KRICT and ChemTros Co., Ltd. Sign Technology Transfer Agreement for PFSA Localization on the 16th

[Asia Economy Reporter Kim Bong-su] The localization technology for perfluorosulfonic acid ionomer (PFSA), a core material of hydrogen fuel cell vehicles, has entered the commercialization stage.

The Korea Research Institute of Chemical Technology (KRICT) signed a technology transfer agreement with ChemTros Co., Ltd. on the afternoon of the 16th at the Daejeon Chemical Research Institute conference room to localize PFSA. PFSA (Perfluorosulfonic Acid) is a polymer composed entirely of fluorocarbons (C, F) that functions as a proton (H+) conductor. It is used in hydrogen vehicles, energy storage systems (ESS), distributed power sources, and electrolyzers.

Hydrogen vehicles are considered one of the next-generation transportation means that can achieve carbon neutrality by emitting no environmental pollutants, and the government plans to foster the hydrogen vehicle industry. According to the Ministry of Trade, Industry and Energy's 2019 Hydrogen Economy Activation Roadmap, South Korea plans to expand its hydrogen vehicle production scale to 81,000 units annually by 2022 and 6.2 million units by 2040.

Hydrogen vehicles operate on the principle that water is emitted and electricity is generated through the chemical reaction of hydrogen and oxygen in the fuel cell. Therefore, the electrolyte membrane that allows hydrogen ions to pass through and react with oxygen in the fuel cell is crucial. The manufacturing process of the PFSA electrolyte membrane is a technology that integrates all fluorochemical technologies, involving many sensitive variables such as moisture, temperature, and explosiveness. The manufacturing process is very complicated and lengthy, so only a few global companies such as DuPont, AGC, and Solvay can produce it.

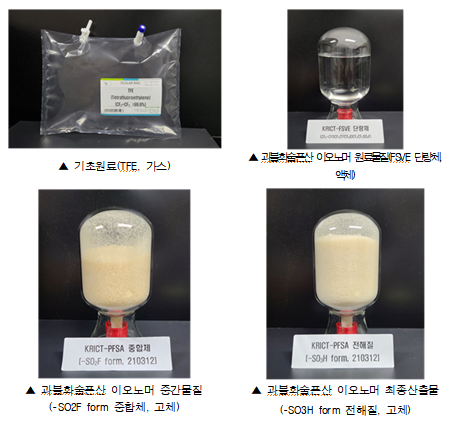

Currently, South Korea relies entirely on imports. This is because it is necessary to secure all technologies including the basic raw materials tetrafluoroethylene (TFE), hexafluoropropylene oxide (HFPO), intermediate fluorinated (-COF) compounds, perfluorosulfonic acid monomers, fluorine-based initiators, final material (fluoropolymer) manufacturing technology, and reliability verification technology.

The ‘Fluorochemical Materials Process National Research Laboratory (19F-N-LAB)’ affiliated with KRICT developed the PFSA synthesis technology for the first time in Korea in 2018 based on over 30 years of accumulated research capabilities in fluorine compounds, and has continued to study production processes for commercialization since then.

The laboratory optimized a total of nine manufacturing steps necessary for commercialization, including the basic raw material manufacturing process of perfluorosulfonic acid ionomer and the manufacturing process of perfluorosulfonic acid ionomer from monomers, and transferred the technology to ChemTros Co., Ltd. Currently, the laboratory is working with ChemTros to design and construct a commercial production plant with an annual capacity of 100 tons, aiming to start production in the first half of 2022, and to conduct long-term stability evaluations of prototypes. The 100 tons corresponds to the amount that can be used by 100,000 passenger cars for one year.

Park In-jun, the lead researcher at KRICT, said, “The PFSA manufacturing process has a high entry barrier and is only possessed by a few advanced countries such as the United States, Japan, and Belgium.” He added, “It is meaningful to have developed this as a domestic independent technology, and we will continue follow-up research with companies to ensure smooth commercialization in the future.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.