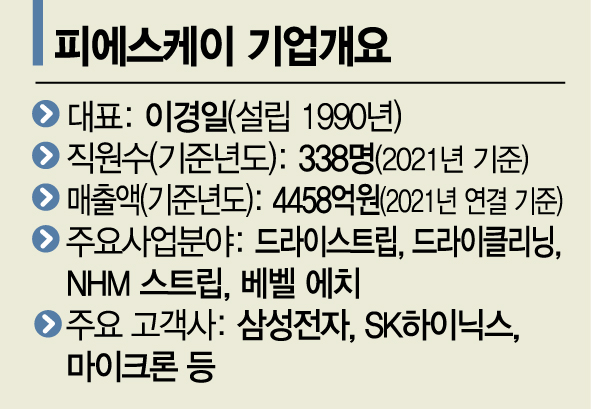

PSK, the World's No.1 Semiconductor Dry Strip Equipment Company

SEMI Selects PSK as the Only Domestic 'Leader' in the US Semiconductor Supply Chain Report

First Domestic Localization of Bevel Etch, Previously Monopolized by US Lam Research

Invested a Total of 82.5 Billion KRW to Build Pangyo R&D Center, to be Completed in 2024

[Asia Economy Reporter Kwak Min-jae] Bevel Etch is equipment that leaves the rounded edge part of a semiconductor wafer (substrate) intact using chemical agents while removing the rest. The wafer edge is difficult to control physically and chemically, affecting semiconductor yield (the ratio of defect-free qualified products), and this equipment helps improve semiconductor yield. PSK, a semiconductor front-end equipment company, recently succeeded in domestic production of this equipment, which was monopolized by the global American equipment company Lam Research.

PSK CEO Lee Kyung-il met with reporters at the company's headquarters in Hwaseong, Gyeonggi Province, on the 6th and said, "In the past, bevel etch was not a key piece of equipment in semiconductor processes, but as semiconductor integration increased and the price per chip rose, its importance has grown along with yield. This year, initial sales occurred in SK Hynix's mass production division, and since last month, we have succeeded in supplying this equipment to Samsung Electronics," he said.

Recognized as the World ‘Leader’ in Strip Equipment Field

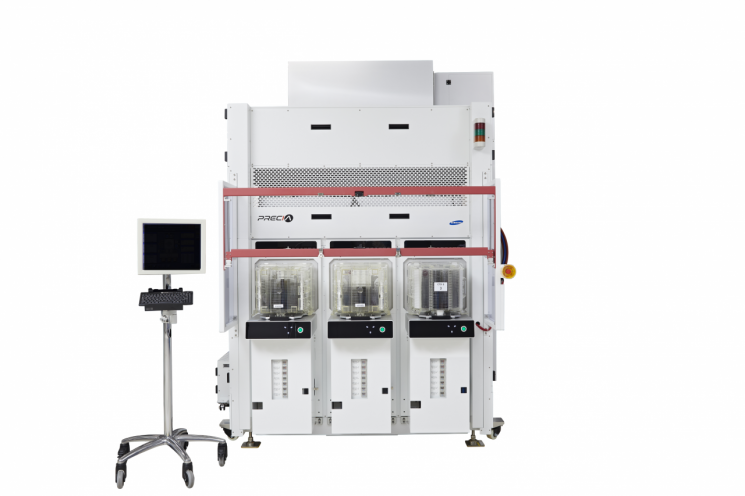

PSK is the world's number one (42% market share) company in dry strip (photoresist remover) equipment. It removes photoresist (PR) residues left after the photolithography process, which draws circuit patterns to create the desired semiconductor on the wafer. In particular, PSK has technology that minimizes plasma-induced damage to stably remove photoresist. Recognized for this technology, PSK was named the world ‘leader’ in the strip equipment field in last year's Semiconductor Equipment and Materials International (SEMI) ‘U.S. Semiconductor Supply Chain Report’ analysis. PSK is the only Korean company selected as a ‘leader’ in any equipment field.

PSK counts global semiconductor companies such as Samsung Electronics, SK Hynix, and Micron among its clients. CEO Lee said, "We have about 30 bases in six countries including the U.S., Taiwan, China, Ireland, Japan, and Singapore," adding, "Even during the cooldown period when domestic semiconductor investment was sluggish, PSK's competitiveness allowed us to receive orders and deliver equipment to overseas global companies."

Developing new equipment every 2-3 years is also a core strategy. Based on PSK's strength in plasma technology, it has successively developed new equipment such as dry cleaning and NHM strip equipment. Through this, sales have continuously grown from 154.6 billion KRW in 2019 to 265.7 billion KRW in 2020 and 445.8 billion KRW in 2021. PSK is also strong in the non-memory semiconductor field, which is rare among domestic equipment companies. While 70-80% of past sales were in memory equipment, the share of sales in this field has greatly increased since two years ago when PSK supplied dry strip equipment applied to system semiconductors to a large North American semiconductor company. PSK is closely cooperating with this company's European investment, expecting further growth in non-memory field sales.

Building an R&D Center in Pangyo to Target the 'Etch Market'

PSK views the ‘etch market’ as a future new business. The etch process removes underlying films without photoresist attached on the surface, leaving only the necessary patterns. Starting with the recently domestically produced bevel etch equipment, PSK is strengthening research and development to develop etch equipment used in main processes. Etch equipment has the second-largest market size among semiconductor equipment after photolithography equipment.

To this end, PSK is constructing a 15-story integrated R&D campus in Pangyo Second Technovalley. Together with its parent company PSK Holdings, it is investing a total of 82.5 billion KRW, with completion scheduled for 2024. CEO Lee said, "Starting from the Pangyo R&D center, we plan to secure excellent talent and continuously develop new equipment ranging from film removal technology using existing plasma technology to film deposition processes," adding, "Through new business entry, we aim to achieve sales of 1 trillion KRW by 2025."

CEO Lee, a professional manager, worked as a senior manager for seven years at Applied Materials, a global American equipment company, and as CTO for 12 years at Matson Technology, a dry strip specialist company, before joining PSK in 2016.

The company recently decided to cancel treasury shares worth 10.4 billion KRW, also engaging in shareholder-friendly management emphasized by the founder. PSK originated from Kumyoung Trading, founded in 1986 by Chairman Park Kyung-soo. Chairman Park operated as an agent for the Japanese semiconductor company PSC and, with a dream of domestic production, established PSK Tech in 1990 through a joint venture with Japan's Plasma System and Nippon Sanso. Chairman Park succeeded in domestic production of dry strip equipment for the first time in Korea in 1997 and applied the world's first 300mm dry strip equipment to mass production lines in 2001.

Gyeonggi Hwaseong = Reporter Kwak Min-jae

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.