[Asia Economy Reporter Junho Hwang] Domestic researchers have secured a technology to manufacture transparent plastic films exhibiting a refractive index of 1.9 or higher through a single deposition reaction. This is expected to become a core technology that enables higher light refraction at thinner thicknesses in line with the miniaturization trend of smartphone cameras and other devices.

The research team led by Professor Seonggap Lim of the Department of Biological and Chemical Engineering at the Korea Advanced Institute of Science and Technology (KAIST), Professor Gukheon Cha of the Department of Chemical and Biomolecular Engineering at Seoul National University, and Professor Jiwoo Lim of Kyung Hee University announced on the 14th that they secured this technology through joint research and introduced it in the international academic journal Science Advances.

Development of Polymer with Refractive Index Above 1.9... World’s First

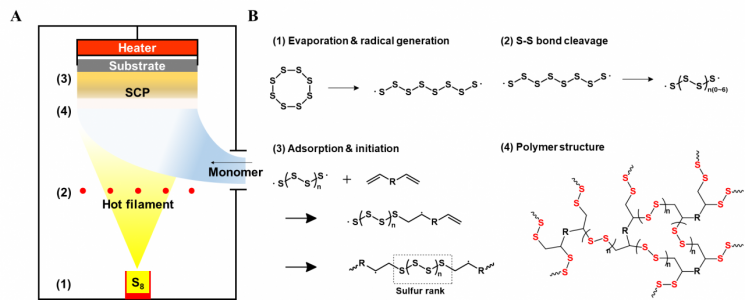

Schematic diagram of a method for copolymerizing gaseous sulfur to fabricate a high refractive index thin film.

Schematic diagram of a method for copolymerizing gaseous sulfur to fabricate a high refractive index thin film.

The research team realized a polymer with a refractive index above 1.9 for the first time in the world by utilizing sulfur. They applied a method of polymerizing gaseous sulfur, taking advantage of the fact that elemental sulfur easily sublimates, to create a high-refractive-index polymer. This method suppresses the formation of excessively long sulfur-sulfur chains and ensures excellent thermal stability even at high sulfur content. In particular, it is possible to obtain an amorphous polymer that is transparent across the entire visible light spectrum while having a high refractive index.

Polymer (plastic) materials are widely used in various fields such as plastic eyeglass lenses due to their excellent properties and ease of processing into various forms. However, among polymer materials developed so far, those with a refractive index exceeding 1.75 are extremely rare. Even if they exist, they require expensive raw materials and complex synthesis processes. Notably, most of the foundational technologies related to such materials are held by Japan.

Localization of Core Technology for High-Refractive-Index Polymers

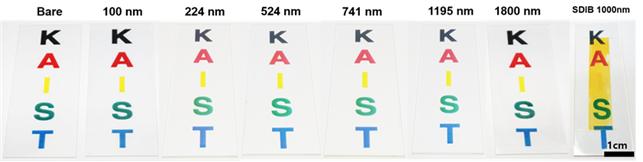

Photos of synthesized ultra-high refractive index polymers with varying thicknesses (7 from the left) and a photo of the conventional sulfur-based polymer (SDIB). Unlike the conventional sulfur polymer, which has a deep yellow color, the materials obtained in this study exhibit excellent transparency.

Photos of synthesized ultra-high refractive index polymers with varying thicknesses (7 from the left) and a photo of the conventional sulfur-based polymer (SDIB). Unlike the conventional sulfur polymer, which has a deep yellow color, the materials obtained in this study exhibit excellent transparency.

The technology developed by the research team is significant in that it achieved localization of the core technology for high-refractive-index plastic materials. It is also expected to be utilized in various fields. This technology can be widely applied in cutting-edge IT device sectors that require thin thickness, high refractive index, and excellent processability, such as surface coating materials for improving display brightness and micro lens arrays for digital camera sensors.

Professor Jiwoo Lim said, "The paradigm shift of using gaseous sulfur in polymer manufacturing became the foundation of ultra-high refractive index and high transparency polymer thin film manufacturing technology," adding, "It is expected to play a key role in realizing next-generation ultra-lightweight optical materials represented by flat lenses and meta lenses, as well as high-refractive-index materials in the future."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.