Last Year Domestic Sales Plummeted to Foreign Exchange Crisis Levels... Could It Be the Worst Ever?

[Asia Economy Reporter Kim Jong-hwa] A sense of crisis is spreading in the cement industry.

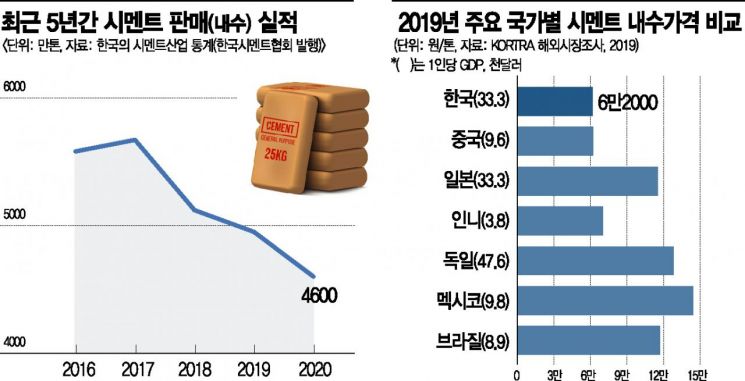

On the 28th, the Korea Cement Association's provisional tally showed that last year's domestic shipment (sales) performance of the cement industry was 46 million tons, deteriorating to a level close to 44.6 million tons during the International Monetary Fund (IMF) foreign exchange crisis, which was the lowest ever.

If the domestic demand decline rate of 7.1% last year continues this year, domestic sales will sharply drop to 43 million tons. In this case, this year could become the worst year in the history of the cement industry, surpassing the IMF foreign exchange crisis, and the sense of crisis is growing.

The industry sees three key issues that must be resolved this year to improve the uncertain business environment and overcome the crisis: ‘realistic cement pricing,’ ‘blocking the legislation of the local resource facility tax,’ and ‘solving environmental problems through recycling of circular resources.’

Realistic Cement Pricing Needed, Cost Reduction Efforts Also at Limit

Domestic cement is sold at one of the lowest prices in the world. In a situation where demand is decreasing, low cement prices are the biggest obstacle for the cement industry.

Last year, cement prices were traded at an average of 65,000 to 67,000 KRW per ton (including VAT). This is a decline from 67,000 to 69,000 KRW in 2019.

Recently, the international price of bituminous coal, a major fuel entirely imported from overseas, surged by 37.7% over six months. According to the Korea Resource Information Service, the price of bituminous coal rose from 52.9 USD per ton in July last year to 72.8 USD in December. Bituminous coal accounts for more than 30% of manufacturing costs. Prices of various raw and subsidiary materials are also rising, but many of these increases have not been reflected in product prices.

An industry official said, "The cement industry was able to endure without raising prices thanks to cost reduction efforts such as waste heat power generation operation," adding, "Now, even this has reached its limit."

Additional Burden from Various Environmental Taxes, Blocking Local Resource Facility Tax Legislation

The local resource facility tax, which imposes a tax of 1,000 KRW per ton of cement production to support residents around cement plants, is claimed by the industry to be "populism by local governments trying to shift local fiscal shortages onto hometown companies."

If the related bill passes the National Assembly, the industry will have to pay more than 50 billion KRW in additional taxes annually. With strengthened environmental regulations, the industry already bears costs exceeding 100 billion KRW annually for carbon emission rights, nitrogen oxide emission charges, and cargo truck safety freight systems. Adding 50 billion KRW more will inevitably increase management uncertainty.

An industry official pointed out, "Although it was automatically discarded in the last National Assembly due to various problems such as overlapping taxation under the same name, it has been revived in this National Assembly," and added, "For over 30 years, the limestone mining local resource facility tax has been paid to Gangwon-do and Chungcheongbuk-do, but it has not been disclosed whether the local governments have used the tax as originally intended."

Circular Resource Recycling as an 'Environmental Problem Solver'

The cement companies recycled 70% of the waste from the ‘Uiseong Garbage Mountain,’ which was internationally shamed after being reported by CNN in 2019, as fuel in their production processes. The cement industry has emerged as an environmental problem solver.

Cement, manufactured by heating and melting mineral raw materials such as limestone at ultra-high temperatures of 1450~2000℃, inevitably generates greenhouse gases due to the nature of the raw materials. However, domestic cement companies have been helping solve environmental problems through ‘circular resource recycling,’ which produces cement by recycling various industrial wastes since the 1990s.

Professor Kang Tae-jin of Seoul National University said, "The recycling rate of circular resources in German cement plants reaches 65%, but ours is only 20%," adding, "We can also raise the national status through circular resource recycling."

An industry official appealed, "The safety and excellence of circular resource recycling have been proven in Europe and Japan. However, the domestic cement industry, which possesses better technology, is being intimidated by some unfounded harmful claims," and added, "The distorted views of some local governments and environmental groups must be corrected, and government policy support is absolutely necessary."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.