[Planning] Waste Crisis and Circular Resource Recycling in the Cement Industry

The kiln at the Ouvre factory in Belgium. There is no preheater. It still adheres to the method that Korea used until the early 1990s.

The kiln at the Ouvre factory in Belgium. There is no preheater. It still adheres to the method that Korea used until the early 1990s. [Photo by Korea Cement Association]

② Excessive Misunderstanding and Distrust: Domestic Cement Belittled as 'Garbage Cement'

[Asia Economy Reporter Kim Jong-hwa] At the end of 2014, domestic cement companies received several calls from China. At that time, some prospective residents of apartments planned in areas like Changwon and Wirye District contacted Chinese companies expressing interest in importing Chinese natural cement. Chinese companies, suspicious of this, reached out to Korean cement company contacts they knew to verify the credibility.

Upon investigation, it was found that a Korean environmental activist had given a lecture claiming, "Domestic cement is 'garbage cement' and poses risks such as sick building syndrome, atopic dermatitis, and radiation hazards, so using Chinese cement made only from natural raw materials is safer." This caused anxiety and fear, leading people to contact China to confirm import possibilities.

Chinese cement companies, upon hearing the story, said, "The Chinese cement industry also recycles circular resources (materials from waste that are environmentally harmless and economically viable) to address environmental issues and reduce energy costs, so this phenomenon is incomprehensible." They particularly questioned, "In China, even expired rat poison and confiscated and destroyed drugs are safely processed by being fed into cement kilns. Do Korean people consider this natural cement?"

Eventually, through active explanations and provision of materials by the Korea Cement Association and domestic companies, misunderstandings were resolved, and apartments in Changwon and Wirye District were completed using domestic cement. These apartments have had no problems to date. However, the excessive misunderstanding, distrust, and ignorance about cement by some citizens and environmental activists toward the domestic cement industry remain bitter.

In January, representatives from the domestic cement industry visited the 'Obourg' cement plant in Belgium and were surprised. The Obourg plant was completed 8 years before the March 1st Movement in 1919, boasting a history of over 100 years. More surprisingly, it still uses the older SP kiln method rather than the latest NSP kiln technology but produces cement stably by recycling circular resources.

At that time, a representative from the European Cement Association (CEMBUREAU) expressed puzzlement, saying, "Even the Obourg plant, which is over 100 years old, recycles circular resources to contribute to solving environmental problems. Why does the Korean cement industry, which has the latest production facilities and top-level technology, struggle to expand circular resource recycling?"

Japan calls cement produced through circular resource recycling 'Eco Cement' because it contributes to solving environmental problems. The Chinese cement company 'China United Cement Group Co., Ltd.' recycles an average of 12.9 million tons of waste annually over the past five years to produce cement. Their website states that they use 510,000 tons of hazardous waste, 80,000 tons of municipal waste, and 490,000 tons of sludge generated in the major city of Nanjing.

Recycling circular resources in the cement industry is already a global trend. In South Korea, it is criticized as 'garbage cement,' but worldwide it is recognized as 'eco-friendly cement.'

If a country cannot produce cement using recycled circular resources, it is due to a lack of technology. Cement is uniquely disparaged and criticized only in South Korea, but in Europe, Japan, and China, this is seen as an incomprehensible incident. Most countries recycle waste as circular resources through cement production facilities to reduce greenhouse gases and address environmental issues, but domestically, despite having excellent production facilities, South Korea lags behind in expanding circular resource recycling.

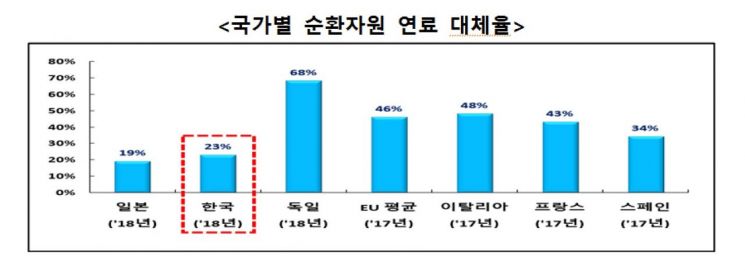

Status of Circular Resource Recycling in the Overseas Cement Industry. [Source=Korea Cement Association]

Status of Circular Resource Recycling in the Overseas Cement Industry. [Source=Korea Cement Association]

In 2018, the domestic cement industry's circular resource fuel substitution rate was 23%, while Europe recycled twice that amount at 46%. Particularly, the German cement industry substitutes 68% of its fuel. The Obourg plant in Belgium, boasting 109 years of history since its completion in 1911, has been recycling circular resources to replace fuel since 1984, reaching a substitution rate of 74%.

Before 1984, the Obourg plant faced severe difficulties due to explosive increases in energy costs, even facing pressure from shareholders to close the plant. However, since substituting fuel with circular resources from 1984, energy costs have been drastically reduced, and the plant has been recognized as a solution to environmental problems, escaping the threat of closure.

The activation of circular resource recycling through the cement industry in Western European countries, which advanced ahead of South Korea, is a natural phenomenon. The capitalist consumer culture of 'mass production-mass consumption-mass waste generation' inevitably brought environmental problems, which Europe, the U.S., and Japan experienced before South Korea.

They found solutions in the cement industry's manufacturing process. Amid the crisis where incineration and landfill have limits, the cement industry's manufacturing process, which uses circular resources as a heat source at an unimaginably high temperature of 2000℃, was a blessing for European countries. Japan even praised it as a 'vein industry' (an industry that safely recycles waste to protect the environment, like veins returning dirty blood to the heart to be renewed).

A Korea Cement Association official said, "The enormous social costs invested in solving environmental problems ultimately affect national competitiveness," adding, "Like Europe and Japan, although we have an effective environmental solution in the cement industry, if we lose the golden time due to some opposition viewing the cement industry with distorted perspectives, the gap with advanced countries will widen further," expressing regret.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![From Hostess to Organ Seller to High Society... The Grotesque Scam of a "Human Counterfeit" Shaking the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)