UNIST Professor Lee Jaesung's Team Develops Photocatalytic Electrode for Solar Hydrogen Production

Reduces Energy Consumption and Increases Hydrogen Output … Published in Nature Comm.

[Asia Economy Yeongnam Reporting Headquarters Reporter Kim Yong-woo] Will the era of producing clean fuel hydrogen using only water and sunlight come? Research that is bringing this new world closer has emerged.

A photocatalyst capable of producing clean hydrogen without using fossil fuels is being developed.

The research team led by Professor Lee Jae-sung of the Department of Energy Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) recently announced improved performance of a photocatalyst that can produce hydrogen using sunlight and water.

The photocatalyst, which constitutes the electrode of the ‘solar hydrogen production system,’ absorbs solar energy and produces hydrogen (H2) from water (H2O).

The newly developed catalyst is known to have dual functionality that lowers the energy consumption required for hydrogen production while simultaneously increasing the production amount, resulting in high hydrogen production efficiency.

Academia evaluates that Professor Lee’s team’s research results have set an important milestone in the commercialization research of solar hydrogen production systems.

Hydrogen, considered a clean fuel, is mostly obtained by reforming fossil fuels such as natural gas. However, the process of producing hydrogen from fossil fuels paradoxically emits carbon dioxide, which causes global warming, thus it is called ‘gray hydrogen.’

There is a method to produce ‘green hydrogen’ using infinite raw materials like water and renewable energy, but it still lacks price competitiveness and thus has limited practical value.

Therefore, a cheap catalyst that can reduce the energy consumed in production and increase hydrogen output was needed.

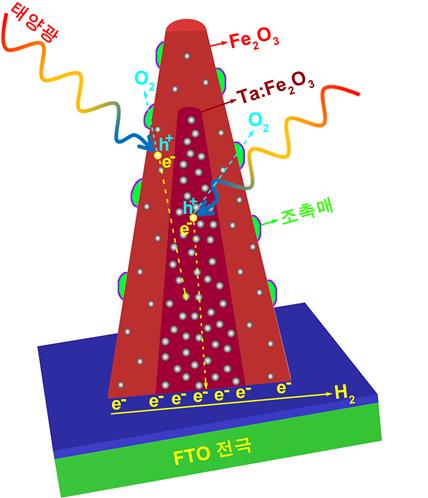

Professor Lee Jae-sung’s team secured efficiency by reducing energy consumption and increasing hydrogen production by creating iron oxide in a ‘core-shell’ dual structure.

The reaction onset voltage, which indicates energy consumption, dropped by 270 mV compared to general iron oxide electrodes, and the current density, an indicator of hydrogen production amount, increased by 66.8% compared to existing iron oxide catalysts. This overcomes the limitation of most previously developed catalysts that showed performance in only one of the two aspects.

The catalyst material used, iron oxide (Fe2O3), is the red substance seen in rusted iron. It is inexpensive and easy to obtain. It also absorbs a wide range of solar wavelengths.

However, due to internal charge (electron) transfer issues, the hydrogen production efficiency was not high when using this catalyst.

The research team developed a high-efficiency catalyst by creating a dual structure of iron oxide to improve internal charge transfer issues.

The structure consists of a tantalum (Ta)-doped iron oxide core surrounded by an undoped iron oxide shell.

It is a nanorod structure similar to a pencil. These rod particles were sintered like making ceramics to form an electrode composed of photocatalysts.

In the sintering reaction, a microwave absorber like graphite was used to enable sintering at high temperatures in a short time.

(From the front row left, counterclockwise) Professor Jaesung Lee, Research Professor Hemin Zhang, Professor Taeju Shin, Professor Hooyoung Jung, Researcher Woojin Byun.

(From the front row left, counterclockwise) Professor Jaesung Lee, Research Professor Hemin Zhang, Professor Taeju Shin, Professor Hooyoung Jung, Researcher Woojin Byun.

Professor Lee stated, “The goal is to achieve a hydrogen production efficiency of 10%, a turning point for commercialization, through additional research,” and concluded, “This newly developed catalyst brings us one step closer to that goal.”

Professor Lee Jae-sung is a leading scholar in the field of solar hydrogen production with over 20 years of research experience. His team is conducting demonstration research to apply this technology to ‘solar hydrogen vehicle charging stations’ within the next five years, supported by the Ministry of Science and ICT’s climate change response project budget.

This research involved UNIST Department of Energy Chemical Engineering Research Professor Hemin Zhang, UNIST Research Support Headquarters’ Jeong Hu-young and Shin Tae-joo professors, and Chinese Dalian Institute of Chemical Physics (DICP) researchers X. Wang, H. Han, and C. Li. It was published in the international academic journal Nature Communications on September 15.

The research was conducted through the Ministry of Science and ICT’s climate change response project and mid-career researcher support project.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.