Possesses Magnetite Mines

Stable Supply of Renewable Energy

Forward Base for Overseas Hydrogen-Reduced Iron

POSCO is moving forward with the acquisition of the Whyalla steelworks in Australia. This move is seen as a strategic step to achieve self-sufficiency in steelmaking raw materials and to establish a next-generation steel production system. Analysts note that the Whyalla steelworks area, which has access to magnetite mines and abundant renewable energy, could serve as a forward base for the production and export of hydrogen-reduced iron in the long term.

According to industry sources on August 5, POSCO has formed a consortium with Australia's BlueScope, Japan's Nippon Steel, and India's JSW Group, and has submitted a non-binding preliminary letter of intent to the South Australian state government regarding the acquisition of assets of the Whyalla steelworks. The consortium's selection as the final acquirer will be determined after due diligence and further review by the South Australian government.

The Whyalla steelworks, which began operations in 1941, is an aging blast furnace-based facility with an annual bar steel production capacity of approximately 1.2 million tons. POSCO's motivation for pursuing this acquisition lies in its strategy to establish a low-carbon steel production system. The Whyalla site has a magnetite mine, and South Australia is a region that can stably supply renewable energy based on abundant solar and wind power.

POSCO is considering using iron ore produced in this region as a forward base, processing it into direct reduced iron (DRI) or hot briquetted iron (HBI) for supply to hydrogen-based steelworks in Korea, India, and other overseas locations. Although POSCO has not yet officially announced local production of DRI and HBI, analysts believe that, amid the global shift toward hydrogen-based steel production, this site could become a strategic hub for securing low-carbon raw materials and responding to the Carbon Border Adjustment Mechanism (CBAM).

A POSCO official said, "The acquisition of the Whyalla steelworks is not an immediate decision to produce DRI and HBI locally, but we are approaching it with the possibility of doing so in the mid- to long-term," adding, "Separately from the acquisition, we plan to review various models for utilizing hydrogen based on renewable energy and for processing iron ore in the future."

DRI and HBI are produced by removing oxygen from iron ore to make iron, using hydrogen or natural gas instead of coal. Iron ore is an iron oxide mineral composed of iron (Fe) and oxygen (O), and to use it in steelmaking, the oxygen must be removed to reduce it to pure iron. The traditional blast furnace method burns coal in this reduction process, emitting large amounts of carbon dioxide. In contrast, DRI uses hydrogen or natural gas, which can drastically reduce greenhouse gas emissions, making it a "low-carbon reduction raw material." HBI is a form of DRI compressed at high temperatures, which is less prone to oxidation and easier to transport over long distances.

Currently, POSCO imports HBI from Australia for use. The company believes that if it can produce HBI locally through the acquisition of the Whyalla steelworks, it will be able to achieve both economic efficiency and stability by reducing import and logistics costs. It also expects this to strengthen its self-sufficiency in low-carbon raw materials within the global supply chain.

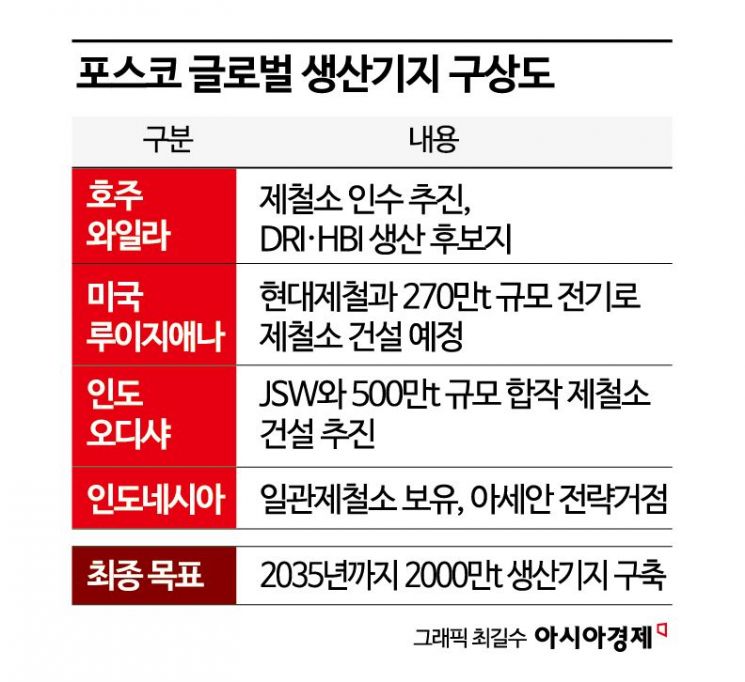

This acquisition is also expected to accelerate POSCO's efforts to establish global production bases in countries such as the United States and India. POSCO, together with Hyundai Steel, is working to build an electric arc furnace steel mill in Louisiana, USA, with an annual capacity of 2.7 million tons. In India, POSCO is partnering with JSW Group on preliminary work for a joint steel mill with an annual capacity of 5 million tons. In addition, including overseas bases such as Indonesia, POSCO aims to establish a global steel production system with a capacity of 20 million tons by 2035.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.