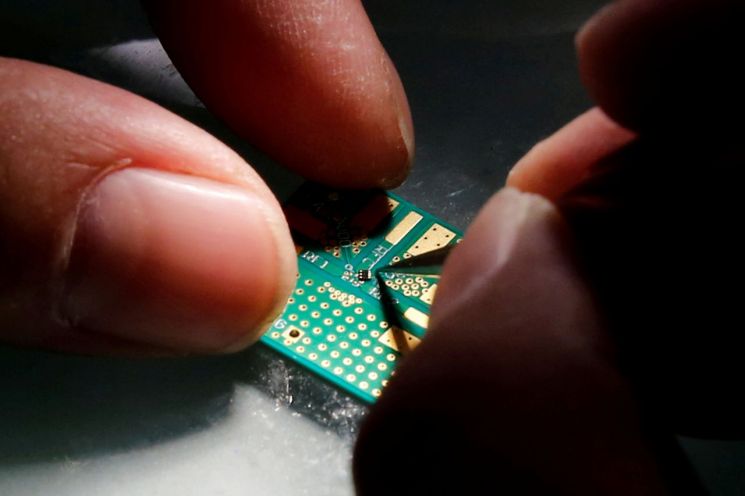

[Asia Economy Reporter Jeong Hyunjin] Amid the ongoing global semiconductor shortage, a fire broke out at the main factory of Japanese semiconductor company Renesas Technology, halting the production line for automotive semiconductors. With the semiconductor supply shortage already impacting the production of automobiles, smartphones, and other products, this fire could further exacerbate the situation.

According to the Nihon Keizai Shimbun on the 20th, the fire occurred the previous day on the first floor of Renesas Technology's main Naka plant located in Hitachinaka City, Ibaraki Prefecture. The plant produces advanced 300mm semiconductor wafers, primarily manufacturing automotive semiconductors that control vehicle driving, the Nihon Keizai explained. Fortunately, other buildings, including the 200mm wafer production line, were reportedly unaffected.

Renesas has established an emergency response headquarters and began on-site inspections from the morning of the same day. After assessing the situation, they plan to consider future countermeasures. Due to the presence of toxic gases at the fire site, it is expected to take some time to fully assess the damage. A Renesas official stated that the timing for resuming production is "currently unpredictable."

The fire at Renesas's main factory is likely to intensify the prolonged semiconductor shortage. Renesas had shifted some semiconductor production, previously outsourced to external companies such as Taiwan's TSMC, to in-house manufacturing to ensure stable supply amid the global shortage of automotive semiconductors. The factory building where the fire occurred is responsible for mass production of advanced products transferred from TSMC.

This situation is similar to the production difficulties faced by semiconductor companies, including TSMC, caused by the shutdown of semiconductor plants in Texas due to a cold wave in the U.S. and water shortages from droughts in Taiwan, which have further impacted semiconductor supply. Since February, Samsung Electronics' Austin semiconductor plant has been shut down for over a month. Consequently, the supply of organic light-emitting diode (OLED) and image sensor semiconductors produced at this plant is also expected to be affected.

In addition to Samsung Electronics, automotive semiconductor plants such as the Netherlands' NXP and Germany's Infineon closed their factories last month. As a result, major automobile manufacturers like Tesla and Honda have announced production halts due to the semiconductor shortage. Infineon recently estimated that it will not recover to pre-shutdown production levels until June. Meanwhile, Taiwan has been experiencing a severe drought since last month, prompting major semiconductor manufacturers like TSMC to deploy water tank trucks to secure the essential water supply for semiconductor production.

If the shutdown at Renesas's factory continues for an extended period under these circumstances, the impact on automobile production could spread further. The Nihon Keizai noted that when this factory was damaged by the Great East Japan Earthquake in 2011, the clean rooms and equipment were destroyed, causing about a three-month suspension of operations and significantly affecting automobile production. They also explained that in February this year, operations were temporarily halted due to a power outage caused by an earthquake off the coast of Fukushima Prefecture.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)