⑩History of Korea's Cement Industry

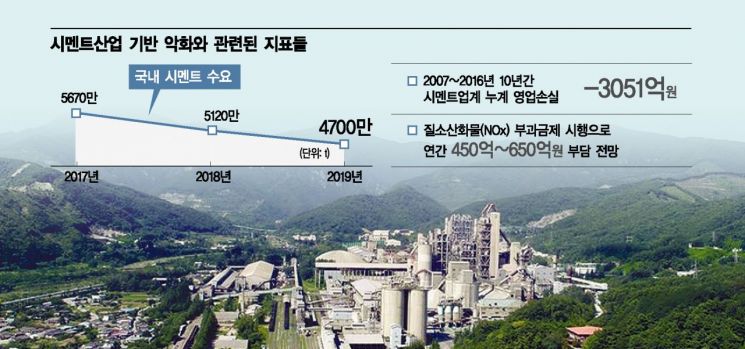

Panoramic view of Hanil Cement Danyang Plant. It is known as an eco-friendly cement factory.

Panoramic view of Hanil Cement Danyang Plant. It is known as an eco-friendly cement factory. [Photo by Hanil Cement]

[Asia Economy Reporter Kim Jong-hwa] Ssangyong Cement has succeeded in developing technology to utilize waste tire heat using cement kilns, positioning the cement industry as a problem solver for environmental issues.

Building on the success of fuel conversion of waste tires, the cement industry in advanced countries has addressed environmental problems such as increasing waste, confirming that the cement industry has become a "blessing to capitalism." The scope of recycling circular resources is expanding beyond auxiliary fuels like waste plastics to include by-products such as coal ash and slag.

In fact, long before the recycling of waste tires, since the 1980s, the cement industry has been substituting some raw materials such as clay and iron ore?excluding limestone, which accounts for about 90% of raw materials in cement manufacturing?with coal ash generated from burning bituminous coal in thermal power plants and slag produced during steelmaking in the steel industry.

In particular, coal ash replaces the natural raw material clay. In the 2000s, the rapid increase in power demand led to a surge in coal ash production. Power companies, struggling with landfill disposal and related environmental issues such as soil contamination, escaped crisis by supplying all coal ash to the cement industry for recycling as a clay substitute by-product.

Later, an ironic situation arose when coal ash supply for cement manufacturing decreased as it was sold as a mixed material for ready-mixed concrete production. What was once a pariah became a gem. Recently, collaboration between power companies and the cement industry has actively improved conditions for coal ash recycling.

Recycling circular resources in the cement industry, which reduces environmental burdens from mining development and cuts greenhouse gas emissions from fossil fuels, has already been recognized by related experts and academia. There are also opinions that the government should actively utilize the eco-friendly role of the cement industry to solve environmental problems.

On June 29, at the 1st Plastic Forum held at Seoul National University Hoam Faculty House, Professor Emeritus Kang Tae-jin of Seoul National University stated, "The current global plastic production volume is about 450 million tons, and if the current trend continues, it will reach a staggering 1.2 billion tons by 2050," emphasizing, "Just as the cement industry solved the social problem of waste tires over 20 years ago, the current issue of waste plastic disposal should also be resolved by using it as auxiliary fuel in cement manufacturing to address environmental problems."

Hong Soo-yeol, Director of the Resource Circulation Social Economy Research Institute, also said, "Due to the recent spread of COVID-19 and the rise of untact (contactless) phenomena, the use of single-person plastic containers has surged. To overcome the plastic waste crisis and climate crisis caused by this, all means must be mobilized," stressing, "One of the currently available infrastructures is cement production facilities. Due to the nature of production facilities that must operate at high temperatures for cement manufacturing, plastics can be safely processed, and by replacing fossil fuel bituminous coal, greenhouse gas emissions can also be reduced."

The cement industry holds the key to solving national environmental problems through recycling circular resources. If it was once the light of economic development, it has now been assigned a new mission as an eco-friendly industry that addresses the shadows of development. To make this possible, government policy direction, strong operational will, and a shift in public perception of the cement industry are necessary.

However, there is still a long way to go. Successful cases that should be recognized as eco-friendly industries are misunderstood as "waste cement," failing to overcome the wall of distrust.

An official from the Korea Cement Association said, "The domestic cement industry suffers from the stigma of 'waste cement.' Even advanced cement industries in Europe, Japan, and neighboring latecomers like China find this puzzling," adding, "Ultimately, the realization of a resource-circulating society depends on how quickly the cement industry can shed the negative perception of recycling circular resources."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.