Follow-up Gas Turbine Efficiency 63%→65%... Development of 80MW-Class Medium Turbine by 2025

Early Commercialization Target for 300MW-Class Hydrogen Combustion Gas Turbine by 2040

Concurrent R&D on Core High-Temperature Material Parts such as Blades, Vanes, and Large Disks

Establishment of 'Innovation Cluster' in Bu-Ul-Gyeong... Research Power Plant Construction Promotion in 2021

President Moon Jae-in visited Doosan Heavy Industries in Changwon, Gyeongnam, a Green New Deal site, on the afternoon of the 17th. After signing the gas turbine blades at the gas turbine high-temperature parts factory, he applauded. To President Moon's right is Sung Yun-mo, Minister of Trade, Industry and Energy. (Photo by Yonhap News)

President Moon Jae-in visited Doosan Heavy Industries in Changwon, Gyeongnam, a Green New Deal site, on the afternoon of the 17th. After signing the gas turbine blades at the gas turbine high-temperature parts factory, he applauded. To President Moon's right is Sung Yun-mo, Minister of Trade, Industry and Energy. (Photo by Yonhap News)

[Asia Economy Reporter Moon Chaeseok] The government has unveiled the 'Gas Turbine Industry Competitiveness Enhancement Plan' to accelerate the localization of liquefied natural gas (LNG) gas turbine equipment. With the goal of becoming one of the world's top four gas turbine industries by 2030, it plans to promote demonstration projects for up to 15 gas turbines. This is expected to create a domestic market effect worth 4.4 trillion KRW.

On the 30th, the Ministry of Trade, Industry and Energy held a 'Meeting to Strengthen the Competitiveness of the Gas Turbine Industry' with industry-academia-research stakeholders at the auditorium of Korea Midland Power's Seoul Power Headquarters and announced this plan.

The meeting was attended by Minister Sung Yun-mo, Energy Resources Office Director Joo Young-jun, and other ministry officials, as well as Kim Jong-gap, CEO of Korea Electric Power Corporation; Park Hyung-gu, CEO of Korea Midland Power; Park Il-jun, CEO of Korea East-West Power; Jung Yeon-in, CEO of Doosan Heavy Industries & Construction; and Jung Ui-seok, CEO of Lost Wax.

Demonstration of 15 units by 2030... 4.4 trillion KRW market 'in full bloom'

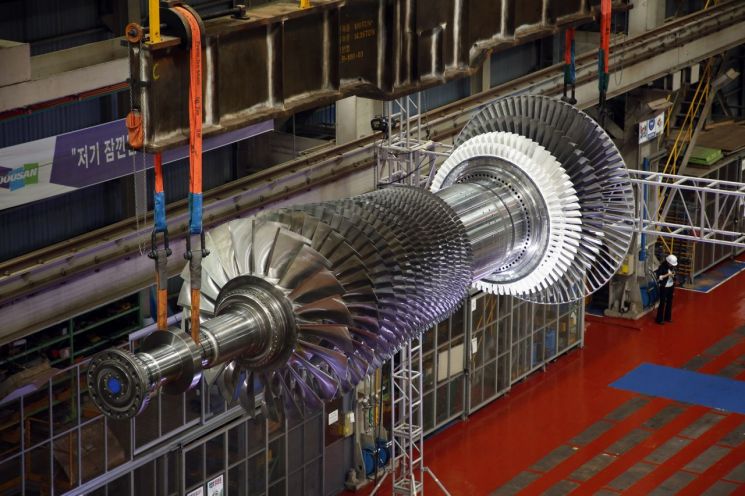

Installation view of the large gas turbine model for power generation (H-class, 270MW) developed by Doosan Heavy Industries & Construction in September last year. (Photo by Doosan Heavy Industries & Construction)

Installation view of the large gas turbine model for power generation (H-class, 270MW) developed by Doosan Heavy Industries & Construction in September last year. (Photo by Doosan Heavy Industries & Construction)

The enhancement plan was prepared nine months after the launch of the 'Korean Standard Gas Combined Cycle Development Commercialization Promotion Team' on February 13. The Ministry of Trade, Industry and Energy presented four major strategies for the enhancement plan: ▲Creating initial orders to establish an ecosystem foundation ▲Advancing technology development to achieve carbon neutrality goals ▲Enhancing competitiveness of high value-added core materials and components ▲Building regional industrial ecosystem infrastructure.

First, starting next year, a 'Korean Standard Combined Cycle Model' will be developed and demonstrated to standardize the performance and equipment specifications of combined cycle power plants. The plan is to create initial orders necessary to establish a stable gas turbine industry ecosystem.

