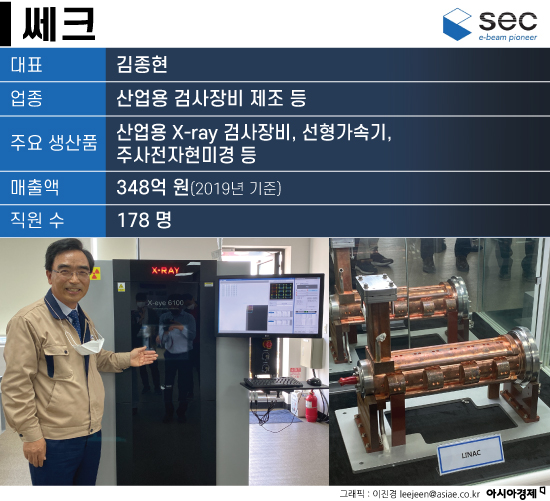

Sek, Korea's No.1 Industrial X-ray Inspection Equipment Company

Certified Small and Strong Materials Parts Company & Inno-Biz, Instantly Detecting Defects in Automobiles and Mobile Phones with X-ray Technology

Developed Linear Accelerator for Cargo Containers and Aircraft Engine Inspection

"Building a 100-Year Company Surviving Through Technology"

Kim Jong-hyun, CEO of Sec, is explaining the company's industrial X-ray inspection equipment. Sec is the only company in Korea that produces industrial X-ray tubes using electron beam technology, having secured the core technology. Photo by Kim Hee-yoon

Kim Jong-hyun, CEO of Sec, is explaining the company's industrial X-ray inspection equipment. Sec is the only company in Korea that produces industrial X-ray tubes using electron beam technology, having secured the core technology. Photo by Kim Hee-yoon

[Asia Economy Reporter Kim Heeyoon] “Our goal is to reliably detect defects in electronic components used in domestic industries such as semiconductors and batteries. As components become increasingly miniaturized and sophisticated, industrial X-ray equipment will become a necessity rather than a choice.”

Fires or explosions caused by defective components have highlighted the importance of thorough inspections for electronic component manufacturers. SecK, the leading company in the domestic market for industrial X-ray inspection equipment designed to detect minute soldering defects and tiny circuit faults, is a strong small and medium enterprise that produces inspection equipment and scanning electron microscopes based on the localization of X-ray generating tube technology.

On the 29th, at SecK’s headquarters in Gwonseon-gu, Suwon, Gyeonggi Province, CEO Kim Jonghyun stated, “Through electron beam technology that surpasses the limits of optical technology, we want to contribute to drastically reducing the defect rate of components in domestic electronics companies.”

CEO Kim, who was in charge of mechanical design at Samsung Electronics, founded SecK in 1991 after leaving the company. While excelling as a specialist in automation equipment, he predicted in the 2000s that existing optical technology would struggle to inspect ultra-small products as electronic components became more miniaturized and precise. Inspired by this, SecK began developing electron beam-based X-ray inspection equipment and succeeded in creating technology capable of detecting tiny defects as small as 20 micrometers within 0.3 seconds. The principle involves generating X-rays by colliding an electron beam with a specific object and using these rays to inspect the interior of products. CEO Kim explained that the technology allows high-resolution image output and high-speed video capture, enabling rapid detection of minute defects inside electronic components.

A SECK official observing the surface of a material using a scanning electron microscope that utilizes electron beam technology. The surface structure and composition of the material are analyzed and provided.

A SECK official observing the surface of a material using a scanning electron microscope that utilizes electron beam technology. The surface structure and composition of the material are analyzed and provided.

“Contributing to Lowering Defect Rates in Domestic Electronic Components through X-ray Inspection Technology”

The X-ray generating tube, a core component of the inspection equipment developed by SecK, was patented in 2006 as the first domestic technology. In addition, SecK recorded sales of 34.8 billion KRW in 2019 through the production of products utilizing electron beam technology, such as scanning electron microscopes for observing and measuring material surfaces and linear accelerators capable of 3D inspections.

If X-ray inspection equipment accounts for 65% of annual sales as the main device, linear accelerators and inspection equipment for electric vehicle batteries are future growth areas that SecK is focusing on. The linear accelerator, commercialized in 2015, is a non-destructive inspection device that analyzes the interior of products by accelerating electron beams at levels between 1 and 15 MeV (million electron volts). It enables large-scale inspections of cargo containers, aircraft engines, and defense equipment. CEO Kim said, “We have drastically lowered the price of container security scanners for ports using linear accelerators compared to existing foreign devices, securing price competitiveness. We are currently developing the localization of the key component magnetron, which has been fully imported, aiming to complete it by the first half of next year.”

Seck, which developed X-ray inspection equipment, scanning electron microscopes, and linear accelerators, has started developing inspection equipment for electric vehicle batteries, preparing for future industries. The photo shows a Seck official inspecting a circuit board. Photo by Kim Heeyoon

Seck, which developed X-ray inspection equipment, scanning electron microscopes, and linear accelerators, has started developing inspection equipment for electric vehicle batteries, preparing for future industries. The photo shows a Seck official inspecting a circuit board. Photo by Kim Heeyoon

Regarding the secondary battery inspection equipment currently under development, CEO Kim emphasized, “With the growth of the electric vehicle market, the secondary battery market is also expected to grow more than tenfold within ten years, so demand for 3D inspection equipment will surge. Since fires and explosions caused by component issues in mobile phones and automobiles are frequent, developing inspection equipment will significantly reduce defect rates in electric vehicles as well.”

SecK holds a total of 69 patents, including for the X-ray generating tube, and among its 178 employees, 74 are technical researchers. Last year, it was recognized for its technological capabilities by being selected as one of the ‘100 Small and Medium Enterprises in Materials, Parts, and Equipment’ by the Ministry of SMEs and Startups. CEO Kim, a professional technician who won a gold medal at the 1983 International Skills Olympics and was awarded the Order of Industrial Service Merit, said, “Our goal is to build a 100-year company by developing cancer treatment devices and autonomous driving electronic components based on excellent technology. Although we slowed down this year due to the COVID-19 impact, we plan to increase sales to 80 billion KRW next year through new business ventures.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.