Establishing a 1.2 Million Unit Local Production System

Promoting Localization of Parts and Building an Electric Furnace Steel Mill

Expanding Cooperation with Innovative U.S. Companies

Investing 24.3 Trillion KRW Domestically This Year

Hyundai Motor Group will invest $21 billion, approximately 30.8 trillion KRW, in the United States over the next four years starting this year.

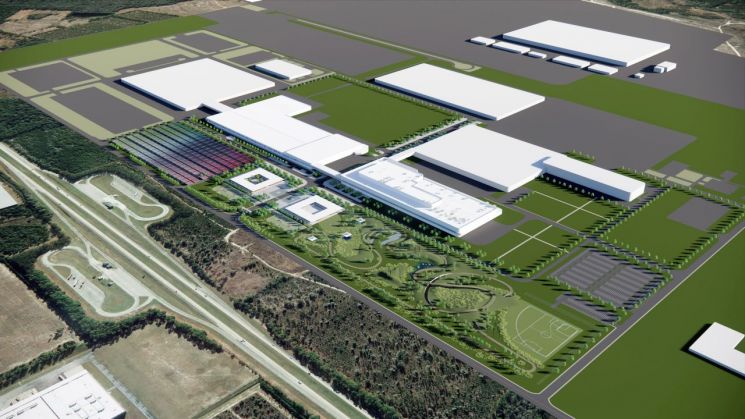

On the 24th (local time), Hyundai Motor Group announced its investment plan in key sectors such as automobiles, parts and logistics, steel, and future industries in the U.S. through 2028. The production capacity of Hyundai Motor Group Meta Plant America (HMGMA), which is about to be completed, will be expanded from the current 300,000 units to 500,000 units, and an electric furnace integrated steel mill will be constructed in Louisiana. The group plans to expand cooperation with U.S. companies in future industries such as robotics and artificial intelligence (AI), and also invest in energy-related infrastructure.

Through this investment, Hyundai Motor Group aims to respond to the policies of the Donald Trump administration, such as rebuilding U.S. manufacturing, while expanding business opportunities in various fields and strengthening its status as a top-tier company in the U.S. The large-scale investment by Hyundai Motor Group is expected to promote economic revitalization in both Korea and the U.S. and further expand economic cooperation between the two countries.

Hyundai Motor Group Chairman Chung Euisun is speaking at the '2025 Hyundai Motor Group New Year Meeting' held on the 6th at Hyundai Motorstudio in Goyang-si, Gyeonggi-do. Photo by Kim Hyunmin

Hyundai Motor Group Chairman Chung Euisun is speaking at the '2025 Hyundai Motor Group New Year Meeting' held on the 6th at Hyundai Motorstudio in Goyang-si, Gyeonggi-do. Photo by Kim Hyunmin

Establishing a 1.2 Million Unit Local Production System in the U.S... Building an Electric Furnace Steel Mill

Hyundai Motor Group's investment in the U.S. is divided into ▲automobiles ▲parts, logistics, and steel ▲future industries and energy sectors. In the automobile sector, Hyundai Motor Group will invest a total of $8.6 billion to establish a local production system of 1.2 million units in the U.S.

Starting with the Hyundai Motor Alabama plant (360,000 units) which began operations in 2004, followed by the Kia Georgia plant (340,000 units) in 2010, and the completion of HMGMA (300,000 units) this year, Hyundai currently has a production capacity of 1 million units in the U.S.

First, production capacity will be expanded to a total of 500,000 units by increasing HMGMA by 200,000 units. The Alabama and Georgia plants will also undergo modernization and efficiency improvements of production facilities to continuously produce high-quality new vehicles. The goal is to firmly establish the foundation for a 1.2 million unit production system in the future.

In the parts, logistics, and steel sectors, Hyundai Motor Group and its affiliated parts, logistics, and steel companies, which entered the U.S. market alongside Hyundai and Kia, will spend a total of $6.1 billion to strengthen the supply chain between finished vehicle manufacturers and parts suppliers. Facilities will be expanded in line with the increase in HMGMA production capacity to raise the localization rate of parts and promote local procurement of key electric vehicle components such as battery packs.

An electric furnace steel mill with a capacity of 2.7 million tons will be constructed in Louisiana. This steel mill, specialized in low-carbon automotive steel sheets, will enhance resilience against uncertain external risks such as tariffs by locally supplying high-quality automotive steel sheets. It is also expected to secure new growth engines in the steel sector by generating stable profits based on solid steel demand.

