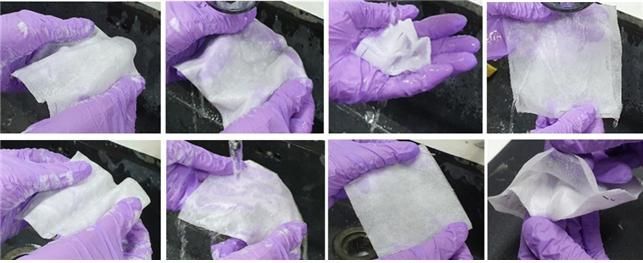

KAIST research team is hand-washing a 'nonwoven fabric-nanofiber filter-nonwoven fabric' sandwich filter.

KAIST research team is hand-washing a 'nonwoven fabric-nanofiber filter-nonwoven fabric' sandwich filter.

[Asia Economy Reporter Hwang Junho] Health masks that maintain performance even after washing are expected to be sold at around 2,000 won per mask. The research team that developed the mask plans to apply for approval from the Ministry of Food and Drug Safety (MFDS) this week, and if approved by the government, it is expected to play a significant role in resolving the mask shortage caused by the novel coronavirus infection (COVID-19).

Washable mask price around 2,000 won

Professor Kim Il-du of the Department of Materials Science and Engineering at KAIST appeared on MBC Radio's 'Kim Jong-bae's Focus' on the 17th and stated that the mask price is "considered to be around 2,000 won." According to KAIST, this mask consists of a mask and a filter and is expected to be sold at a price level of 2,000 to 3,000 won.

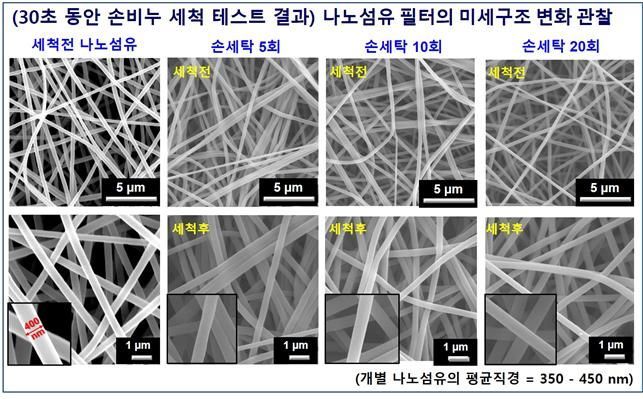

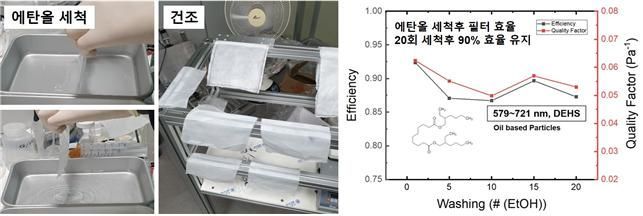

The mask developed by Professor Kim's research team is equipped with a nanofiber filter that maintains an initial filtration efficiency of over 94% even after more than 20 repeated washes. This filter is not significantly affected even after being soaked in ethanol for more than 3 hours. The research team stated, "In the case of sterilization and washing using ethanol, it can be used for more than a month."

Professor Kim explained the reason this mask is washable by saying, "In the case of nanofibers, it physically blocks particles rather than using an electrostatic method, so even if water or ethanol touches it, it is unrelated to electrostatics, making reuse possible."

He added, "This filter has a diameter of about 100 to 500 nanometers, which is about 1/20th the diameter of an MB filter. Therefore, even without electrostatics, physical blocking is possible."

In the case of general nanofiber masks, filters without fiber orientation are used. These are completed through a process where fibers are spun and then exposed to high voltage. These filters use electrostatics to filter out fine dust and other particles in the air. However, when moisture or water touches them, the electrostatics disappear, making reuse impossible.

MFDS approval pending

Professor Kim will request approval from the MFDS this week to commercialize this mask. Although MFDS approval is known to take about 55 days, it is expected that regulations and procedures will be simplified due to the recent spread of COVID-19. Once approval is granted, Professor Kim plans to increase production from the current level of 1,500 units to 50,000 units.

Professor Kim said, "I think there will be no cases where nanoparticles smaller than 100 nanometers fall off or fibers break very short and enter the nose, but since such concerns may exist, verification work is necessary." He continued, "When synthesizing nanofibers, organic solvents are used, and there is a need to check whether any residual solvents remain inside the nanofibers, so procedures to confirm this are required."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.