Ulsan National Institute of Science and Technology and Sungkyunkwan University Team Jointly Achieve Success

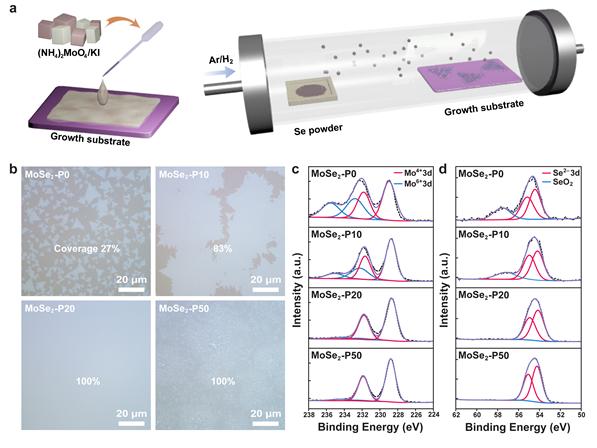

Synthesis of molybdenum diselenide via chemical vapor deposition (CVD) method. (a) Schematic of liquid precursor-based chemical vapor deposition method including a promoter. (b) Optical images and (c, d) XPS analysis of molybdenum diselenide according to promoter concentration. Provided by Ulsan National Institute of Science and Technology.

Synthesis of molybdenum diselenide via chemical vapor deposition (CVD) method. (a) Schematic of liquid precursor-based chemical vapor deposition method including a promoter. (b) Optical images and (c, d) XPS analysis of molybdenum diselenide according to promoter concentration. Provided by Ulsan National Institute of Science and Technology.

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed a technology to grow two-dimensional semiconductor materials (materials as thin as an atomic layer) widely and uniformly. The transition metal chalcogenide compounds synthesized using this technology are large enough and have excellent crystallinity to be used in semiconductor device fabrication, which is analyzed as good news for the commercialization of next-generation semiconductor materials that can replace silicon.

On the 8th, Ulsan National Institute of Science and Technology (UNIST) announced that Professor Park Hye-sung’s team from the Department of Materials Science and Engineering, in collaboration with Professor Kang Joo-hoon’s team from Sungkyunkwan University, developed a technology to synthesize transition metal chalcogenide compounds with excellent crystallinity by using both liquid and solid precursors, unlike the conventional method that uses only solid fuel. They solved the problem of decreased crystallinity of synthesized materials when using liquid precursors by employing a promoter.

Transition metal chalcogenide compounds are attracting attention as next-generation semiconductor materials, but large-area synthesis is challenging. The method of synthesizing using solid precursors that turn into vapor at high temperatures results in irregular vapor concentration, making it difficult to obtain multiple thin films of the same quality, and there is a limit to the size that can be synthesized. For this reason, methods using liquid precursors have been gaining attention, but when liquid precursors are used, there is a problem of reduced quality such as crystallinity of the synthesized material.

The research team used a method of coating liquid transition metal precursors on a substrate to react with vapor-phase chalcogen elements. The promoter (metal halide) in the liquid precursor facilitates the chalcogenization chemical reaction, enabling easy synthesis of compounds with excellent crystallinity. Also, by using the promoter, the compound grows only in the horizontal direction rather than vertically, allowing the synthesis of transition metal chalcogenide compounds consisting of a single thin layer.

The developed synthesis method can be applied regardless of the type of transition metal chalcogenide compound. The research team synthesized various monolayer transition metal chalcogenide compounds by changing combinations of transition metals such as molybdenum (Mo) and tungsten (W) and chalcogen elements such as sulfur (S) and selenium (Se).

The researchers also succeeded in fabricating semiconductor devices using the synthesized semiconductor thin films. They fabricated a field-effect transistor using a molybdenum diselenide (MoSe2) thin film and confirmed the excellent electrical properties (electron mobility) of the thin film.

Professor Park Hye-sung said, "The developed synthesis method is a technology that can produce large-sized, high-performance, and uniform-quality two-dimensional semiconductor materials suitable for commercialization," and added, "It is expected to contribute to the development and commercialization of electronic devices based on two-dimensional materials."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)