[Asia Economy Reporter Hwang Yoon-joo] LG Energy Solution is establishing a second electric vehicle battery joint plant with GM (General Motors), the number one automobile company in the United States, to expand the U.S. electric vehicle market.

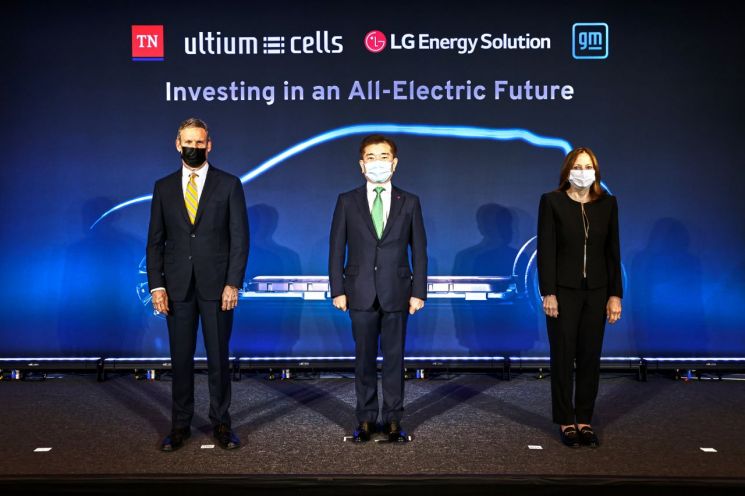

On the 16th (local time), LG Energy Solution held an investment announcement event for the second joint plant at the State Museum located in Nashville, Tennessee, attended by GM Chairwoman Mary Barra, Tennessee Governor Bill Lee, and LG Energy Solution President Kim Jong-hyun.

The two companies plan to invest a total of 2.7 trillion KRW in the second joint plant through their joint venture, Ultium Cells, aiming to secure a production capacity of over 35GWh by the first half of 2024. The project will create 1,300 jobs.

The plant site is located in the Spring Hill area of Tennessee. Construction will begin within this year, with mass production planned for the second half of 2023. Together with the first joint plant, the batteries produced will be supplied to GM’s next-generation electric vehicles.

Mary Barra, GM Chairwoman, stated, "Building a second battery plant in the U.S. with our joint partner LG Energy Solution is another major step in our transition to an electric vehicle future."

Kim Jong-hyun, President of LG Energy Solution, said, "We will actively expand electric vehicles with our top partner GM and greatly contribute to the success of the U.S. Green New Deal policy," adding, "We will focus even more on establishing a differentiated and stable supply chain system within the U.S., not only in battery production but also from R&D to product development and raw material procurement."

GM-LG Secure 70GWh Production Capacity Through Joint Plants

Through this investment, GM and LG Energy Solution will secure a large-scale electric vehicle battery production capacity in the U.S. The two companies are currently constructing a 35GWh battery first joint plant in Ohio, and will additionally establish a second joint plant of the same scale in Tennessee.

By 2024, GM and LG Energy Solution will have a total battery production capacity of over 70GWh across the two joint plants, which is enough to produce one million high-performance pure electric vehicles capable of driving over 500km on a single charge.

Meanwhile, the U.S. electric vehicle market is considered one of the world’s top three electric vehicle markets alongside China and Europe, and is growing rapidly. According to market research firm SNE Research, the U.S. electric vehicle market is expected to grow from 1.1 million units this year to 2.5 million units in 2023 and 4.2 million units in 2025, with an average annual growth rate of 40%.

Key Base for Building U.S. Green Energy Infrastructure

LG Energy Solution’s rapid expansion of electric vehicle battery production capacity is to actively support the U.S. government’s eco-friendly policy direction and GM’s electric vehicle expansion plans as a partner.

The U.S. has recently been implementing the Green New Deal policy in earnest. To achieve carbon neutrality by 2050, it plans to invest $2 trillion over four years in the green energy sector. The government will replace 3 million official vehicles with electric vehicles and introduce a policy for local governments to purchase 500,000 electric school buses. Additionally, policies to drive market demand include expanding purchase incentives for electric vehicles and installing 500,000 electric vehicle charging stations.

Furthermore, the reshoring policy called 'Buy America' is also in operation. A punitive tax of 10% is imposed on electric vehicles sold in the U.S. that are not made in America. A key requirement for American-made electric vehicles is local production of battery cells.

GM, the number one automaker in North America, is also actively expanding the North American and global electric vehicle markets in line with these changes. GM plans to launch about 30 global electric vehicle models by 2025, with around 20 of these models to be sold in North America.

By 2025, GM aims to have 40% of its vehicle sales be electric vehicles, targeting sales of over one million electric vehicles and becoming the number one electric vehicle seller in the North American market. To achieve this goal, GM has increased its investment in electrification and autonomous driving from $20 billion to $27 billion by 2025.

The U.S. electric vehicle battery plant, invested in by LG Energy Solution and equipped with large-scale production capacity, is expected to become a key base supporting GM’s goal of being number one in North American electric vehicles as well as the U.S. government’s eco-friendly policies.

LG Energy Solution to Secure 145GWh Production Capacity in the U.S. by 2025

Meanwhile, LG Energy Solution recently announced that in addition to the joint plant with GM, it plans to independently invest over 5 trillion KRW by 2025 to secure an additional battery production capacity of over 70GWh solely in the U.S.

Once this investment is made, LG Energy Solution’s independent production capacity will increase to a total of 75GWh, including the existing Michigan plant (5GWh). Combined with the 70GWh from the joint plants with GM, the total production capacity in the U.S. will reach 145GWh. This is enough to produce over two million high-performance pure electric vehicles.

Currently, LG Energy Solution holds the world’s largest production capacity of 120GWh in the global market. It plans to continuously expand electric vehicle battery production capacity not only in the U.S. but also in Korea, Poland, and China, aiming to secure 260GWh of electric vehicle battery production capacity by 2023. The 260GWh capacity is enough to produce over 3.7 million high-performance pure electric vehicles.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.