Storing CO2 in Steel Waste

Utilizing in Cement and Concrete

Using Organic Acids from Biomass Waste

Proposing Resource-Circulating High-Efficiency Carbon Mineralization

[Asia Economy Reporter Junho Hwang] A technology has been developed that combines volatile organic acid compounds and carbon dioxide produced from biochemical waste such as food waste and seawater/marine waste to create construction materials like cement. This technology enables the production of construction materials at a low cost while reducing carbon dioxide emissions.

The research team led by Professor Youngjun Park of the Department of Earth Environmental Engineering at Gwangju Institute of Science and Technology, in collaboration with Professor Ahhyung Park’s team at Columbia University, recently introduced a high-efficiency resource-circulating carbon mineralization process in the international chemistry journal (ACS Sustainable Chemistry & Engineering) on the 29th.

The team proposed a cost-effective method for carbon mineralization. Carbon mineralization refers to extracting alkali metals contained in natural minerals or solid industrial waste and reacting them with carbon dioxide to produce solid carbonates such as calcium carbonate and magnesium carbonate. These carbonates can be used as various forms of construction materials, including cement, concrete, and aggregates. However, the commonly used inorganic acids in this process face challenges in securing economic feasibility due to high solvent costs, low extraction efficiency, and difficulties in post-processing.

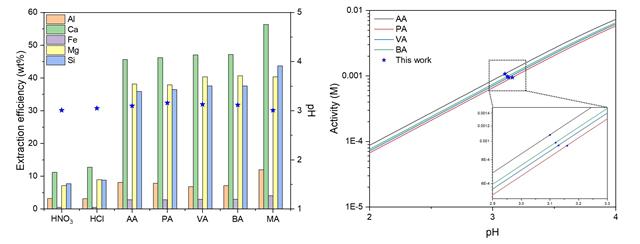

The researchers replaced these inorganic acids with a mixture of organic acids generated from biomass waste (such as food waste, sewage waste, and marine waste). Specifically, they utilized volatile organic acids to extract alkali metals from steelmaking slag (waste discharged during the steel manufacturing process). The team explained that the extraction performance was higher than before and that rare earth metals could also be selectively recovered.

First author of the paper, Researcher Sujin Hong, stated, "By applying this technology, it is possible to effectively reduce carbon dioxide generated in industry while converting large amounts of waste into eco-friendly construction materials (cement, concrete, aggregates, etc.), thereby improving the economic feasibility of the carbon mineralization process." She added, "In follow-up studies, we expect to contribute to the 2050 carbon-neutral resource-circulating economy through the development of useful resources based on carbon mineralization technology."

Effect of Solvent Type and Ligand on Metal Extraction Efficiency in Steelmaking Slag (Left) Metal extraction efficiency in the presence of inorganic or organic acids.

Effect of Solvent Type and Ligand on Metal Extraction Efficiency in Steelmaking Slag (Left) Metal extraction efficiency in the presence of inorganic or organic acids.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)