Interview with Yoo Young-sun, President of the Korea Bio-Material Packaging Association (Professor, Department of Biotechnology, Catholic University)

"Environmental Protection and Plastic Waste Solutions Possible with Excellent Recyclable and Biodegradable Bioplastics"

Yu Young-sun, President of the Korea Bio-Material Packaging Association and Professor of Biotechnology at Catholic University, emphasized that the government must intervene in the issue of plastic waste disposal following the ban on plastic waste exports under the Basel Convention adopted last year. Photo by Kim Hee-yoon

Yu Young-sun, President of the Korea Bio-Material Packaging Association and Professor of Biotechnology at Catholic University, emphasized that the government must intervene in the issue of plastic waste disposal following the ban on plastic waste exports under the Basel Convention adopted last year. Photo by Kim Hee-yoon

[Asia Economy Reporter Kim Heeyoon] "Recycling and biodegradability will become the future direction of plastics, which are identified as the main culprits of environmental pollution."

The spread of the novel coronavirus infection (COVID-19) has driven the entire nation's plastic usage to its peak. With the prolonged non-face-to-face activities, consumption of home meal replacements (HMR) and delivery food has increased, causing a surge in plastic usage. However, due to the drop in international oil prices, the cost of producing new plastic has become cheaper than recycling waste plastic, turning waste plastic into a burden. According to statistics from the Ministry of Environment, the average daily generation of plastic waste in the first half of this year reached 850 tons, showing an increase of about 16% compared to the same period last year (732 tons). As the accumulation of waste plastic disposal becomes an environmental issue, attention is focusing on bioplastics for resource circulation.

"With the fall in international oil prices, demand for recycled plastic has decreased to the point where domestic processing of waste plastic is impossible. It is time for the government to play a role in addressing these issues." Yoo Young-sun, president of the Korea Bio-material Packaging Association (and professor of biotechnology at Catholic University), emphasized that the government must intervene in the waste plastic disposal problem following the adoption of the Basel Convention last year, which banned the export of plastic waste. During August and September, when social distancing was raised from level 2 to 2.5, plastic usage surged rapidly, causing widespread refusal to collect waste plastic. Some have expressed concerns that the waste crisis from two years ago might recur. Fortunately, through consultations between local governments and companies, a crisis was averted, but the waste plastic problem due to the prolonged COVID-19 situation could resurface at any time.

‘Bioplastics’ with Excellent Recycling and Biodegradability

The Korea Bio-material Packaging Association leads the eco-friendly packaging market through products made from carbon-neutral biomass for the environment. President Yoo explains that bioplastics with excellent recycling and biodegradability can solve environmental protection and waste plastic problems. Yoo said, "In the global packaging market, the eco-friendly premium packaging sector based on bioplastics is growing mainly in North America and Europe, but in developing countries, mid- to low-priced petroleum-based plastic packaging is mass-produced and traded due to price advantages."

What are the advantages of bioplastics? Yoo said, "Bioplastics made from natural carbon-neutral biomass are easier to biodegrade than general plastics, resulting in carbon dioxide reduction and prevention of global warming. Bioplastics using plant by-products such as soybean hulls and corn husks reduce the use of petroleum-based plastics, thereby decreasing environmental pollution caused by waste landfill," he added.

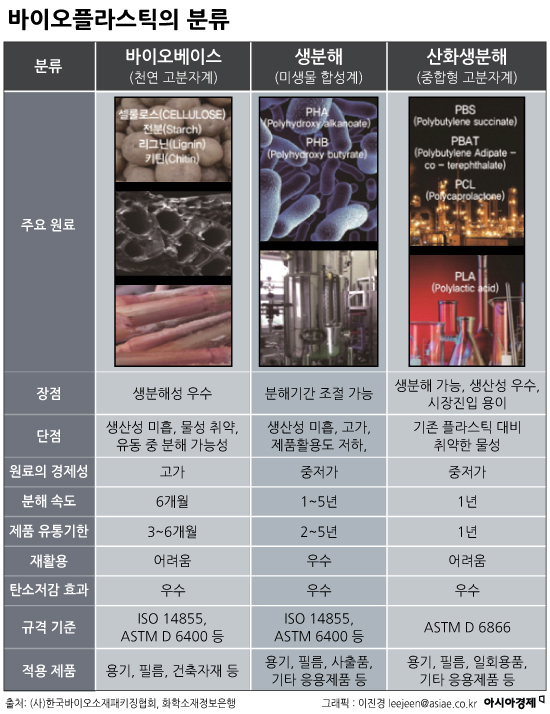

In fact, bioplastics are rapidly growing as an eco-friendly plastic that replaces petroleum-based plastics. The global market research firm Progressive Market predicted the global bioplastics market to grow from $17 billion in 2017 to $40.9 billion in 2022. Yoo explained, "Bioplastics can be divided into three types: biodegradable, oxo-biodegradable, and natural (bio-based). Among these, the market is expanding mainly around natural (bio-based) plastics with excellent physical properties. Korea has the world's top-level technology in manufacturing bio-based plastics."

After recycling collection companies announced they would stop collecting vinyl and Styrofoam, PET bottles left by residents have piled up at a garbage collection site in an apartment complex in Yongsan-gu, Seoul. Photo by Yonhap News

After recycling collection companies announced they would stop collecting vinyl and Styrofoam, PET bottles left by residents have piled up at a garbage collection site in an apartment complex in Yongsan-gu, Seoul. Photo by Yonhap News

"Government Budget Support Needed Rather Than Passing High Manufacturing Costs of Bioplastics onto Companies"

However, it is difficult to find bioplastics among plastic products in our daily lives. Assuming the cost of general plastic is 100 won, the manufacturing cost of bioplastics is about 300 to 600 won, making it expensive. Yoo points out the need for government policy intervention such as cost support. He said, "Whether biodegradable or natural, replacing petroleum-based plastics with bioplastics inevitably raises prices. If this cost is passed on to companies like the current recycling fees, product prices will increase. To protect the environment, it is necessary for the government to share the burden by supporting bioplastic production with funds collected as quasi-taxes, rather than shifting social costs onto companies."

According to the Korea Institute for Advancement of Technology, the domestic bioplastics market is about 40,000 tons, accounting for 0.5% of the domestic plastic market and about 1-2% of the global bioplastics market. Yoo said, "From a long-term perspective, the bioplastics market will move toward recycling rather than biodegradability. Although the application of eco-friendly bio-products is delayed due to various domestic regulations and lack of standards, as consumer awareness of the environment improves, if policy agreements between companies and the government are reached, it is expected that not only the domestic market size will be secured but also the localization and export of bioplastic materials and various market expansions will be possible."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.