Reader Material Technology and Microfabrication Application

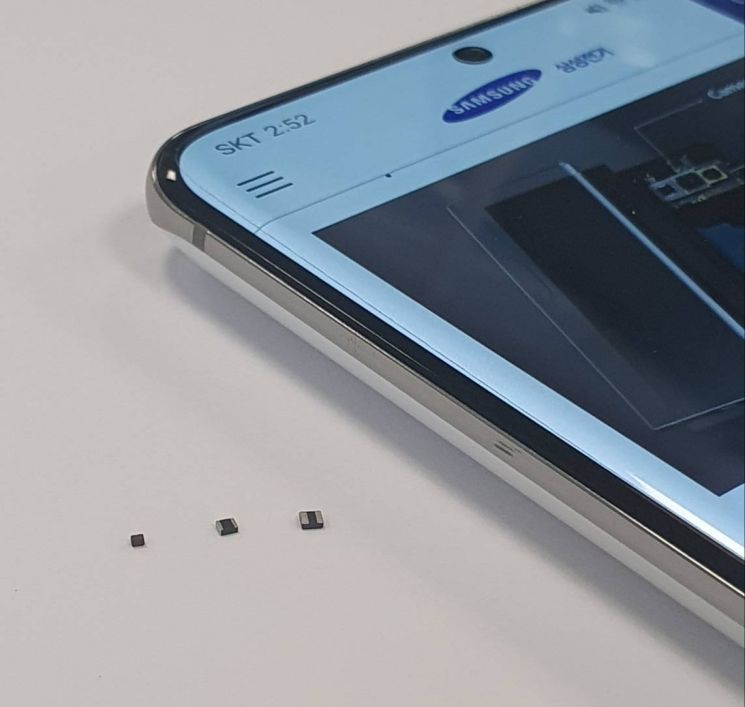

[Asia Economy Reporter Dongwoo Lee] Samsung Electro-Mechanics announced on the 13th that it has developed the world's smallest power inductor. The newly developed power inductor measures 0804 size (0.8 mm width, 0.4 mm length), significantly reducing the area compared to the previously smallest mobile product of 1210 size (1.2 mm width, 1.0 mm length), while maintaining an ultra-thin thickness of only 0.65 mm. Samsung Electro-Mechanics plans to supply this product to global mobile companies.

Power inductors are essential components required to stably supply power from the battery to semiconductors and are indispensable in smartphones, wearable devices, electric vehicles, and more. Recently, IT devices have become increasingly lightweight and compact, and with multifunctional and high-performance features such as 5G communication and multi-cameras, the number of components installed has increased, reducing internal component mounting space and driving demand for ultra-small products. Additionally, as component specifications improve, the power consumption increases, necessitating power inductors capable of withstanding high currents.

The performance of power inductors is generally determined by the magnetic material (a material possessing magnetism) used as raw material and the number of coils (copper wire) that can be wound inside. To enhance the performance of power inductors, it is necessary to improve the characteristics of the magnetic material and wind more coils within a limited space.

Samsung Electro-Mechanics applied material technology accumulated through MLCC and semiconductor substrate manufacturing processes to reduce the size by more than half compared to existing products and improve power loss. Unlike the conventional method of processing power inductors individually, Samsung Electro-Mechanics produces them at the substrate level to increase productivity and developed the product with a thinner thickness.

Samsung Electro-Mechanics independently developed raw materials applied with nano-scale ultra-fine powder and succeeded in implementing coils with fine spacing by applying photolithography (a manufacturing method that engraves circuits using light) used in semiconductor manufacturing.

Vice President Kangheon Heo, head of Samsung Electro-Mechanics Central Research Institute, said, “As electronic products become higher in performance and more functional, the size of internal components decreases, and differentiated technology is required to improve performance and capacity. Samsung Electro-Mechanics is the only company possessing material technology and microfabrication technology, enhancing product competitiveness through technological convergence.”

Samsung Electro-Mechanics has been developing and producing inductors since 1996 and is recognized for its industry-leading technology in miniaturization. The company plans to expand its product lineup and market share through ultra-differentiated technologies such as raw material development and ultra-fine fabrication processes.

Due to the high performance and multifunctionality of electronic devices, the activation of 5G communication, and the growth of the wearable device market, demand for ultra-small power inductors is expected to increase rapidly, with the number of components installed in electronic devices projected to grow by more than 20% annually.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.