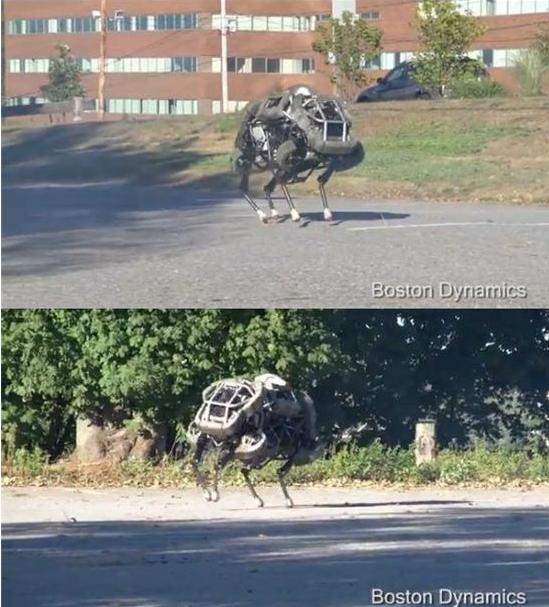

In the future industries and energy sector, $6.3 billion has been allocated. Cooperation with U.S. companies related to new technologies such as autonomous driving, robotics, AI, and Advanced Air Mobility (AAM) will be expanded, and the commercialization of Hyundai Motor Group’s U.S. subsidiaries Boston Dynamics, Supernal, and Motional will be accelerated.

Hyundai Motor Group is conducting various projects to intelligentize core mobility solutions such as SDV (Software Defined Vehicle) and robotics with NVIDIA and to strengthen AI technology application across business operations. It is also collaborating with U.S. autonomous driving company Waymo to expand the autonomous taxi service 'Waymo One' using the Ioniq 5 produced at HMGMA in the U.S.

Boston Dynamics and the 'Robotics and AI Institute (RAI)' are enhancing capabilities to develop intelligent robots based on reinforcement learning. Supernal aims for commercialization of AAM aircraft by 2028 and is collaborating with several U.S. states on unmanned aircraft testing. Motional, Hyundai’s U.S. autonomous driving subsidiary, is advancing Level 4 and above autonomous driving technology using autonomous driving data collection and AI model training.

▲Spot robot unveiled (Source: Boston Dynamics YouTube video)

▲Spot robot unveiled (Source: Boston Dynamics YouTube video)

Hyundai Motor Group is also discovering promising future technology startups and making proactive investments. It supports nuclear and renewable energy sectors and the expansion of electric vehicle charging stations. Hyundai Engineering & Construction is pushing to start construction of a Small Modular Reactor (SMR) in Michigan with Holtec International by the end of this year. Hyundai Engineering acquired the rights to a solar power plant project in Texas last year and is accelerating preparations for commercial operation in the first half of 2027. Through IONNA, an alliance of electric vehicle ultra-fast charging services with U.S. automakers, Hyundai plans to expand charging station installations.

Record Domestic Investment of 24.3 Trillion KRW

Hyundai Motor Group is also expanding domestic investment. Earlier this year, the group announced it would invest a record 24.3 trillion KRW this year to strengthen future competitiveness centered on Korea as a mobility innovation hub. This amount is more than 19% higher than the 20.4 trillion KRW invested in 2024. The investment will be allocated as ▲11.5 trillion KRW for research and development (R&D) ▲12 trillion KRW for capital expenditure ▲800 billion KRW for strategic investment.

R&D investment will be used to secure core future capabilities such as product competitiveness enhancement, electrification, SDV, hydrogen products, and fundamental technology development. Capital expenditure will be invested in expanding production facilities for electric vehicle (EV) transition and new models, manufacturing technology innovation, and infrastructure improvements such as customer experience hubs. Strategic investment will be executed to enhance competitiveness in core future businesses such as autonomous driving, software, and AI.

In particular, large-scale investment will be made in building EV-dedicated plants. The Kia Hwaseong EVO Plant is scheduled to be completed in the second half of this year, where customer-tailored Purpose Built Vehicles (PBV) will be produced in earnest. The Hyundai Motor Ulsan EV-dedicated plant, under construction with a target operation date in the first half of 2026, plans to mass-produce various models starting with a large SUV electric vehicle model.

A Hyundai Motor Group official stated, "The large-scale investments in Korea and the U.S. reflect our determination to strengthen future competitiveness through active challenges, continuous change, and innovation without shrinking in uncertain management environments, while creating new possibilities for humanity. We will create future opportunities through bold investments, internalization of core technologies, and strategic cooperation with top-tier companies domestically and internationally."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.