Application of Zigzag Stacking Method

Expansion of 4 Lines at Hungary Factory

Parallel Use with Winding Manufacturing Method

Same Principle as SK Innovation's Method

Differences in Size, Material, and Order

No Patent Infringement Issues

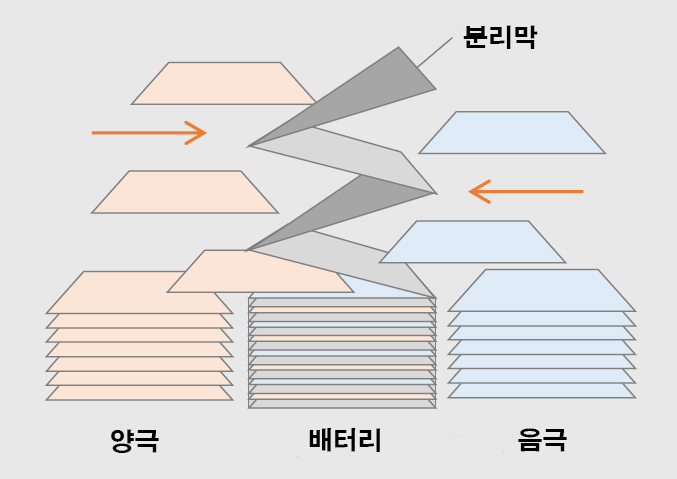

[Asia Economy Reporter Park Soyeon] Samsung SDI is making a significant change to its electric vehicle battery manufacturing method. Samsung SDI has been manufacturing batteries using the 'winding' method, which rolls the materials like a toilet paper roll, but recently switched to the 'zigzag stacking' method, where separators are stacked in a zigzag pattern with cathode and anode materials placed between each layer. This method is similar to the battery manufacturing process currently used by SK Innovation.

According to industry sources on the 22nd, Samsung SDI has begun expanding four new lines at its battery factory in G?d, Hungary, applying the zigzag stacking method. While four lines are currently operational at the Hungary factory, four additional lines will be constructed using the new method instead of the existing one. A Samsung SDI official explained, "Since battery manufacturing methods are not standardized, we plan to operate both the winding and zigzag stacking methods in parallel. For SDI, this is a new experiment, and due to the needs of automakers, we decided to apply the new method."

Currently, the battery cell manufacturing methods of domestic battery companies can be broadly divided into three types: Samsung SDI's winding method, LG Chem's stacking and folding method, and SK Innovation's zigzag stacking method.

The winding method involves rolling a large single cell into a cylindrical or prismatic case to make the battery. This was mainly used in the early stages of battery production. The cathode, anode, and separator materials of the secondary battery are rolled up and inserted into a cylinder to form a cylindrical battery or into a prismatic case to form a prismatic battery.

The stacking method, as the name suggests, involves stacking. Cathode, separator, and anode materials are neatly stacked and packaged. LG Chem and SK Innovation use this stacking method, but their ways of stacking separators differ slightly.

LG Chem's stacking and folding method cuts the separator and battery materials to a fixed length, stacks them, and folds the ends. SK Innovation's zigzag stacking method stacks a long separator in a zigzag pattern without cutting it, placing anode and cathode materials alternately between the layers. Samsung's existing winding method rolls the cathode and anode at the corners, which subjects them to strong pressure, but with the zigzag stacking method, the cathode and anode are not folded; only the separator is folded, improving durability.

With the recent decision to additionally adopt the zigzag stacking method, Samsung SDI is said to have thoroughly reviewed patent rights and other issues despite it being a general technology. The battery industry interprets this change as a response to the global attention on SK Innovation's battery method following electric vehicle fires that have impacted the global automotive industry. Among major battery companies, SK Innovation is the only one that has never experienced a single fire incident. Among global automakers, Ford in the U.S., Daimler in Germany, and Hyundai-Kia in Korea use SK Innovation's batteries.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.