Jun Engineering Co., Ltd. and Mirae General Technology Co., Ltd. Greatly Improve Shipbuilding and Offshore Design Productivity

In line with the 4th Industrial Revolution, many small and medium-sized enterprises (SMEs) in the shipbuilding and marine ICT sector are accelerating the development of new software convergence services. Among them, Jun Engineering Co., Ltd.'s "Automatic Cable Measurement Program for Small and Medium-sized Shipbuilding" and Mirae General Technology Co., Ltd.'s "Rule-based Shipbuilding and Marine Outfitting Piping Design Verification System" have attracted industry attention by significantly enhancing productivity and quality in the shipbuilding and marine design process.

In South Korea, most large shipbuilders use the 3D design software from the UK’s AVEVA to perform efficient cable design. In contrast, small and medium-sized shipbuilders continue to rely solely on manual cable design based on past experience due to the high introduction cost of about 100 million KRW and lack of specialized resources, resulting in repeated inefficient processes.

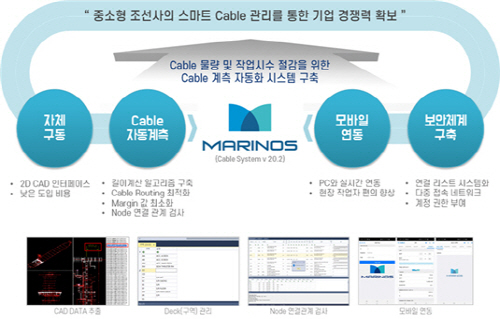

Reflecting this situation, Jun Engineering Co., Ltd. developed the "Automatic Cable Measurement Program Specialized for Small and Medium-sized Shipyards," which can be utilized at a low introduction cost to address the difficulties faced by small and medium-sized shipbuilders.

This program prevents human errors caused by manual work, improves unnecessary working time and costs, and produces reliable results based on accurate data.

The program is economically and industrially significant because it can be used in conjunction with CAD drawings without expensive design software. Its features include ▲ prevention of input errors through automation of manual input processes ▲ reduction of labor for Node Data input ▲ accuracy exceeding 98% compared to actual cable length measurements ▲ real-time PC-linked applications.

A representative from Jun Engineering Co., Ltd. stated, "Through this development, we achieved cost savings of about 90 million KRW per ship and annual savings of approximately 600 million KRW," adding, "Commercialization led to sales of about 200 million KRW, a 152% increase in total sales, and the creation of 8 new jobs."

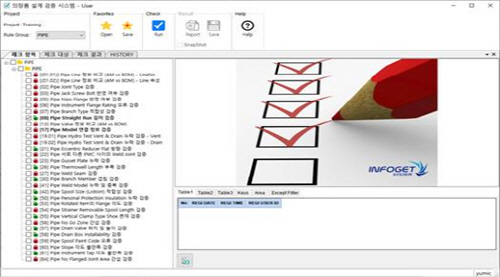

Meanwhile, Mirae General Technology Co., Ltd., which developed the "Rule-based Shipbuilding and Marine Outfitting Piping Design Verification System," has systematized the outfitting piping design system, which previously lacked a proper framework, presenting a new paradigm for domestic and international shipbuilding and marine design management.

The shipbuilding and marine industry, which proceeds based on the requirements of the shipowner (or company) commissioning the production, places great importance on the initial design. Errors in the basic design can cause fatal economic losses ranging from three to nine times during subsequent correction stages.

In reality, the shipbuilding and marine industry commonly uses 3D CAD systems for modeling, but in a desktop-based environment where workers verify all data one by one and generate 3D information and collaborate, the larger the project scale, the more human errors occur.

The "Rule-based Shipbuilding and Marine Outfitting Piping Design Verification System" defines rules through analysis of design error cases during production, installation, operation, and maintenance stages, reduces error rates through project-based rule management and periodic error notifications, verifies abnormalities in outfitting models, and improves design quality.

This verification system establishes a consistent production system through standardization of outfitting design information, reduces failure costs, and maximizes work efficiency at shipyard sites. Additionally, it is expected to become a new growth engine for the shipbuilding industry, where securing price competitiveness has become crucial due to low-price orders and the weak yen phenomenon.

A representative from Mirae General Technology Co., Ltd. stated, "As of November, the rule-based outfitting piping design verification system has been applied to the actual ships of two large domestic shipyards, and we plan to expand its application to more shipyards and design companies in the future."

Ulsan City and the Ulsan Information Industry Promotion Agency are actively supporting the commercialization of SMEs' software convergence eco-friendly autonomous ship technologies and products through the "SW Convergence Cluster 2.0 Project." A representative from the Ulsan Information Industry Promotion Agency said, "Commercialization support results are becoming visible, and we will continue to lead the activation of the software convergence ecosystem in the shipbuilding and marine industry and foster strong small and medium enterprises."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.