Gold Coating on Graphite Surface

Controlling Crack Depth and Direction during Graphene Exfoliation

[Asia Economy Reporter Junho Hwang] A peeling method that can detach graphene, known as the "dream material" used in rollable TVs and flexible smartphones, in desired sizes and layers without defects has been developed. This method allows control over the area, number of layers, and yield of graphene, which is expected to accelerate the industrial use of graphene.

Professor Jaehyun Lee of Ajou University, Professor Seokgyun Son of Mokpo National University, and Executive Director Seongho Jo of Samsung Display announced on the 30th that they have developed this peeling method through joint research, and the related paper was recently published in the international academic journal Science Advances.

Dream Material 'Graphene' Development of a Large-Area Graphene Peeling Method with Controlled Number of Layers

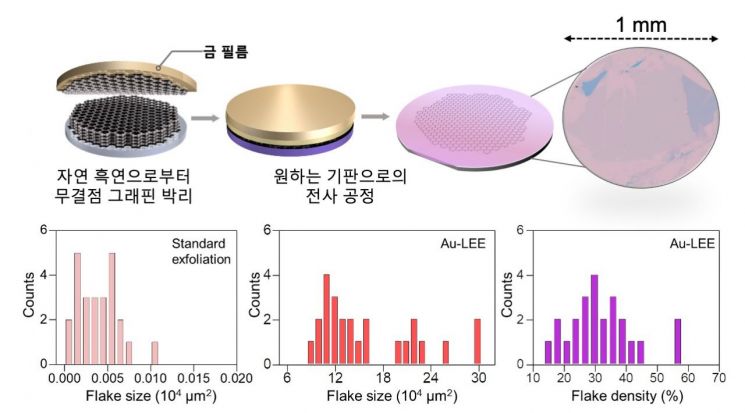

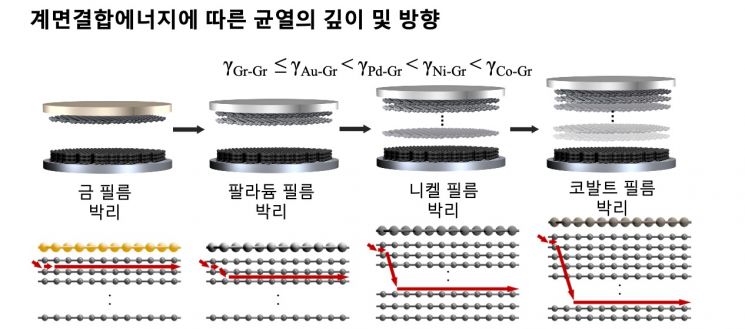

The research team developed a method of coating the graphite surface with gold, which bonds to the graphite surface at a level similar to the interlayer bonding force of graphene, and then peeling off the graphene with tape. When graphene is peeled off in this way, cracks propagate parallel to the surface, allowing only single-layer graphene to be separated.

The team also confirmed that when coating with palladium, nickel, or cobalt, which bond better with graphite than gold, and peeling with tape, the cracks become deeper, resulting in graphene with a greater number of layers.

The research team reported that using this method, they obtained graphene ranging from single layers at nanometer-scale areas to bilayers and up to 40 layers. This is about 4200 times larger in area for single-layer graphene compared to existing peeling methods. Additionally, the density of single-layer graphene per unit area increased by up to approximately 6000 times, securing a high yield.

Securing Defect-Free Graphene... The Foundation for Industrial Applications

Professor Lee Jaehyun of Ajou University (from the left), Professor Son Seokgyun of Mokpo National University, Executive Director Cho Seongho of Samsung Display, Moon Jiyoon, integrated master's and doctoral course student at Ajou University, and Dr. Kim Minsu of the University of Manchester

Professor Lee Jaehyun of Ajou University (from the left), Professor Son Seokgyun of Mokpo National University, Executive Director Cho Seongho of Samsung Display, Moon Jiyoon, integrated master's and doctoral course student at Ajou University, and Dr. Kim Minsu of the University of Manchester

The research team explained that this study enables obtaining graphene with desired area and number of layers. Previously, graphene was obtained by attaching and peeling specific tapes on graphite, making it difficult to control the area and number of layers.

The team stated, "We expect to present a new alternative for securing defect-free graphene, which is one of the obstacles to the industrial application of graphene."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.