Sangui Evaluates Future Readiness of Petrochemical Industry... 'Lower-Mid' Among 8 Assessed Sectors

Industry Proposes "Expansion of Investment Tax Credits, Support for Alternative Raw Material Investment, Training of Petrochemical Process Experts"

[Asia Economy Reporter Hwang Yoon-joo] The petrochemical industry, one of the core key industries of Korean industry, has been pointed out as urgently needing countermeasures due to insufficient future preparedness compared to other industrial sectors.

The Korea Chamber of Commerce and Industry held the 3rd Future Industry Forum on the 15th to assess the level of digital transformation and carbon neutrality response capability of the petrochemical industry.

The petrochemical industry showed relatively poor performance in both 'digital transformation' and 'carbon neutrality.' According to the rankings revealed at the meeting, among the eight industries evaluated, the petrochemical industry ranked 5th in digital transformation and 6th in carbon neutrality.

In the petrochemical industry, 'catalyst technology' has long served as a core competitive advantage, leading to a passive stance toward innovation such as the adoption of digital technologies. Additionally, due to the industry's characteristic of using petroleum as raw material, there were many constraints in achieving carbon reduction in a short period.

Stable Production and Distribution Structure Slows Change... Time for a 'Deep Shift'

Choi Yong-ho, Managing Director at Deloitte Consulting, who gave the first presentation, said, "For over a century, catalyst technology has been the key factor determining the quality, yield, and productivity of petrochemical products," adding, "There was no particular need for innovation outside of technology, which resulted in poor digital maturity."

Managing Director Choi explained, "Especially, the Korean petrochemical industry has mainly produced generic products and had a high proportion of B2B distribution channels, so there was little need to utilize big data to improve quality or understand customer needs," adding, "This is why digital utilization was insufficient across the petrochemical sector."

Finally, Managing Director Choi emphasized, "Global leading chemical companies recognize digital capabilities as future competitiveness and are actively investing. Domestic companies should now decide and promote the direction, speed, and scope of digital transformation according to their individual circumstances."

As a digital transformation strategy for the petrochemical sector, seven tasks were proposed in three major areas: ▲ integrated supply chain management and automation ▲ digitalization of field management ▲ maximizing yield through production optimization.

The second presentation was given by Jung Eun-mi, Director at the Korea Institute for Industrial Economics and Trade, on the current status of greenhouse gas emissions and carbon neutrality in the petrochemical industry.

Director Jung emphasized, "The petrochemical industry is a representative greenhouse gas emitting industry, with direct emissions from naphtha raw materials accounting for 64% of the total, so replacing naphtha raw materials is key to responding to carbon neutrality."

She continued, "Attempts are underway to replace naphtha raw materials with hydrogen, bio, and others to reduce greenhouse gas emissions, but practical issues such as costs and technology development remain," stressing, "More efforts are needed in R&D for alternative raw materials."

Need for Environmental Regulations to Enable Rapid Chemical Industry Structural Reform

The final presentation was given by Jang Seok-in, Chair Professor at Korea University of Technology and Education, who said, "Recently, the chemical industry is rapidly changing its industrial structure toward eco-friendly chemical products and high value-added fine chemicals," adding, "Environmental regulations must also be improved accordingly to enable effective responses."

Professor Jang cited the Industrial Safety and Health Act as an example, pointing out, "The inspection cycle for safety valves is determined based on the evaluation grade of the factory safety report implementation status, but sometimes the inspection cycle is shortened even if the grade drops for reasons unrelated to safety valves," and explained, "Most safety valves are located at high places, so more inspections increase the risk of serious accidents and make securing working hours difficult, which lowers trust in inspections."

He added, "In most advanced countries, inspection cycles for large refinery and petrochemical facilities are not legally mandated but are set according to the facility's own procedures," and said, "Inspection cycles and standards should be rationalized to ensure the reliability of safety valve inspections."

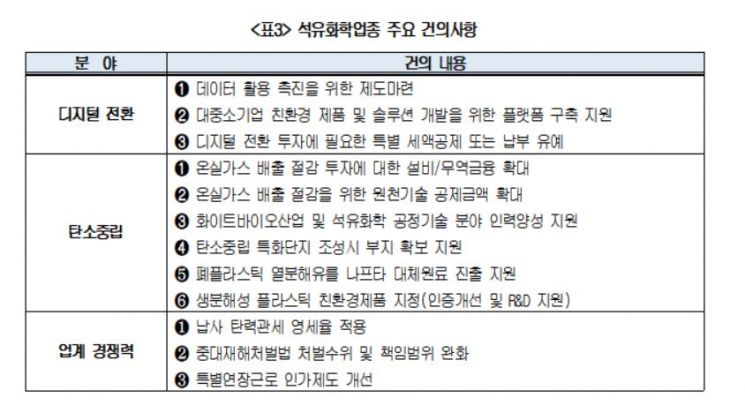

During the subsequent open discussion, industry representatives made suggestions regarding the presentations.

Song Yoo-jong, Executive Vice President of the Korea Petrochemical Industry Association, said, "The petrochemical industry is also establishing a digital transformation vision and attempting to integrate digital technologies across R&D, procurement, and the entire value chain," adding, "The government needs institutional efforts such as reducing restrictions on data use to promote corporate digital transformation."

Regarding carbon neutrality, he emphasized, "To achieve carbon neutrality by 2050, the petrochemical industry must replace not only raw materials and fuels but also related facilities," adding, "Since financial burdens such as technology development are critical, the government must drastically increase financial and tax support."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.