Domestic Research Team Develops Glucose Extraction Method to Replace Expensive and Inefficient Lac Insects

[Asia Economy Reporter Kim Bong-su] A new technology capable of isolating the red edible pigment (carminic acid), widely used in food and cosmetics, from glucose has been developed by a domestic research team. Previously, it was only extractable from cochineal insects cultivated in South America, making it costly and potentially allergenic, thus limiting its use.

The Korea Advanced Institute of Science and Technology (KAIST) announced on the 9th that a research team led by Distinguished Professor Lee Sang-yeop of the Department of Bio and Chemical Engineering succeeded in developing a microbial strain that produces the red natural pigment "carminic acid," widely used as a food additive.

Carminic acid is a red natural pigment extensively used in foods such as strawberry milk and candies, as well as in cosmetics like nail polish and lipstick. Until now, carminic acid could only be obtained through extraction from cochineal insects.

The problem is that cochineal insects can only be cultivated in limited regions (such as Peru and the Canary Islands), and extracting carminic acid from them requires a complex and inefficient multi-step process. Moreover, the pigment often contains protein contaminants derived from the cochineal insects, which can trigger allergic reactions and deter many consumers. For these reasons, some franchise companies have ceased using carminic acid and have switched to alternative edible colorants.

Although the need for alternative production methods has been raised, part of the synthetic pathway remains unknown, and carminic acid production has not been reported in microorganisms other than fungi.

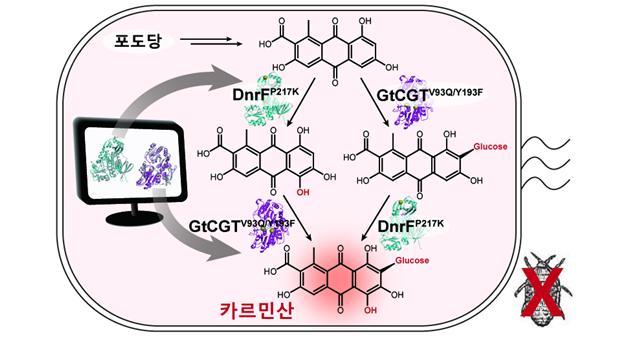

The research team succeeded in developing an Escherichia coli strain capable of producing carminic acid from glucose. First, they optimized type II polyketide synthase to construct an E. coli strain that produces the precursor (an intermediate substance) of carminic acid. However, enzymes required for the remaining two reaction steps had not yet been discovered or did not function within E. coli. To address this, the team selected candidate enzymes for carminic acid production through biochemical reaction analysis. Subsequently, they identified enzymes that functioned successfully through cell culture experiments.

For the two selected enzymes, computer-based homology modeling and docking simulations were performed to predict mutant enzymes with enhanced activity. Based on this, enzyme improvement was carried out, successfully developing enzymes with increased activity.

This marks the first development of an E. coli strain that produces carminic acid using glucose?a primary raw material of the most abundant biomass on Earth, including waste wood and weeds?as a single carbon source. The metabolic engineering and virtual simulation-based enzyme improvement strategy developed by the research team is expected to be useful for producing other natural products whose biosynthetic pathways have not been elucidated. The team demonstrated this by applying the C-glycosyltransferase developed in this study to successfully produce aloesin, a whitening agent previously producible only from aloe, for the first time worldwide.

Professor Lee Sang-yeop stated, "We have developed the world's first carminic acid production process that does not use cochineal insects. This research is significant because it provides an effective solution to the chronic problems of enzyme discovery and improvement in natural product biosynthesis," adding, "Using this technology, it will be possible to efficiently produce various medically or nutritionally important natural products."

The research results were published online on June 2 in the international journal Journal of the American Chemical Society.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.