KIST "Develops New Concept Parts to Greatly Improve Driving Efficiency"

[Asia Economy Reporter Kim Bong-su] Recently, green hydrogen, which is produced without generating carbon dioxide as part of renewable energy, has been gaining attention. In this context, a domestic research team has attracted interest by significantly improving the efficiency of an integrated renewable fuel cell capable of both green hydrogen production and power generation.

The Korea Institute of Science and Technology (KIST) announced on the 26th that a joint research team led by Dr. Park Hyun-seo of the Hydrogen and Fuel Cell Research Group solved the problem of water and gas mixing and moving slowly within a cyclic operation device for hydrogen production and hydrogen-utilizing power generation through the development of a new concept component, greatly enhancing operational efficiency.

The integrated renewable fuel cell can operate both hydrogen production and fuel cell power generation. It offers cost and spatial advantages compared to installing separate water electrolysis (producing hydrogen by electrolyzing water) and fuel cell devices. When electricity production from renewable energy sources such as solar and wind exceeds demand, hydrogen is produced via electrolysis to store energy. Conversely, when power demand is higher, the device can supply electricity by operating as a fuel cell. For rapid hydrogen production through electrolysis, water must quickly reach the catalyst layer at the electrode, and the generated hydrogen and oxygen must also be quickly released. The same applies during fuel cell operation.

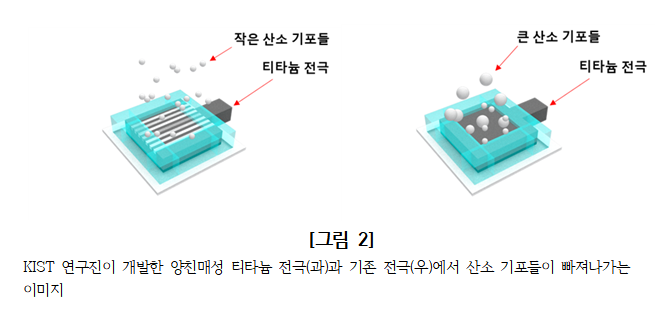

The research team focused on the phenomenon in the integrated device where water and gas repeatedly enter and exit during alternating electrolysis and fuel cell operations, causing partial water accumulation or gas blockage that reduces efficiency. They determined that hydrophilic electrodes are needed to draw water quickly, and hydrophobic electrodes are necessary for rapid gas movement.

To create electrodes with the contradictory properties of being both hydrophilic and hydrophobic, the team coated the electrode surface with micro-patterned plastic that alternates between hydrophilic and hydrophobic regions. This gave the electrodes simultaneous water-repelling and water-attracting characteristics, enabling smooth movement of both water and gas. On the developed electrode surface, gases were selectively released up to 18 times more easily.

When applying the newly developed components to the integrated device, the research team confirmed that fuel cell operation performance increased fourfold and hydrogen production doubled compared to using conventional components. They also verified stability through 160 hours of continuous operation.

Dr. Park Hyun-seo of KIST said, “This is the first application of amphiphilic electrodes, which demonstrate stable and high performance in both fuel cell power generation and water electrolysis green hydrogen production, to integrated renewable fuel cell electrodes.” He added, “We expect this principle to be applicable to other fields such as electrochemical carbon dioxide reduction cells and nitrogen reduction cells, where gas and liquid simultaneously enter.”

The research results were published in the latest issue of the international scientific journal Science Advances.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.