To expand the localization of major components such as gas turbines, the ministry will expand phased demonstration projects for 15 units by 2030. The project will be carried out by encouraging power generation companies to voluntarily convert aging coal power plants to LNG power or by replacing aging LNG power plants that reach the end of their lifespan by 2030. Through this, the ministry expects to create a domestic gas turbine market worth 4.4 trillion KRW.

An official from the ministry said, "It is expected to contribute to establishing a domestic industrial ecosystem based on research and development (R&D) and demonstration projects founded on solidarity and cooperation between power generation companies as demanders and the gas turbine industry (such as Doosan Heavy Industries) as suppliers."

The ministry diagnosed that although LNG power generation plays a 'bridge power' role in reducing the intermittency risk (fluctuations in power generation due to weather and seasons) of new and renewable energy, the localization level of parts markets is low. The global market for power generation gas turbines is dominated by a few countries: the United States (GE, 58%), Germany (Siemens, 27%), Japan (MHPS, 11%), and Italy (Ansaldo, 4%), accounting for 96% of the total market. All 158 gas turbines installed in Korea's LNG combined cycle power plants rely on these four global companies.

Minister Sung Yun-mo emphasized, "In the energy transition process, LNG power generation needs to be expanded and maintained for the time being to maintain stable power supply and demand," adding, "Technological independence of gas turbines is an urgent task above all."

'65% Efficiency' Next-Generation Turbine Development... Commercialization of 300MW 'Hydrogen Turbine' by 2040

Large gas turbine model for power generation by Doosan Heavy Industries & Construction. (Photo by Doosan Heavy Industries & Construction)

Large gas turbine model for power generation by Doosan Heavy Industries & Construction. (Photo by Doosan Heavy Industries & Construction)

To increase the power generation efficiency of gas turbines from 60% to 65%, R&D for the next-generation model will begin next year. Currently, Doosan Heavy Industries' H-class (270MW) turbine is used. The turbine to be installed at the Gimpo combined heat and power plant of Korea Western Power, scheduled for completion in June 2023, will also be this H-class model. The next-generation model will be developed so that it can be immediately installed in LNG power plants.

R&D for 'ultra-high efficiency' gas turbines with combined efficiency of 65%+α will be pursued from 2024 to 2028. Additionally, R&D for an 80MW-class medium-sized gas turbine will be conducted concurrently from 2022 to 2025 to respond to the high variability of renewable energy.

Furthermore, development of combustors capable of hydrogen co-firing and full firing will begin this year. Through this, the ministry plans to consider demonstration of large gas turbine combined cycle power plants with hydrogen co-firing. In the first half of next year, a 'Hydrogen Gas Turbine Development Technology Roadmap' will be established. The goal is to commercialize a 300MW-class hydrogen full-firing gas turbine early by 2040.

Commercialization of 3 Core High-Temperature Components... Establishment of Southeast Region Cluster

To secure technology in the three core high-temperature components?blades, vanes, and large discs?joint R&D and commercialization will be promoted between power generation companies and small to medium-sized component manufacturers. Support for demonstration and commercialization of the supply chain council formed in May will begin in the second half of the year.

The key is to secure 1650℃-class high-temperature material component technology. By 2024, R&D will begin on 1650℃-class gas turbine precision casting materials and core materials and components for steam turbine high-temperature and lightweight technology. Through this, parts made by domestic small and medium-sized enterprises will enter the global value chain (GVC).

By 2023, the 'Power Unit Smart Manufacturing Center' will be established to provide reliability evaluation of gas turbine parts and support process and demonstration technologies. To operate LNG power generators commercially, parts must perform without failure for over 8,000 hours at temperatures above 1500℃.

Additionally, a 'Gas Turbine Industry Innovation Cluster' will be established in the southeast region, including Busan, Ulsan, and Gyeongnam, where 71% of the 341 domestic gas turbine companies are concentrated. Starting next year, the construction of a 'Gas Turbine Test Research Power Plant' centered in Changwon, Gyeongsangnam-do, will be promoted to establish performance verification infrastructure. Also, from next year, a 'Technology Support Project Group' will begin operation to resolve technical difficulties faced by small and medium-sized enterprises.

From next year, a 'Gas Turbine Innovation Growth Forum' will be operated among domestic and international industry-academia-research specialized institutions to expand technology exchange. The designation of an 'Energy Convergence Graduate School' and an 'Energy Innovation Research Center' will establish a system for training master's and doctoral level technical experts linked to industry and academia.

Minister Sung said, "If the domestic gas turbine industry ecosystem is well established through solidarity and cooperation among industry, academia, and research, it will become a strong stepping stone for the mid- to long-term energy transition to hydrogen power generation and the 2050 carbon-neutral society and economy."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.