Development of High-Performance and Durable Catalysts for Hydrogen Fuel Cell Vehicles

World's First 'Intermetallic Compound 3D Nanoframe' Catalyst

[Asia Economy Reporter Junho Hwang] A metal intermetallic compound nanoframe catalyst for fuel cells used in hydrogen electric vehicles has been developed. It is expected to contribute to the popularization of hydrogen cars as it offers higher stability and price competitiveness compared to electrode catalysts used in existing fuel cells when utilized as a next-generation catalyst.

The research team led by Professor Joo Sang-hoon of the Department of Chemistry at Ulsan National Institute of Science and Technology announced on the 6th that they developed a 'platinum-copper nanoframe catalyst' by preventing nanometer-sized catalyst particles from agglomerating at high temperatures. The related research results were published last month in Nano Letters, an international journal in the field of nanotechnology.

Development of Three-Dimensional Nanostructured Intermetallic Compound Catalyst

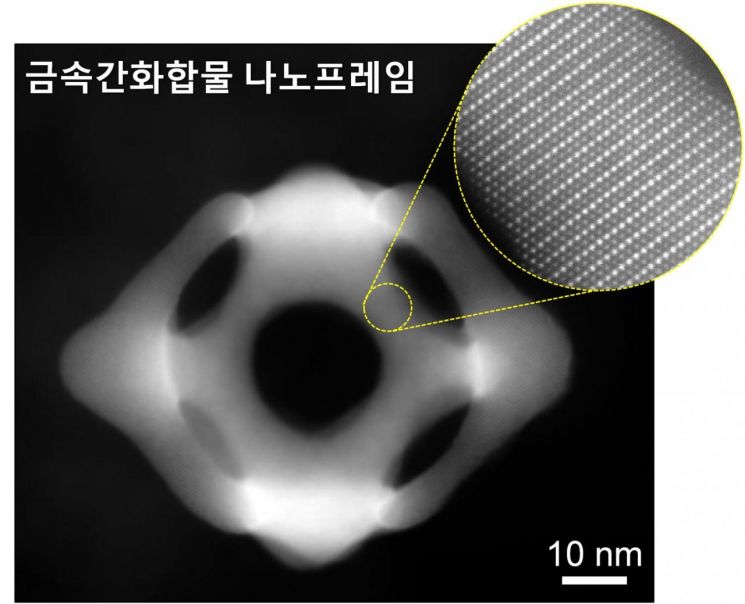

The catalyst developed by the research team has a hollow three-dimensional nanostructured frame. As a result, it has a large surface area where catalytic reactions can occur, enabling effective reactions.

This catalyst is composed of intermetallic compounds where atoms of the same type of metal are clustered. Therefore, it has fewer problems such as corrosion or dissolution of internal metal atoms compared to conventional catalysts, and it can reduce the amount of expensive platinum content.

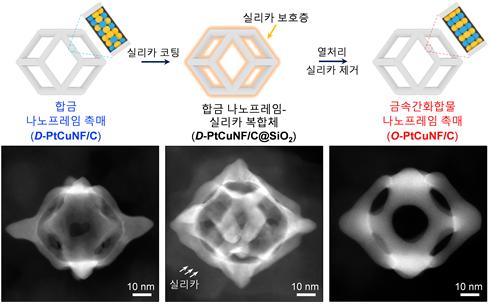

The research team solved the problem of particle agglomeration during the production of intermetallic compound catalysts by coating the surface of the nanoframe particles with a silica protective layer, and developed this catalyst.

Dr. Kim Ho-young, the first author of the paper, explained, "To create a regular atomic arrangement in intermetallic compound catalysts, the catalyst must be heated at high temperatures above 500°C, but at this time, nanoframe catalyst particles tended to agglomerate. By coating the surface of the platinum-copper catalyst particles with a silica protective layer, we were able to create an intermetallic compound nanoframe catalyst with a large surface area."

Application to Synthesis of Nanocatalysts with Various Compositions

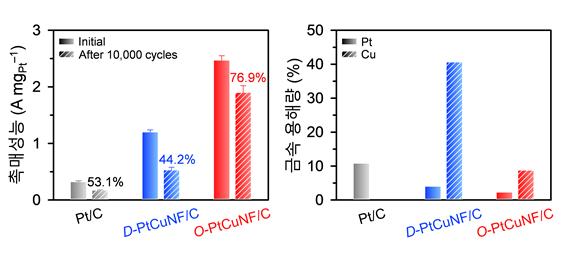

The intermetallic compound nanoframe catalyst developed by this method outperforms not only commercial platinum catalysts but also simple alloy nanoframe catalysts. Moreover, it showed the best performance even after stability tests (accelerated durability tests). In particular, it exhibited the least amount of metal species dissolved during the stability test.

Professor Joo Sang-hoon said, "The newly developed catalyst is the first case to combine a distinct polyhedral nanoframe structure with an intermetallic compound phase," and added, "The synthesis method used in this study is expected to be applicable to the synthesis of nanocatalysts with various compositions."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.