'Explosion Prevention' Heat Exchanger Defect Detection by AI

Diagnostic Accuracy of 95%, Interpretation Time Reduced by 98%

A Fruitful Collaboration Between a Major Corporation and a Startup... Expanding Win-Win Cooperation

The non-destructive inspection automation solution jointly developed by SK Innovation and the Ulsan-based artificial intelligence (AI) startup Deep AI has received the government’s New Excellent Technology (NET) certification. This marks the first time that an AI-based technology in the field of industrial facility diagnostic automation has been awarded the NET certification.

On June 15, SK Innovation announced that the "AI Heat Exchanger Non-Destructive Inspection Automated Evaluation Solution," developed in collaboration with Deep AI, has received New Excellent Technology certification from the Ministry of Trade, Industry and Energy. The NET certification is an official recognition granted under the Industrial Technology Innovation Promotion Act to technologies that are either developed for the first time in Korea or significantly improve upon existing technologies. It comprehensively evaluates a technology’s originality, completeness, and industrial impact. Currently, there are 111 technologies with valid certification.

The non-destructive inspection AI solution for heat exchangers, jointly developed by SK Innovation and the Ulsan-based AI startup Deep AI, has received the New Excellent Technology (NET) certification from the Ministry of Trade, Industry and Energy. SK Innovation

The non-destructive inspection AI solution for heat exchangers, jointly developed by SK Innovation and the Ulsan-based AI startup Deep AI, has received the New Excellent Technology (NET) certification from the Ministry of Trade, Industry and Energy. SK Innovation

The newly certified solution automatically analyzes ultrasound images of the interior of heat exchangers using AI to determine the presence of defects. Previously, image interpretation had to be performed manually by skilled experts. However, this solution enables AI to evaluate data in real time, achieving a diagnostic accuracy of over 95% and reducing interpretation time by approximately 98% compared to conventional methods.

SK Innovation provided on-site demonstration facilities, operational data, and maintenance expertise at its Ulsan Complex, while Deep AI integrated AI analysis technology to implement an automated evaluation system that can be immediately applied in the field. The solution was developed with support from the "Manufacturing AI Convergence Infrastructure Project" promoted by Ulsan Metropolitan City and the Ulsan Information Industry Promotion Agency. It is being recognized as a cooperative industrial AI model created through collaboration among a large corporation, a startup, and a local government.

Heat exchangers, composed of thousands of tubes, are core equipment responsible for temperature control in refining and petrochemical processes. There are about 7,000 units installed at the SK Innovation Ulsan Complex and around 30,000 units across the entire Ulsan Petrochemical Industrial Complex. Tube damage accounts for more than 80% of all equipment failures, making it a leading cause of major accidents and necessitating regular non-destructive inspections.

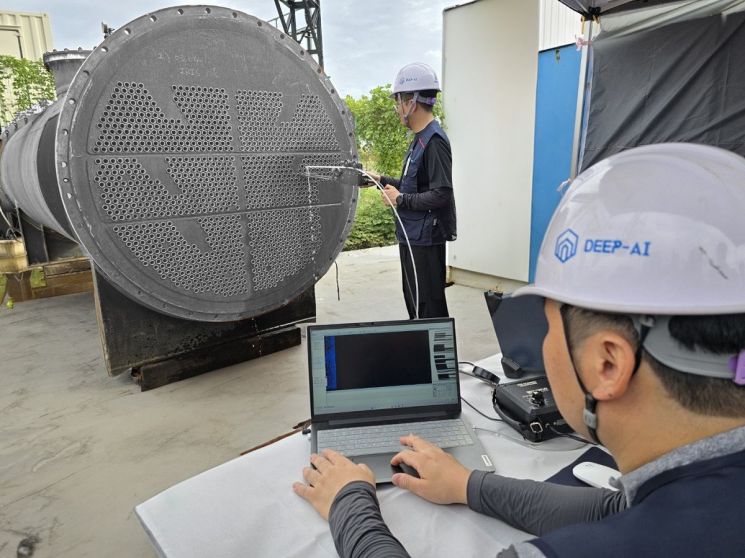

Workers are inspecting heat exchanger defects using an AI-based nondestructive testing solution at SK Innovation Ulsan Complex. SK Innovation

Workers are inspecting heat exchanger defects using an AI-based nondestructive testing solution at SK Innovation Ulsan Complex. SK Innovation

SK Innovation and Deep AI plan to use this NET certification as a stepping stone to expand the application of their solution beyond refining and petrochemicals to other industries such as power generation, batteries, and steel. Deep AI is a startup supported by Korea Hydro & Nuclear Power (KHNP) and is also considering entering the next-generation nuclear power market, including small modular reactors (SMRs).

An SK Innovation representative stated, "We will continue to collaborate with Deep AI to achieve innovation in AI and data-based technologies, thereby enhancing both the safety and competitiveness of industrial sites."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.