The Birth of 'E-GMP' Amid the Platform Wars

Hyundai Motor Group's Secret Weapon: The Next-Generation eM Platform

Every April, the automotive industry's attention turns to New York. This is to check the results of the World Car Awards' "World Car of the Year (WCOTY)," held at the New York Auto Show. Alongside the North American and European Car of the Year awards, the WCOTY is considered one of the world's three most prestigious automotive honors. Its authority and symbolism are especially notable because it evaluates vehicles on a global scale, not just within a specific region. Only new cars that have sold more than 10,000 units annually across at least two continents are eligible, and they must pass rigorous evaluations in areas such as performance, value, safety, eco-friendliness, market significance, emotional appeal, and innovation to claim the top prize. The judging panel consists of over 100 automotive journalists from more than 30 countries worldwide.

Hyundai Motor Group has won this award for four consecutive years through 2025. Starting with the Ioniq 5 in 2022, followed by the Ioniq 6 in 2023, the EV9 in 2024, and the EV3 in 2025, Hyundai and Kia have earned the honor of being named "the world's best new car." It is a remarkable achievement for a Korean brand to win this highly coveted award four years in a row?and with electric vehicles each time. In addition to the WCOTY, Hyundai and Kia's electric vehicles have swept various other automotive awards, including European, UK, and Denmark Car of the Year, Top Gear Awards, and Car and Driver Awards. As a result, the industry is focusing on Hyundai Motor Group's innovative technological capabilities. Attention is especially drawn to Hyundai's dedicated electric vehicle platform, E-GMP, since all four consecutive WCOTY-winning vehicles were built on this same platform.

The Birth of 'E-GMP' Amid the Platform Wars

Hyundai Motor Group officially unveiled E-GMP at the end of 2020 and began applying it to mass-produced vehicles starting in 2021. When the platform was first revealed in 2020, major global manufacturers such as Tesla, Volkswagen (MEB), and GM (Ultium) were already developing or had commercialized their own electric vehicle platforms. As a relatively late entrant to dedicated EV platforms, Hyundai Motor Group needed to demonstrate an overwhelming technological advantage to catch up. To this end, Hyundai introduced an electric vehicle platform featuring advanced technologies such as ultra-fast multi-charging, bidirectional charging (V2L), and a battery pre-heating system. Among mainstream brands, Hyundai and Kia were the only manufacturers to implement such a wide array of innovative technologies.

First, Hyundai and Kia were the industry's first to introduce ultra-fast charging technology using an 800V high-voltage system in the E-GMP platform. Thanks to this, electric vehicles built on E-GMP can accept 350kW-class power and reduce the time needed to charge the battery from 10% to 80% from around 30 minutes to just 18 minutes. With about five minutes of charging, the vehicle can travel approximately 100km, and once fully charged, it is designed to drive over 500km on a single charge.

Traditional automakers have widely used 400V voltage systems in electric vehicles. Everything from charging stations to EV components has been developed to match the 400V standard. However, Hyundai Motor Group believed that a paradigm shift was necessary to drastically reduce charging times.

The output power (P) of a charger is calculated as the product of voltage (V) and current (I) (P=V×I). To increase power, either voltage or current must be increased. If current is increased, cables and connectors become thicker and heavier, and heat generation becomes a bigger problem. On the other hand, increasing voltage reduces the required current, allowing for thinner, lighter cables and less heat and energy loss. Hyundai therefore chose to raise the system voltage in its EVs from 400V to 800V. As a result, it was able to commercialize electric vehicles compatible with 350kW-class ultra-fast chargers and significantly reduce charging times.

Hyundai also considered real-world charger usage. Most chargers commonly found around us are 400V systems with output ranging from 50 to 250kW. If only the EVs advance to 800V, even the best advanced technology could become useless. To address this, Hyundai developed a multi-fast charging system that is compatible with both 400V and 800V. When a 400V fast charger is connected to the vehicle, an integrated inverter inside the drive motor boosts the voltage to 800V to charge the high-voltage battery. Hyundai developed this technology so that voltage conversion occurs automatically within the E-GMP system, without the need for a separate adapter or controller. This world-first technology is patented by Hyundai Motor Group.

Another weapon of Hyundai and Kia's E-GMP-based electric vehicles is V2L (vehicle to load). V2L is a bidirectional charging technology that allows the power stored in the EV battery to be supplied to external devices. With this technology, an electric vehicle can function as a large, mobile auxiliary battery. E-GMP can supply up to 3.6kWh of power externally?enough to connect and use home appliances or electronic devices during outdoor activities without a separate generator or additional equipment. Hyundai and Kia are the only brands to offer V2L functionality across nearly all major EV lineups.

The final noteworthy technology is the battery pre-heating system. Typically, battery charging speed drops significantly as ambient temperature decreases. Lithium-ion battery ions move between the anode and cathode through a liquid electrolyte, repeating charging and discharging cycles. If the electrolyte solidifies in cold winter weather, battery performance drops sharply and charging times increase. To prevent this, Hyundai installed a pre-heating system outside the battery pack that rapidly raises the battery temperature during charging, ensuring the electrolyte remains in a liquid state.

Why Is the Electric Vehicle Platform Important?

