SK On Develops Technology to Triple the Lifespan of All-Solid-State Batteries

Lithium Nitride Protective Layer Enables Over 300 Charge-Discharge Cycles

Collaboration with Academia Leads to Key Advances in Next-Generation Battery Commercialization

SK On announced on May 6 that research conducted in collaboration with Professor Kim Dongwon's team at Hanyang University, which extended the lifespan of sulfide-based all-solid-state batteries, was published in the April issue of "ACS Energy Letters," an internationally recognized journal in the energy and chemistry fields.

Lithium metal, which is attracting attention as a next-generation anode material for all-solid-state batteries, is emerging as a key to improving energy density and achieving high output, thanks to its capacity?about 10 times greater than conventional graphite?and its low electrochemical potential.

However, due to the reactive nature of lithium metal in air, inorganic substances form unevenly on its surface, resulting in reduced charge-discharge efficiency and a shorter battery lifespan. When a lithium metal anode is used, the number of charge-discharge cycles at room temperature is limited to 100.

To address this issue, SK On immersed the lithium metal anode in a special solution to remove inorganic substances and formed a protective layer based on highly conductive lithium nitride (Li3N) and mechanically strong lithium oxide (Li2O).

As a result, interfacial stability was secured, and more than 300 charge-discharge cycles at room temperature became possible, effectively tripling the lifespan of conventional anode metal batteries. SK On has applied for domestic and international patents for this technology.

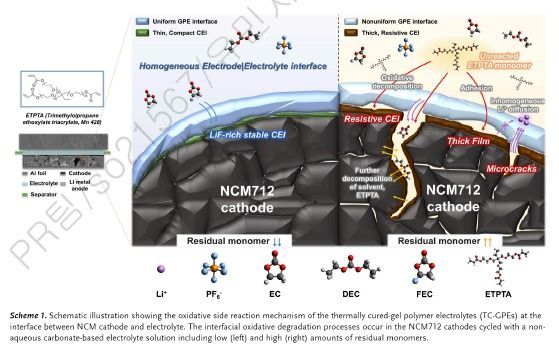

SK On, in collaboration with Professor Park Jonghyuk's team at Yonsei University, also identified the relationship between the curing time of gel polymer electrolyte (GPE) in polymer oxide composite batteries and battery lifespan. This research was published in February in "Angwandte Chemie," an international journal in the field of chemistry.

According to the study, a longer thermal curing time for the gel polymer electrolyte is advantageous for maintaining battery performance.

When a battery used an electrolyte thermally cured for 60 minutes, its discharge capacity decreased by 9.1%. In contrast, when the curing time was only 20 minutes, the discharge capacity dropped by about 34%.

SK On expects that these research results will contribute to extending the lifespan of polymer oxide composite batteries.

Park Kisoo, Head of R&D at SK On, stated, "These achievements are the result of SK On's ongoing research and development efforts and technological capabilities, realized through collaboration with academia. They will serve as a key foundation for overcoming the technical challenges of solid-state batteries, which are gaining attention as next-generation batteries."

SK On is currently developing two types of all-solid-state batteries?polymer oxide composites and sulfide-based batteries?with the goal of commercializing them by 2028 and 2030, respectively.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.