KIMM Researchers Develop Structural Health Monitoring System for Measuring Natural Frequency

[Asia Economy Reporter Kim Bong-su] The Korea Institute of Machinery and Materials (KIMM) announced on the 21st that it has developed a Structural Health Monitoring system (SHM) that can more effectively diagnose the safety of offshore wind turbines installed in our seas.

With growing interest in renewable energy to achieve carbon neutrality goals, this system allows offshore wind farms to be operated more economically and safely, thereby helping to strengthen the competitiveness of wind energy.

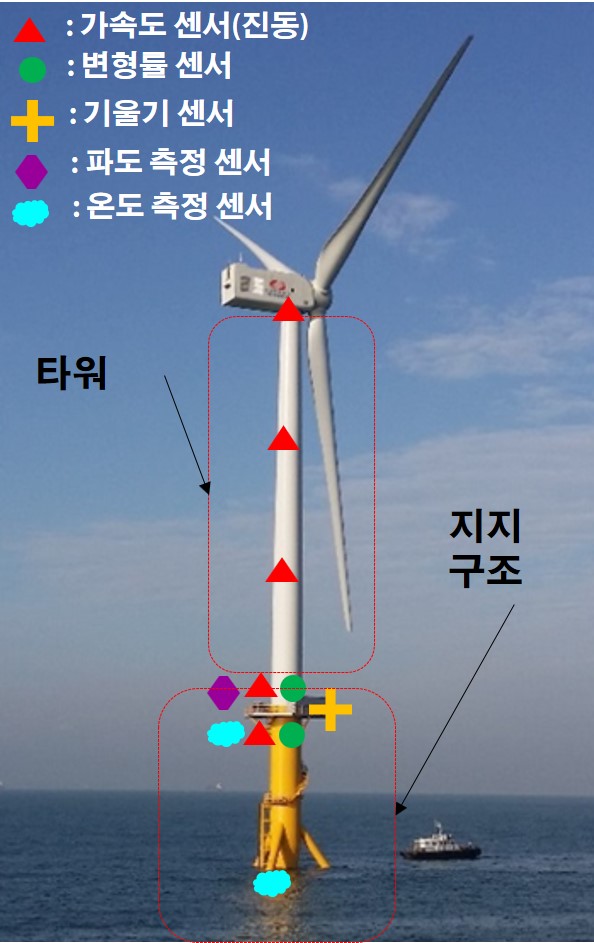

Senior Researcher Seo Yun-ho of KIMM’s System Dynamics Laboratory developed the SHM system that precisely detects the structural condition by utilizing the natural frequency of offshore wind turbines installed in the sea. This system monitors safety by measuring various information to prevent accidents that can occur in large structures such as buildings and bridges. It employs various technologies ranging from real-time measurement and online monitoring of physical quantities such as vibration and strain of structures, to periodic offline inspections including visual inspections and non-destructive testing that require direct observation.

The structural stability of wind turbines is greatly affected by the loads generated as the blades rotate. Especially since they are installed on the seabed, factors such as currents, waves, corrosion caused by seawater, and erosion of the seabed terrain also impact the structure, so the supporting structure must be robust.

The research team developed a technology that detects the natural frequency of the structure in real time to effectively diagnose the safety of the wind turbine’s supporting structure. Natural frequency refers to the inherent frequency of vibration that every structure possesses; all structures vibrate at their natural frequency (frequency) when subjected to external shocks. Instruments like pianos, xylophones, and bronze bells also produce sound due to their natural frequencies.

The team succeeded in estimating the subtly changing natural frequency based on various sensor data such as the operational status, power generation, and rotational speed of the offshore wind turbines. Until now, various sensor data had to be analyzed individually to monitor the structural health, but now safety diagnosis is possible simply by measuring the natural frequency.

The research team installed this system on suction bucket-supported offshore wind turbines, which have recently attracted attention as an eco-friendly construction method, and conducted data acquisition and monitoring performance verification over one year. The results showed that safety diagnosis could be performed efficiently, reducing operational personnel and costs.

Senior Researcher Seo Yun-ho of KIMM said, “By utilizing this technology, we can dramatically enhance the operational safety of offshore wind farms and contribute to expanding the use of eco-friendly and economical wind energy. Our technology enables structure monitoring optimized for our terrain, allowing the creation of efficient and safe power generation systems.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.