[Asia Economy Reporter Hwang Junho] Domestic researchers have developed a high-efficiency solar thermal membrane distillation technology that can produce drinking water from seawater or wastewater using solar energy. It is expected to be utilized for drinking water supply in places where water is difficult to obtain, such as water-scarce countries, domestic island regions, overseas deployment sites, and field army garrisons.

The joint research team of Dr. Song Kyung-geun from the Water Resources Circulation Research Center at the Korea Institute of Science and Technology (KIST) and Dr. Choi Won-jun from the Photovoltaic Materials Research Group announced on the 1st that they developed this technology and that the related research results were introduced in Desalination, an international journal in the water resources field.

Doubling the Productivity of Solar Thermal Membrane Distillation Water Production

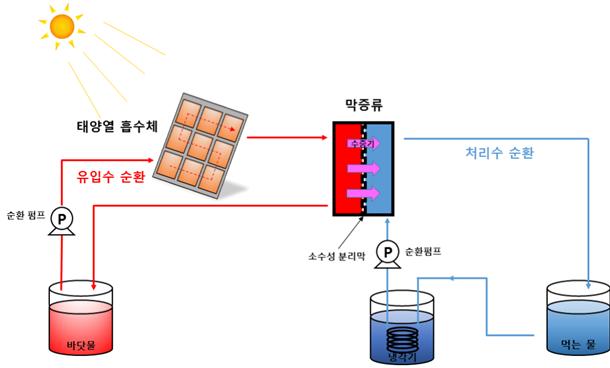

This is an overview diagram showing the operating principle of the solar thermal membrane distillation technology applied with the Ti/MgF2 solar thermal absorber developed by KIST researchers.

This is an overview diagram showing the operating principle of the solar thermal membrane distillation technology applied with the Ti/MgF2 solar thermal absorber developed by KIST researchers.

The research team developed a high-efficiency solar thermal membrane distillation technology. Membrane distillation is a desalination technology that produces drinking water from seawater. It heats seawater and passes it through a hydrophobic membrane that only allows water vapor to pass, then collects and condenses it to produce drinking water.

The team developed a solar thermal absorber, considered the core technology of 'solar thermal membrane distillation technology,' which uses solar heat as the heat source for membrane distillation. The solar thermal absorber collects solar energy and heats the water.

The absorber developed by the research team is composed of titanium metal and magnesium fluoride and has performance capable of dramatically increasing water production. This absorber absorbs more than 85% of solar energy in the wavelength range of 0.3 to 2.5 μm, which constitutes most of solar energy, and can heat water to over 80°C.

In actual membrane distillation tests, on a clear day in September, it was possible to produce 4.78 L/m2 of drinking water over 10 hours. This performance produces more than twice the amount of water compared to commercially available solar thermal absorbers.

Hope for Water-Scarce Countries

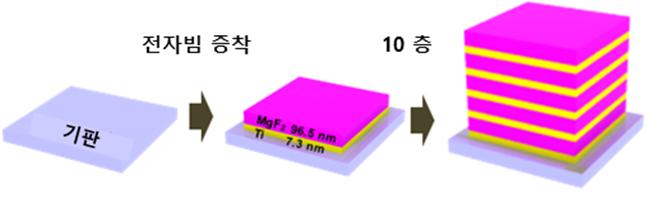

A solar heat absorber can be manufactured by alternately depositing 10 thin film layers on a substrate using the electron beam evaporation method.

A solar heat absorber can be manufactured by alternately depositing 10 thin film layers on a substrate using the electron beam evaporation method.

The research team explained that the new absorber can be manufactured by a simple method such as depositing a thin film only tens of nanometers thick and has excellent performance, so it can be applied not only to solar thermal membrane distillation but also to solar thermal boilers. In particular, it can be applied to isolated areas without energy infrastructure, making it possible to supply drinking water facilities in underdeveloped countries with water shortages or domestic island regions. It is also expected to be utilized as a military facility supplying drinking water in overseas deployment areas or field army garrisons.

Dr. Song said, "This research is a successful example of convergence research that created innovative results by combining material technology with water treatment technology," and added, "We plan to continue focusing on developing water treatment technologies applying cutting-edge material technologies through ongoing convergence research."

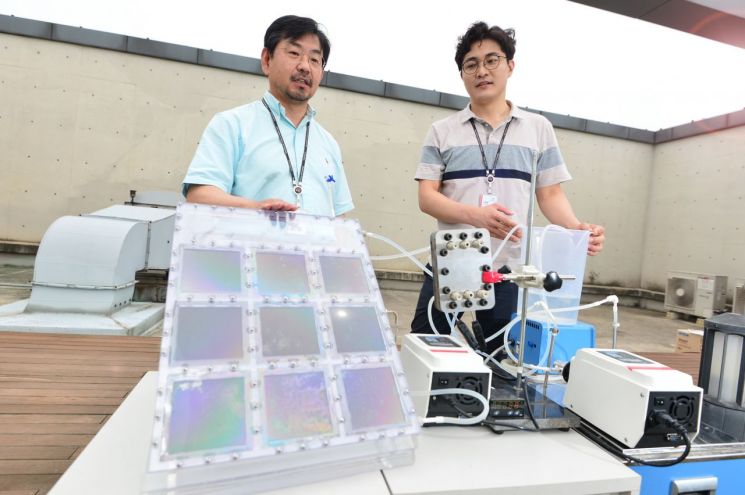

Senior Researcher Kyungkeun Song (corresponding author) and first author Jaewon Shin (Ph.D. candidate) at KIST, who led this study, are discussing the process in which water is efficiently produced through membrane distillation technology using a solar absorber (9 panels, size 5cm X 5cm).

Senior Researcher Kyungkeun Song (corresponding author) and first author Jaewon Shin (Ph.D. candidate) at KIST, who led this study, are discussing the process in which water is efficiently produced through membrane distillation technology using a solar absorber (9 panels, size 5cm X 5cm).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)