Development of Adhesive That Sticks Well and Is Like Rubber Bands

Can Be Used in Rollable Displays and More

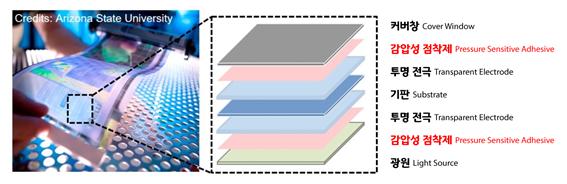

The appearance of a rollable display (Asia Economy DB, unrelated to the article).

The appearance of a rollable display (Asia Economy DB, unrelated to the article).

[Asia Economy Reporter Junho Hwang] An adhesive with both strong adhesion and elasticity has been developed. It is transparent and does not corrode metals, making it suitable for securing various components in display devices. The research team expects it to contribute to the development of rollable displays that can be carried folded and then unfolded.

A research team including Professor Dongwook Lee from the Department of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) and Professor Hakseon Kim from the Department of Electrical and Electronic Engineering announced on the 15th that they have developed an acrylic-based pressure-sensitive adhesive capable of immediate shape recovery like a rubber band. The research results were introduced last month in the Chemical Engineering Journal, an international journal in the field of chemical engineering.

Development of Adhesive with Strong Adhesion and Elasticity

The research team developed an adhesive with excellent adhesion (peel strength) and elasticity (immediate shape recovery ability). Pressure-sensitive adhesives are materials that adhere with just a slight pressing force. Generally, peel strength and elasticity of adhesives are inversely proportional, but the team applied a pre-deformation technique that involves pre-stretching the adhesive to achieve both strong adhesion and elasticity. The peel strength was found to be 65% higher than that of commercial Scotch tape. They also confirmed elasticity that immediately recovers deformation when stretched to 25% beyond its original length.

Professor Hakseon Kim said, "Consumers want large screens to view but small sizes to carry. Ultimately, the screen must be folded, rolled, or crumpled, so developing adhesives that can withstand external deformation is essential."

Applicable to Rollable Displays

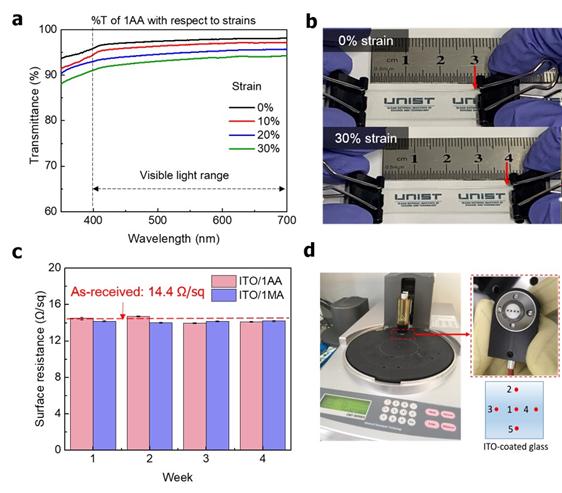

Evaluation table of display device compatibility for the developed adhesive. a represents transmittance evaluation according to strain change, b shows the actual transparency of the adhesive at 30% strain, c indicates the surface resistance value of the ITO substrate in contact with the adhesive under high temperature and humidity conditions, and d is a photo of the surface resistance measurement device.

Evaluation table of display device compatibility for the developed adhesive. a represents transmittance evaluation according to strain change, b shows the actual transparency of the adhesive at 30% strain, c indicates the surface resistance value of the ITO substrate in contact with the adhesive under high temperature and humidity conditions, and d is a photo of the surface resistance measurement device.

In particular, this adhesive showed high compatibility with display devices. Since metal electrodes are embedded inside the device, the adhesive must not corrode the metal. The research team attached the adhesive to ITO, the electrode material, and exposed it to a high-temperature and high-humidity environment for four weeks, but no corrosion (surface resistance increase) of the substrate occurred. This adhesive is also transparent, allowing light emitted from luminescent materials to pass through without obstruction.

Juhak Lee, a master's student in the Department of Energy and Chemical Engineering and the first author of the study, expressed expectations that "this research will play an important role in the advanced display field and the development and manufacturing of new pressure-sensitive adhesives."

Professor Dongwook Lee explained, "If we develop a process that easily applies the pre-deformation strategy and further improve adhesion, it will be possible to mass-produce adhesives usable in display devices."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["I'd Rather Live as a Glamorous Fake Than as a Poor Real Me"...A Grotesque Success Story Shaking the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)