Backlog of 113 Billion KRW

R&D + Infrastructure Investment of 1.3 Trillion KRW... New Plant Expansion in July Next Year

Hwang Cheol-ju, CEO of Juseong Engineering (left), is inspecting the research center. [Photo by Juseong Engineering]

Hwang Cheol-ju, CEO of Juseong Engineering (left), is inspecting the research center. [Photo by Juseong Engineering]

[Asia Economy Reporter Junhyung Lee] Jusung Engineering experienced ups and downs last year due to the impact of COVID-19, but this year it is poised for a 'quantum jump' thanks to the semiconductor supercycle (long-term boom). Semiconductor equipment orders began to flood in from the fourth quarter of last year. This is because manufacturing equipment orders tend to concentrate during boom periods when facility investments are actively made. In addition, the company explained that the backlog of orders carried over to this year alone amounts to 113 billion KRW, and they have secured a considerable number of new clients.

Hwang Cheol-ju, CEO of Jusung Engineering, said, "The number of customers we have cultivated in the past two years far exceeds those secured over the 25 years since our establishment," adding, "This is thanks to the trust we have built so far and the company's innovative image."

According to the company on the 18th, sales in the first quarter of this year recorded 75.3 billion KRW, an increase of 113.9% compared to the same period last year (35.2 billion KRW). Operating profit turned positive to 16.1 billion KRW from a loss of 2.8 billion KRW in the same period last year.

Pursuing Innovation, Not Imitation... R&D Ratio Over 20%

Jusung Engineering is a company that manufactures semiconductor front-end equipment. It has established itself as a 'small but strong' company in the semiconductor front-end equipment industry, where global giants such as Applied Materials in the U.S. and ASML in the Netherlands dominate. Of course, it was not all 'rosy' from the start. This was due to the low trust in products from Korean companies that entered the semiconductor industry late. CEO Hwang explained, "In the early 1990s, not even a single domestically made screw was used in semiconductor manufacturing equipment," adding, "At that time, I worked at a global semiconductor equipment company but was not treated equally to overseas engineers and was regarded as a 'gofer.'"

CEO Hwang ultimately decided that independent technology development was necessary. After founding the company in 1993, he spent two years repairing semiconductor equipment to raise research and development (R&D) funds. By developing core technologies, the company began to acquire semiconductor equipment production capabilities from 1995. Three years later, it established a corporate-affiliated semiconductor research institute and accelerated R&D efforts.

During the technology development process, CEO Hwang was cautious about 'imitation.' This was influenced by the perception that Korean companies develop technology by imitating overseas technology, which made it difficult to secure initial customers. He also believed that competitiveness could not be achieved by merely following the leaders through imitation. CEO Hwang explained, "In the early days of the startup, overseas demand companies hesitated to contract with Korean equipment companies, fearing that their technology might be leaked," adding, "Even after securing innovative technology, it took a long time to build trust that 'we do not copy.'"

A Company That Competes with Technology, Not Price

As a result, Jusung Engineering has grown into a company that competes with technology rather than price. This contrasts with most domestic materials, parts, and equipment companies that succeeded in technology localization by emphasizing lower prices compared to foreign products. The unit price of the company's equipment is actually higher than that of global major equipment manufacturers. CEO Hwang emphasized, "Semiconductor customers do not switch from large equipment companies to Jusung Engineering to reduce costs," adding, "The only reason customers seek our equipment is because of our technological capabilities." In fact, Jusung Engineering was the first in the world to develop 18 process technologies, including manufacturing equipment for key semiconductor components such as transistors (switches that control current and voltage) and capacitors (devices that store charge), and holds 2,167 related patents, ranking first in the domestic industry.

This reflects CEO Hwang's strong commitment to R&D. Of the approximately 500 employees, 66.4% are engaged in R&D. While the R&D investment ratio relative to sales for the global top 5 equipment companies averaged around 15%, Jusung Engineering has exceeded 20% annually. The total investment in R&D since establishment amounts to about 800 billion KRW. Including infrastructure costs such as the Yongin R&D center, the total exceeds 1.3 trillion KRW.

To expand production capacity, the company recently decided on a new facility investment worth 36.3 billion KRW. This is because the demand growth in the display industry, another growth engine for the company besides semiconductors, is also significant. With this decision, a new factory with a total floor area of 21,700 square meters will be added to the headquarters located in Gwangju, Gyeonggi Province, by July next year. CEO Hwang stated, "As time goes by, semiconductor demand increases," adding, "The solution to the (semiconductor) shortage ultimately lies in facility investment."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)