Development of Silicone Solar Cell Separator with Added Water

Enhancing Performance and Reducing Cost

Increasing Commercialization Potential

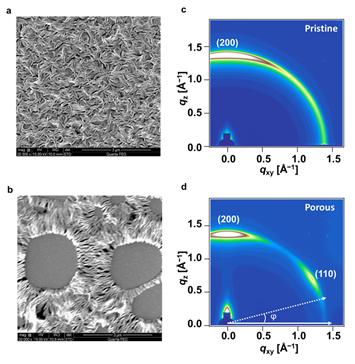

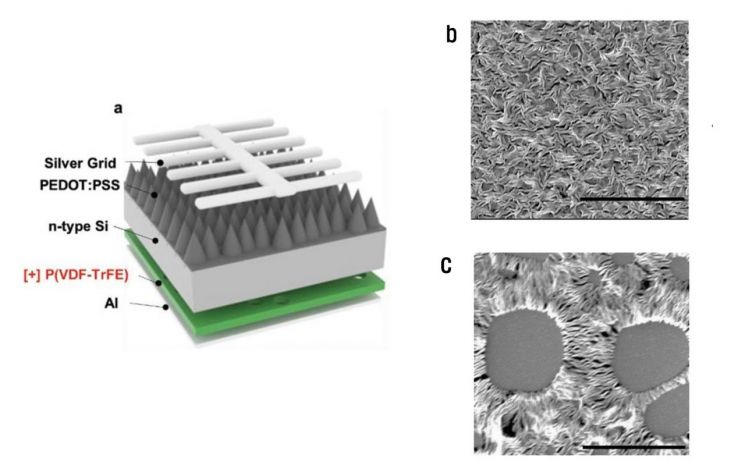

Structure of a solar cell equipped with a membrane containing added water (a) and the alignment structure of the organic thin film by water (b is before alignment, c is after alignment)

Structure of a solar cell equipped with a membrane containing added water (a) and the alignment structure of the organic thin film by water (b is before alignment, c is after alignment)

[Asia Economy Reporter Junho Hwang] A technology that improves the efficiency of silicon solar cells and reduces their cost using water has been developed.

Professor Kyungjin Choi's research team from the Department of Materials Science and Engineering at Ulsan National Institute of Science and Technology announced on the 16th that they have developed a technology that improves the performance of the 'rear passivation layer (rear electric field layer)' of silicon solar cells and simplifies the manufacturing process. The research paper was published on the 13th (local time) in the materials science journal Advanced Functional Materials.

Passivation Layer Made with Water

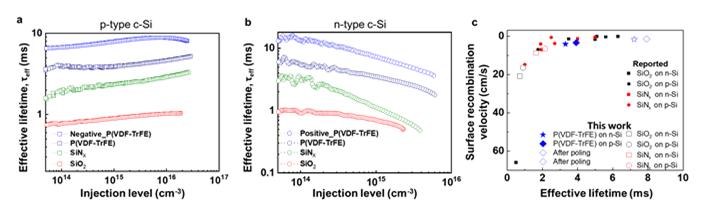

The research team implemented a passivation layer for solar cells by adding water. By adding a small amount of water to an organic ferroelectric thin film, they enhanced the efficiency of the passivation layer. When water is added to an organic thin film that does not mix with water like oil, organic particles in the form of fibers with lengths of several microns (μm, 10^-6) align densely and regularly. As the microstructure aligns, the force that attracts electrons and repels holes increases, improving the performance of the passivation layer.

Using the water-added passivation layer developed by the research team eliminates the need for expensive processes that drill holes in the passivation layer. Since the passivation layer is an electrically insulating material, holes must be created to provide pathways for electrons and holes. The newly developed passivation layer allows holes to be easily created by evaporating and removing the added water. This can reduce the cost of solar cells.

The passivation layer prevents recombination between photogenerated electrons and holes. The photoactive layer (such as silicon or perovskite) exposed to sunlight generates electrons and holes, and the passivation layer prevents these electrons (negative charge) and holes (positive charge) from recombining and disappearing. Since the amount of electricity produced by the cell is determined by the quantity of electrons and holes, an effective passivation layer that prevents their recombination is necessary to improve cell efficiency.

Ready for Commercialization

Corresponding author Professor Kyungjin Choi said, "By controlling the electrical properties (direction of the electric field) of the organic thin film (ferroelectric), this film can be used for both n-type and p-type silicon solar cells," adding, "This research also solved the chronic problem of temperature and humidity instability of organic material thin films (operable for 1000 hours), making commercialization prospects bright."

He continued, "This research expanded the rear electric field layer technology of silicon solar cells, which was limited to inorganic materials, to organic materials," and predicted, "Unlike inorganic thin-film solar cells that require expensive vacuum equipment, using organic thin films simplifies the process, enabling the production of competitively priced solar cells."

First author Researcher Seongbeom Kang explained, "We discovered the alignment phenomenon (increased crystallinity) of the microstructure inside the organic thin film and devised a manufacturing method for silicon solar cells using this."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.