Climate Ministry Unveils Industrial Electricity Tariff Reform Plan

Nighttime Operation of Cement Kilns Unavoidable

Electricity Cost Share Likely to Rise by 3% to 4%

"Additional Measures Needed Reflecting Process Characteristics"

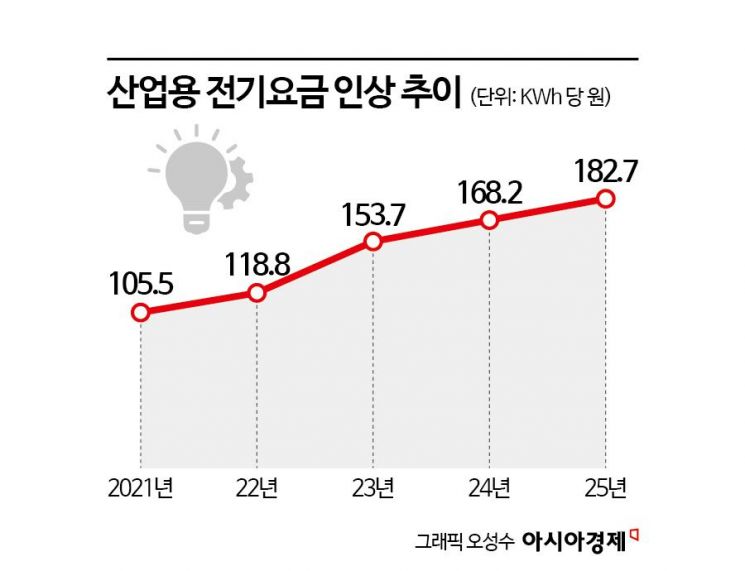

As the government has unveiled an "industrial electricity tariff reform plan" that lowers daytime rates and raises nighttime rates, concerns are mounting that electricity costs could rise significantly, especially for industries such as cement and paper, where 24-hour operations are unavoidable. Critics argue that, because the nature of these processes makes time-of-use flexibility impossible, the government needs to introduce additional measures that take industrial structures into account.

According to related industry sources on the 4th, if the industrial electricity tariff reform plan proposed by the Ministry of Climate, Energy and Environment is implemented, the share of electricity costs in the manufacturing cost of the cement industry is expected to increase by an average of about 1% to 5%. The cement manufacturing process is largely divided into mining, calcination, cooling, and shipping. Among these, during the calcination stage, where clinker, the key raw material for cement, is produced, the kiln (furnace) operates 24 hours a day. Because stopping the kiln even once incurs additional restart costs of several hundred million won, the cement industry is seen as having little way to avoid the impact of higher nighttime electricity rates. According to the industry, electricity currently accounts for an average of about 30% of cement manufacturing costs.

An industry official said, "Even now, we already pay electricity bills amounting to several hundred billion won every year, so even a 1% to 2% increase in the share would mean a substantial additional burden," adding, "We will have to see the detailed guidelines of the reform plan, but it appears that the share of electricity in total manufacturing costs will rise by around 3% to 4%."

The paper industry, where key production facilities such as paper machines operate around the clock, is also paying close attention to the reform plan. Given the structural characteristic that the operation of major base paper production facilities such as large motors, pumps, and fans is concentrated at night, the sector is analyzed to be more directly exposed to the impact of higher nighttime electricity rates. According to the industry, electricity accounts for about 15% of total manufacturing costs in the paper industry, and purchased power from outside sources makes up around 30% of total power consumption.

Some observers also detect a "temperature gap" depending on each company’s capacity to respond. Companies that can partially absorb the increase in electricity rates through energy storage systems (ESS) or in-house power generation facilities are in a different position from those that have a high proportion of aging equipment or lack investment capacity, which are now more likely to bear the full brunt of the reform plan. An ESS is a system that stores electricity and supplies it again when needed; by charging electricity during relatively cheaper time periods and using it during more expensive time periods, companies can reduce their electricity cost burden.

An industry official stressed, "We agree with the policy objective of dispersing power demand, but the government needs to consider more meticulous measures, such as separate tariff schemes or supplementary mechanisms that reflect process characteristics and company size."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.