Joint Research Team Develops Technology for Hydrogen Storage and Release in Liquid Derived from Waste Styrofoam

Improving Plastic Recycling Rates and Offering an Alternative for Hydrogen Storage and Transport, Featured in ACS Catalysis

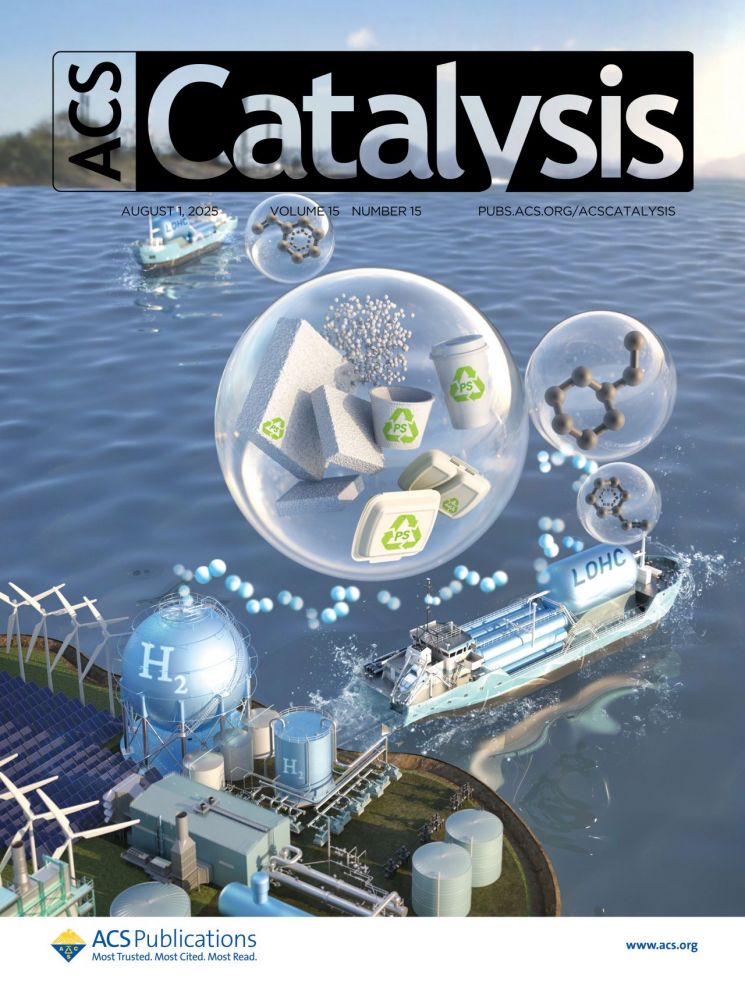

A technology has been developed that allows hydrogen to be stored in polystyrene-derived materials, such as those commonly known as 'Styrofoam', and then extracted for use when needed.

This opens the way to increase the recycling rate of polystyrene, which is currently less than 1%, and to handle hydrogen, which is difficult to store and transport in its gaseous state, more easily.

A research team led by Professor Ahn Kwangjin of the Department of Energy and Chemical Engineering at UNIST, in collaboration with Dr. Son Hyuntae of KIST and Professor Han Jihoon’s team at POSTECH, has developed a full-cycle system that thermally decomposes waste polystyrene, converts it into a liquid organic hydrogen carrier (LOHC), and recovers the stored hydrogen at high purity.

Research team: Professor Kwangjin Ahn of UNIST, Dr. Hyuntae Son of KIST, Professor Jihoon Han of POSTECH, and Researcher Hyungeon Lee of UNIST (first author). Provided by UNIST

Research team: Professor Kwangjin Ahn of UNIST, Dr. Hyuntae Son of KIST, Professor Jihoon Han of POSTECH, and Researcher Hyungeon Lee of UNIST (first author). Provided by UNIST

LOHC is a hydrogen storage medium in which hydrogen is chemically bonded to the ring-shaped structure of the material, and can later be released by heat and a catalyst. Because it is in liquid form, it can be stored for long periods at room temperature and atmospheric pressure, and it is compatible with existing petroleum transport infrastructure.

The research team developed this technology by focusing on the fact that polystyrene is a polymer containing many aromatic rings. When polystyrene is heated, low-molecular-weight aromatic ring compounds such as styrene and toluene are produced through decomposition. These compounds are then reacted with hydrogen gas at high temperatures to store hydrogen, and later, hydrogen is separated again through a dehydrogenation reaction.

Catalysts were used for hydrogen storage and separation. A ruthenium catalyst was used for storage, and a platinum catalyst was used for release. The efficiency of hydrogen release varies greatly depending on the structure of the metal oxide support coated with the platinum catalyst, and it was found that nanosheet-form aluminum oxide exhibited both excellent reactivity and stability.

To address the issue of deposits accumulating on the catalyst surface, a fractional distillation process was employed. This method removes impurities in advance to extend the catalyst’s lifespan.

The efficiency and economic feasibility of the process were also analyzed. Instead of supplying heat from an external source for pyrolysis, the process utilizes waste generated during the process as its own heat source by combustion, thereby reducing energy consumption and increasing the amount of polystyrene that can be processed.

The joint research team stated, "This study is the world’s first case of applying compounds derived from waste polystyrene to actual hydrogen storage and release. As a strategy that addresses both waste utilization and hydrogen storage, we believe it has high potential for application in industrial settings and policy development in the future."

This research was supported by the Mid-Career Researcher Program and the group research ERC project (Research Center for Chemical/Bio Convergence Processes for Microplastics Response) of the Ministry of Science and ICT and the National Research Foundation of Korea. The results were selected as a back cover paper in the prestigious journal 'ACS Catalysis' and published on August 1.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.