International Collaboration Between KAIST and University of Toronto

Expected to Reduce Fuel Consumption and Enhance Performance in Aerospace and Automotive Industries

Through international collaborative research, a material with ultra-lightweight and high-strength performance has been developed, enabling its application in various industries through customized design.

On the 18th, the research team led by Professor Seunghwa Yoo of the Department of Mechanical Engineering at the Korea Advanced Institute of Science and Technology (KAIST) announced that, in collaboration with Professor Tobin Filleter’s team at the University of Toronto, they developed a nano lattice structure that maximizes lightweight properties while maintaining high stiffness and strength.

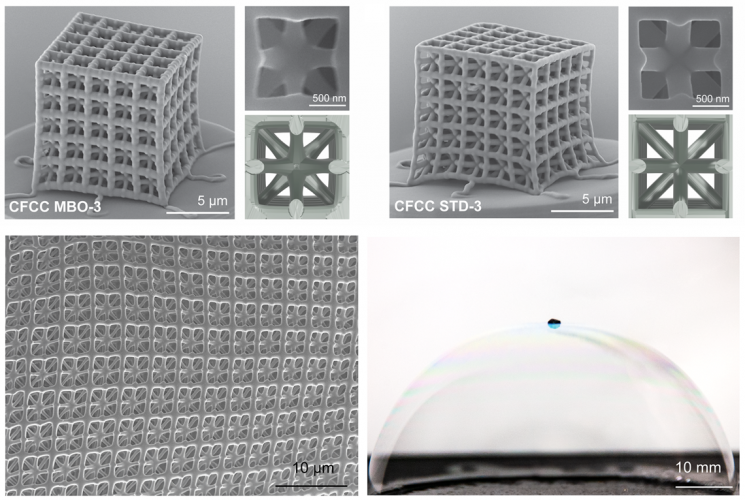

FESEM (Field Emission Scanning Electron Microscope) image of the fabricated nano lattice structure and the structure placed on the bubble. Provided by KAIST

FESEM (Field Emission Scanning Electron Microscope) image of the fabricated nano lattice structure and the structure placed on the bubble. Provided by KAIST

In this study, the research team optimized the beam shape of the lattice structure to maximize stiffness and strength while maintaining lightweight characteristics.

In particular, they performed optimal design considering tensile and shear stiffness improvement and weight reduction simultaneously by utilizing a "Multi-objective Bayesian Optimization" algorithm, which finds the best solution by considering multiple objectives at once. This demonstrated that the optimal lattice structure can be predicted and designed with significantly fewer data points (about 400) compared to conventional methods.

Additionally, to maximize the effect of improved mechanical properties as size decreases at the nanoscale, the team implemented an ultra-lightweight, high-strength, and high-stiffness nano lattice structure using pyrolytic carbon material, a carbon substance obtained by decomposing organic matter at high temperatures.

Using two-photon polymerization (2PP) technology, where polymerization occurs only when two photons of a specific wavelength are absorbed simultaneously by a laser beam, they achieved strength comparable to steel while maintaining the lightweight nature of Styrofoam. Furthermore, by employing multi-focus 2PP technology, they demonstrated the capability to fabricate millimeter-scale structures while maintaining nanoscale precision.

Professor Seunghwa Yoo expressed, "This technology, which combines data-driven optimal design and precision 3D printing, not only meets the lightweight demand in aerospace and automotive industries but also opens up possibilities for various industrial applications through customized design."

The research was led by Dr. Peter Serles and Dr. Jinwook Yeo of KAIST as co-first authors, with Professor Seunghwa Yoo and Professor Tobin Filleter serving as corresponding authors.

The research results were published on the 23rd of last month in the prestigious international journal Advanced Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.