Domestic Factories Nationwide Scheduled for Summer Vacation from 3rd to 7th Next Month

Line Construction Planned for New Starex During Vacation

Preparation Plans for Next-Generation Electric Vehicles and G80 Electric Vehicle Also Underway

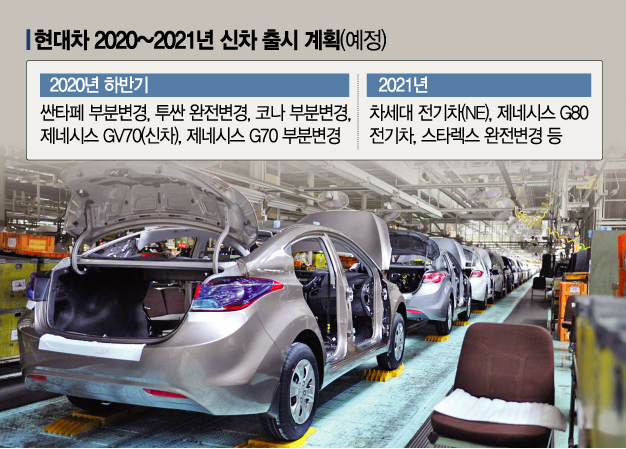

[Asia Economy Reporter Kim Ji-hee] Hyundai Motor Company will accelerate preparations for new vehicles by utilizing the summer vacation period in early next month. Although the first half of this year was a period of pause due to the impact of the novel coronavirus (COVID-19), the company is determined to rebound through new vehicles starting in the second half of the year.

According to industry sources on the 15th, Hyundai Motor plans to carry out construction work for mass production of the successor model to the Starex at Ulsan Plant 4 from August 1 to 14. They will shut down the body line and replace production equipment by adding one week to the summer vacation scheduled from August 3 to 7. However, the body line for the Palisade, which is produced mixed on the same plant, will operate without additional holidays to avoid production disruptions.

During this vacation period, Hyundai Motor plans to organize the lines not only for the successor model of the Starex van but also for the production of multiple new vehicles. As of now, 19 days before the summer vacation, construction work on lines at three locations in Ulsan?Plant 1, Plant 4, and Plant 5?has been confirmed. The company will actively utilize the periods before and after the vacation. First, from August 1 to 23, Plant 1 will undergo work to convert some lines into electric vehicle-exclusive lines. This plant will produce a new electric vehicle (development name NE). Additionally, Plant 5 will undergo line construction from July 28 to August 9 to produce models including the Genesis G80 electric vehicle. Most of these models are scheduled for release from the second half of this year to the first half of next year.

These models, which are entering full-scale launch preparations, are highly anticipated in the industry as they are directly linked to Hyundai Motor Group’s future vision. Hyundai’s next-generation electric vehicle 'NE' is the first mass-produced car based on an electric vehicle-exclusive platform (E-GMP), not a partial modification of an existing model. The G80 electric vehicle is the first eco-friendly model introduced by the Genesis brand. Since it combines the popular eco-friendly engine with the G80, the brand’s highest-volume model, expectations both inside and outside Hyundai Motor Group are considerable. Lastly, the successor model to the Starex, confirmed for construction, is a fully redesigned model released 14 years after its debut in 2007 and is expected to target emerging markets such as ASEAN.

In addition, Hyundai Motor is also likely to begin preparatory work for the production of derivative models of already released vehicles such as the Avante Hybrid during the summer vacation period at domestic plants. Not only the Ulsan plant but also other domestic plants such as Asan and Jeonju are reportedly actively considering line maintenance before and after the vacation.

This is not the first time Hyundai Motor has carried out line construction during a break period. However, it is considered rare for construction to be carried out on production lines for multiple models as it is this year. Last year, Hyundai conducted equipment construction during the summer vacation to enable joint production of the Palisade, which was previously produced only at Ulsan Plant 4, at Plant 2. In the first half of this year, when shutdowns due to COVID-19 were repeated, new vehicles such as the Genesis GV70 were prepared during downtime.

Having faced difficulties in domestic and overseas markets due to the COVID-19 situation this year, Hyundai Motor has recently rushed to prepare for new vehicle mass production while also implementing special extended work hours exceeding 52 hours per week to shorten delivery times for popular models. Since July 24, the Ulsan plant’s delivery center and rear-wheel 8-speed transmission production plant have been working an additional 8 and 10 hours, respectively. This strategy appears aimed at defending sales performance centered on popular models in the domestic market, which has been less affected by COVID-19, and securing momentum for a rebound through new vehicles in the future.

An industry official said, "Most of the models currently selling well domestically are new vehicles released within about six months, so it will be difficult for the finished car industry to delay new vehicle plans," adding, "In the long term, Hyundai Motor Group is treating the next 3 to 5 years as a period to realize its future strategy, so it is highly likely that they will maintain existing plans centered on symbolic models."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.