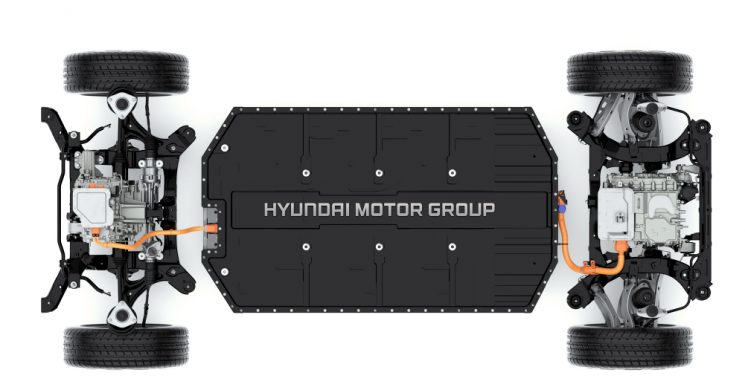

Most automakers began introducing dedicated electric vehicle platforms around 2020. Tesla, a newcomer that produces only electric vehicles, had already applied such a platform as early as 2012, sparking a wave of change in the market. Tesla adopted a skateboard platform, laying the battery flat on the floor and integrating the motor and major components into the lower frame of the vehicle. This skateboard approach became the model for dedicated EV platforms in the industry. Even when traditional automakers launched their own advanced EV platforms in the 2020s, many adopted this method.

The flat battery layout brought new freedom to vehicle design. Unlike internal combustion engine cars, there is no need for complex structures such as an engine compartment, transmission, or exhaust system, allowing for a completely flat floor. Manufacturers can simply build the desired body shape on top of this flat base. The interior space is also much larger, giving designers more freedom. Placing the battery on the floor lowers the center of gravity, which improves driving stability and cornering performance.

Efficiency is also improved in vehicle development and production. Modularizing the platform allows for easy adjustment of length and width to suit different vehicle types. This means a single platform can be used to produce sedans, SUVs, small cars, and large vehicles. Naturally, development and production costs are reduced.

Hyundai Motor Group's Secret Weapon: The Next-Generation eM Platform

Having recognized the importance of EV platform development through E-GMP, Hyundai Motor Group plans to launch its next-generation platform as early as 2026. Although the application of the new platform to mass-produced vehicles has been delayed due to the temporary demand slowdown known as the "EV chasm," market expectations for Hyundai's innovative EV technologies remain high.

Moreover, over the past five years since the 2020s, competition in EV platform technology has intensified due to the rapid rise of Chinese EV manufacturers. In March, BYD, China's top EV company, unveiled its "Super e Platform," which enables a driving range of 400km on just a five-minute charge. This EV platform uses a 1000V system and supports charging speeds of up to 1000kW. In terms of the "C" value?which represents the ratio of charging output to battery capacity?it achieves 10C. This means the battery can be charged at 10 times its capacity, theoretically enabling a full charge in just six minutes. This charging speed rivals that of refueling an internal combustion engine vehicle.

Hyundai Motor Group is also expected to face growing challenges in response. The company already secured 8C-level charging technology two years ago, and it is considered only a matter of time before it reaches 10C. However, securing a technology and commercializing it are separate issues. While technology development can be accelerated, commercialization and product launches must also take into account market maturity, development costs, and consumer pricing.

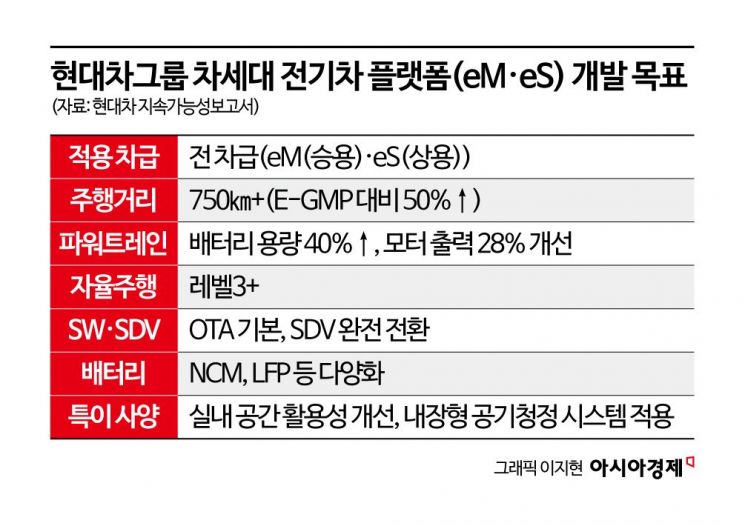

The next-generation eM platform, which Hyundai Motor Group is developing with a target launch in 2026, is expected to once again change the paradigm of the electric vehicle market. According to development goals, it aims to improve driving range by more than 50% compared to E-GMP (with an expected range of over 750km), increase battery capacity by 40% while reducing fast-charging time, and boost motor output by over 28% while maintaining top-level energy efficiency. Additional objectives include a structure that prevents battery exposure to flames in the event of a fire, Level 3 autonomous driving technology, improved interior space utilization (such as dual doors without a B-pillar), standard over-the-air software updates (OTA), and a built-in air purification system. Ultimately, the future leadership of the EV market will depend on who can evolve their platform faster and more precisely. This is why Hyundai Motor Group's next move is highly anticipated.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.