Interview with Ryu Sang-hoon, CEO of Eco R&S

Eco-friendly recycling of waste batteries using dry smelting method

Carbon dioxide consumption... Holds patented core technology

"I believe there is no company that can match Eco R&S's innovative eco-friendly technology in the electric vehicle (EV) waste battery recycling industry." Ryu Sang-hoon, CEO of Eco R&S, spoke with confidence. EV waste batteries are composed of lithium, nickel, cobalt, and other materials, and if discarded as is, they cause soil pollution. Having majored in chemistry and worked in the logistics industry, CEO Ryu founded Eco R&S to solve this problem and developed technology to eco-friendly recover valuable metals usable from waste batteries.

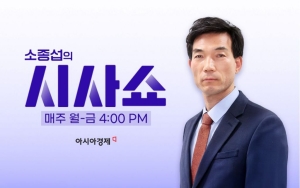

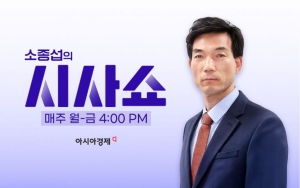

![[Climate Tech Series⑩] Electric Vehicle Waste Batteries Soon to Flood the Market... Eco R&S's 'Eco-Friendly Recycling'](https://cphoto.asiae.co.kr/listimglink/1/2024052915404088964_1716964839.jpg) Eco RnS (RnS) CEO Ryu Sang-hoon is being interviewed by Asia Economy at the office of an investment firm in Gangnam-gu, Seoul. Photo by Heo Young-han younghan@

Eco RnS (RnS) CEO Ryu Sang-hoon is being interviewed by Asia Economy at the office of an investment firm in Gangnam-gu, Seoul. Photo by Heo Young-han younghan@

On the 19th, CEO Ryu said, "Turning discarded waste into recyclable resources is socially necessary, but since it is not well implemented in our country, I started the business myself." He added, "Especially, many EV waste batteries are discarded while still having about 70% of their capacity left. I thought it was a waste to use scarce resources like lithium just once and throw them away, so I sought recycling solutions." Depending on the manufacturer, model, raw materials, and size, a single waste battery typically contains 7-9% lithium.

Eco R&S conducts the entire EV waste battery recycling process in an eco-friendly manner based on patented technology that consumes carbon dioxide. First, through a pretreatment process, unnecessary parts of the waste battery are removed, producing a black powder. From this point, the recycling process begins. Eco R&S uses a dry smelting method by placing carbon dioxide and the black powder into an electric furnace to produce lithium carbonate. Since about 70% of the amount of black powder used in the process requires carbon dioxide, the more material recycled, the more carbon dioxide can be eliminated. Also, the water generated during the recycling process is not discharged as wastewater but recovered and reused in the process, preventing additional pollution.

In the resource extraction industry, metals are generally extracted through hydrometallurgy. The hydrometallurgical process, which uses sulfuric acid solution to recover metals, produces greenhouse gases and wastewater, causing secondary pollution. Therefore, Eco R&S did not follow the conventional method and secured core technology after researching an eco-friendly dry smelting method. CEO Ryu said, "In Korea, only companies like Korea Zinc and Young Poong perform dry smelting, but I understand it takes more time to commercialize. Eco R&S is the only company using gaseous carbon dioxide in this way."

Based on this technological capability, Eco R&S has gained advantages overseas, including Europe. According to the European Union (EU) 'Battery Act' enacted this year, batteries produced and sold within Europe must disclose the total amount of carbon dioxide emissions (carbon footprint) generated during the manufacturing process. CEO Ryu said, "Companies making batteries like Samsung SDI and LG Energy Solution must use recycled materials and disclose total carbon dioxide emissions to sell in Europe. Therefore, Eco R&S, which has strengths in carbon dioxide emission rights, is bound to grow further."

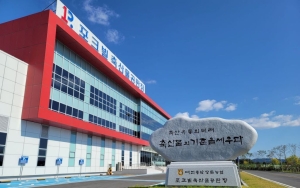

![[Climate Tech Series⑩] Electric Vehicle Waste Batteries Soon to Flood the Market... Eco R&S's 'Eco-Friendly Recycling'](https://cphoto.asiae.co.kr/listimglink/1/2024061810572520107_1718675845.jpeg) At the Eco R&S laboratory located on Pukyong National University Yongdang Campus, the recycling process of waste batteries using an electric furnace is underway.

At the Eco R&S laboratory located on Pukyong National University Yongdang Campus, the recycling process of waste batteries using an electric furnace is underway. [Photo by Eco R&S]

Founded in 2020, Eco R&S has undergone four years of research and is preparing to establish a factory. Experiments to recover nickel and cobalt along with lithium carbonate from waste batteries have also been completed. CEO Ryu said, "Based on data accumulated through pilot equipment, we are almost ready to achieve results," adding, "We expect the full-scale collection of waste batteries in Korea to begin within two years." He also added, "Once the dry smelting plant is built, it is expected to process more than 1,000 tons of black powder per month." Currently, the amount of black powder that can be processed monthly is 300 kg.

CEO Ryu dreams of building a company that can conduct comprehensive recycling businesses beyond just waste batteries. He said, "I want to expand the business into plastic recycling and become a foundation for an eco-friendly society."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.