Implementation of Metamaterial Lens Using Nanoparticle Composites

Development of Ultra-Thin Lens 100 Times Thinner Than a Human Hair

[Asia Economy Reporter Junho Hwang] A domestic research team has succeeded in developing an ultrathin lens that is 10,000 times thinner than conventional refractive lenses. This technology is expected to contribute to drastically reducing the size of smartphone cameras and aid in the development of various ultra-compact cameras such as infrared endoscopes, CCTV, and night vision devices. The research team led by Professor Junseok Noh of the Department of Mechanical Engineering and Chemical Engineering at Pohang University of Science and Technology, in collaboration with Professor Heon Lee of Korea University and Master Seunghoon Han of Samsung Electronics’ Advanced Institute of Technology, announced on the 30th that they developed a metamaterial-based lens with these characteristics. The research results were published on the 1st in the international academic journal ACS Nano.

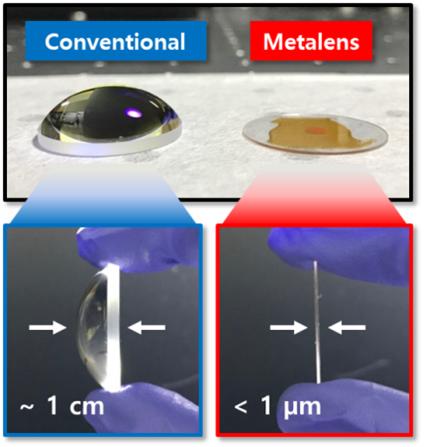

Lens Thickness, 1/100th of a Hair Strand

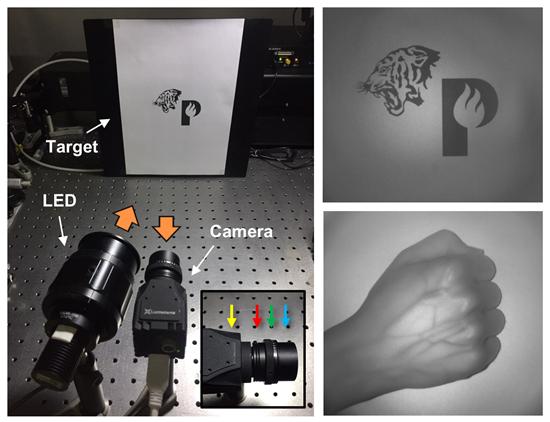

The lens developed by the research team has similar performance to conventional refractive lenses but is 10,000 times thinner. Compared to a hair strand, it is about 1/100th the thickness. The team successfully combined this lens with an actual optical system for imaging, verifying its practical applicability.

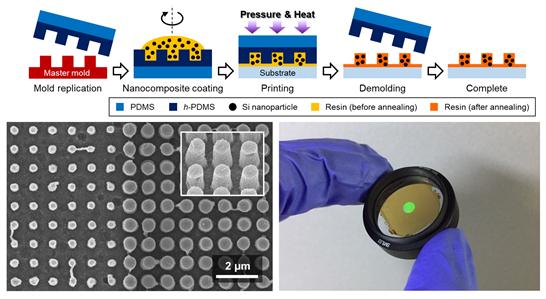

Originally, the research team studied metamaterial lenses to break the limit of refractive lenses that could not be made any smaller. However, considering the costs involved in metamaterial fabrication, they judged it economically unfeasible. Therefore, they turned their attention to a nanocomposite material that has optical properties suitable for metamaterial implementation and can be freely molded. They developed a material by mixing nanoparticles into a photosensitive resin that is liquid under normal conditions but hardens into plastic when exposed to light. The optical properties can be controlled by the type and concentration of nanoparticles, and the material is also cost-effective. Notably, the team developed a technology to print this material in one go. Compared to conventional electron beam lithography, the lens can be produced at speeds more than 100 times faster. Additionally, lenses can be made on curved substrates or flexible substrates. It is expected that lenses suitable for flexible smartphones or wearable devices can be developed in the future.

Thickness of Various Camera Lenses Can Also Be Reduced

Professor Junseok Noh explained, "The ultrathin metalens realized in this study is 10,000 times thinner than conventional infrared refractive lenses with the same optical properties, so it can solve various problems caused by large and heavy refractive lenses. We expect it to be applicable in various fields such as infrared endoscopes, CCTV, and night vision devices in the future."

Meanwhile, lenses that gather light are essential components in the latest electronic and optical devices such as smartphones and DSLR cameras. However, conventional refractive lenses are large and heavy, and their performance deteriorates as their size decreases. Therefore, smartphone cameras use compound lenses composed of 8 to 9 refractive lenses to reduce image distortion. However, since it is difficult to reduce the thickness of compound lenses, the so-called 'katuktu (camera protrusion)' problem occurs, where the camera protrudes from the back of the smartphone.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.