[Asia Economy Reporter Junho Hwang] A domestic research team has devised a method to prevent the high oxidizability, a weakness of MXene, which is expected to have high utility in electromagnetic wave shielding and sensor electrodes. The commercialization of MXene, including the development of electrodes utilizing its excellent electrical conductivity, is expected to accelerate.

The Korea Institute of Nanotechnology announced on the 20th that it has succeeded in developing a technology that dramatically improves the oxidation stability of MXene materials through a Korea-US joint research effort.

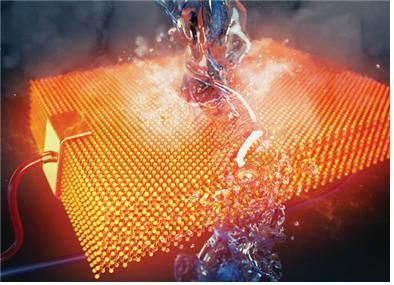

MXene is a two-dimensional plate-like material with excellent electrical conductivity. MXene exhibits outstanding performance in energy electrodes, sensor electrodes, and electromagnetic wave shielding. Accordingly, although the material has been developed for less than 10 years, active research is being conducted in the United States, China, South Korea, and other countries.

However, easy oxidation has been a major obstacle to commercialization. When titanium carbide MXene is stored at room temperature, an oxidation reaction occurs, transforming it into titanium dioxide (TiO2), causing it to lose its electrical properties. Especially in environments with moisture, it converts to titanium dioxide much faster, and research to solve this problem has been underway.

Improvement of MXene Oxidation through Heat Treatment

Dr. Lee Yonghee and Dr. Ahn Chiwon from the Korea Institute of Nanotechnology, Dr. Kim Seonjun from the Korea Institute of Science and Technology, the Korea-US Joint Research Center team, and researchers from Yury Gogotsi's group at Drexel University in the United States have found a way to improve the strong oxidizability of MXene.

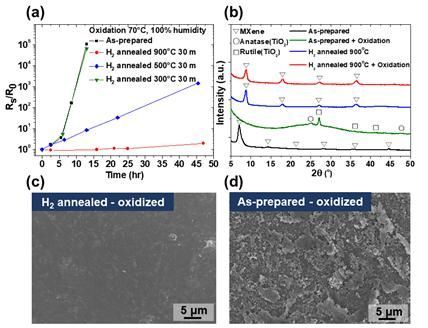

The research team improved the oxidizability of titanium carbide MXene films by high-temperature heat treatment (high-temperature annealing) in a hydrogen and argon mixed gas atmosphere. For the heat-treated MXene film, resistance increased by 1.9 times over 48 hours. Compared to untreated films, where resistance increased more than one million times in just 13 hours, the oxidizability was significantly improved. Additionally, the heat-treated MXene film showed almost no change in resistance even after being immersed in water for 24 hours.

Furthermore, the research team reported that applying heat treatment to partially oxidized MXene films resulted in a recovery of the resistance increased by oxidation. The same improvement in oxidation stability was observed when the developed MXene films were applied to nano electric heaters.

Contribution to MXene Commercialization

The research team expects this study to greatly contribute to accelerating the commercialization of MXene, a nano new material with excellent electrical conductivity.

Dr. Lee Yonghee stated, "One of the biggest obstacles hindering the commercialization of MXene materials is their low oxidation stability. Through the development of oxidation-resistant MXene films, a foundation has been laid for expanding applications such as MXene-based long-life devices and devices for extreme environments."

This research paper was published as the cover article in the January issue of the international journal Journal of Materials Chemistry A (IF=10.7).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)