Efficiency and Lifespan of Solar Cells Improved Simultaneously with Camphor Derivative

Efficiency Increased by 9.6% and Lifespan More Than Doubled with Camphor-Based Additive, Published in Energy & Environmental Science

A research team has reported results showing improved quality of solar cell thin films using a substance derived from camphor.

This achievement was made possible by utilizing the sublimation properties of this substance, which, like dry ice, evaporates without leaving any residue.

On June 29, Professor Changduk Yang’s team from the Department of Energy and Chemical Engineering at UNIST announced that they had synthesized high-quality perovskite thin films by adding a camphor derivative. Because no residual substances remain, the efficiency and lifespan of the solar cells can be improved, and the process can be simplified, which is expected to reduce manufacturing costs.

The perovskite thin film in solar cells is composed of numerous crystal grains. The larger and more uniformly arranged these crystals are, the smoother the flow of electrons and the more robust the structure becomes, resulting in improved efficiency and lifespan of the cells. Additives are used to create such high-quality structures, but if these additives remain after manufacturing, they can actually cause a decline in performance.

Professor Changduk Yang. Provided by UNIST

Professor Changduk Yang. Provided by UNIST

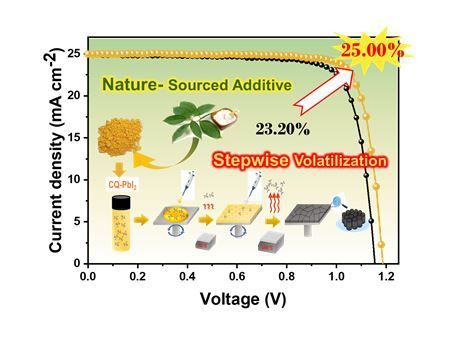

To solve this problem, the research team used 'camphorquinone' as a thin film additive. Camphorquinone is a substance in which an oxidizing functional group is added to camphor, which is extracted from camphor trees. Like camphor, it sublimates directly from solid to gas, but unlike camphor, it sublimates in a stepwise manner.

During the first heat treatment, it helps form uniform crystal seeds and partially sublimates; the remainder stays sufficiently within the thin film until the main crystal growth stage, and then completely sublimates during the second heat treatment.

Research team, (from left) Jiwon Park, Researcher (First Author), Byungkyu Lee, PhD, Wonjun Kim, Researcher. Provided by UNIST

Research team, (from left) Jiwon Park, Researcher (First Author), Byungkyu Lee, PhD, Wonjun Kim, Researcher. Provided by UNIST

Jiwon Park, the first author and researcher, explained, "Camphorquinone can be controlled to act precisely during the crystal growth stage, and it leaves absolutely no residue in the thin film. Thanks to these properties, we were able to produce high-quality thin films."

Solar cells using this crystalline thin film achieved a power conversion efficiency (PCE) of 25.2%. This is about 9.6% higher than the control group without the additive, which recorded 23.0%. Under Maximum Power Point Tracking (MPPT) conditions, which simulate real operating environments, the cells maintained over 90% of their initial efficiency for 1,000 hours, demonstrating more than double the lifespan performance compared to the control group.

MPPT is a state where the solar cell is set to deliver maximum output under artificial sunlight, and is considered one of the most stringent criteria for lifespan evaluation.

Improved the efficiency and lifespan of perovskite solar cells by utilizing the stepwise sublimation characteristics of substances derived from camphor.

Improved the efficiency and lifespan of perovskite solar cells by utilizing the stepwise sublimation characteristics of substances derived from camphor.

Professor Changduk Yang stated, "It is significant that we were able to address the stability issues of perovskite solar cells using eco-friendly substances derived from nature. This technology can contribute both to the sustainability of the solar industry and to the advancement of its technology."

The research results were published on June 21 in Energy & Environmental Science (IF 30.8), the most prestigious journal in the field of eco-friendly energy.

This research was supported by the National Research Foundation of Korea under the Ministry of Science and ICT, and by the Korea Institute of Energy Technology Evaluation and Planning under the Ministry of Trade, Industry and Energy.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.