Gwangju Institute of Science and Technology Professor Changhyuk Choi's Team Develops Performance Measurement Technology for Single-Atom Catalysts to Replace Platinum

[Asia Economy Reporter Kim Bong-su] The development of hydrogen fuel cells is a key task in future renewable energy technologies. Although electric vehicles are emerging, electricity production still largely depends on thermal power generation, which emits a significant amount of carbon dioxide. One of the technical challenges in developing hydrogen fuel cells is that the catalyst used to produce electricity by reacting hydrogen with oxygen is platinum, a rare precious metal. Due to its high cost and scarcity, it is difficult to commercialize. Accordingly, research on developing inexpensive catalysts is underway, and a domestic research team has secured foundational technology to develop catalysts made from much cheaper materials such as iron, nitrogen, and carbon instead of platinum.

The Gwangju Institute of Science and Technology (GIST) announced on the 19th that Professor Choi Chang-hyuk’s research team from the Department of New Materials Engineering has secured foundational technology for performance evaluation of non-precious metal catalysts for hydrogen fuel cells.

As a catalyst for hydrogen fuel cells that can replace platinum, single-atom iron-based catalysts composed of iron, nitrogen, and carbon are attracting attention as efficient oxygen reduction reaction catalysts. The problem is that there is no technology to diagnose the performance of single-atom iron-based catalysts. Therefore, it has been difficult to identify key catalyst performance factors such as active site density and turnover frequency. Active site density refers to the density of sites on the catalyst surface where reactants undergo catalytic action, and turnover frequency is the number of molecules reacting per active site of the catalyst per unit time.

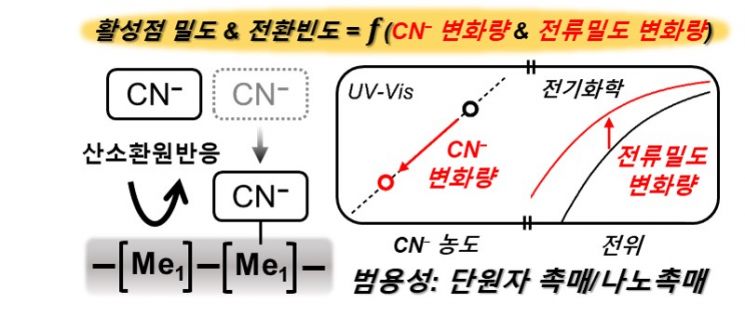

The research team devised a technology to measure the catalyst performance factors of active site density and turnover frequency by focusing on the fact that cyanide ions (CN-) can irreversibly adsorb onto iron-based single-atom catalysts. Using a specially designed reactor, cyanide ions were irreversibly adsorbed onto the iron-based single-atom catalyst. The amount of adsorbed cyanide ions was quantified using ultraviolet-visible (UV-Vis) spectroscopy. Simultaneously, the decrease in oxygen reduction reactivity of the catalyst with irreversibly adsorbed cyanide ions was measured, and through this, the active site density and turnover frequency of the catalyst were successfully derived.

Professor Choi Chang-hyuk stated, “The greatest significance of this research achievement is that we have secured foundational technology for performance evaluation of iron-based single-atom catalysts, which are approaching commercialization.” He added, “We hope that by utilizing this technology in the future to develop highly active oxygen reduction catalysts, we can contribute to the activation of the future hydrogen economy.”

The research results were published online on the 13th in the international journal ‘JACS Au,’ an open-access journal published by the American Chemical Society (ACS).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)