From Two Shifts to Three Under the 52-Hour Workweek... "Labor Costs Up 30%"

Reduced Skilled Worker Hours Lead to Quality and Productivity Decline... Root Companies Face Wave of Closures

Labor Shortage Causes Tight Deadlines... High Fees Paid for Headhunters

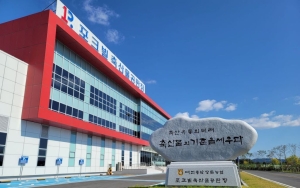

[Asia Economy Reporters Kim Heeyoon and Lee Junhyung] The construction site of Shin-Kori Nuclear Power Plant Units 5 and 6 in Ulju-gun, Ulsan Metropolitan City, recently experienced work stoppages and construction disruptions. This was due to 20 construction subcontractors declaring a strike, driven to the brink of closure by the labor cost burden following the implementation of the 52-hour workweek system. Kim Seonggi, site manager of subcontractor Da I&C, said, "The daily working hours were reduced from 10 to 8 hours, but since the workers' wages, based on a daily wage concept, were maintained, the labor cost burden increased by nearly 30%. With the construction period extended by 15 months, labor costs alone amounted to 5 billion KRW, and if this cost is not supported by the primary contractor or Korea Hydro & Nuclear Power, companies like ours will inevitably go bankrupt."

Small and medium-sized enterprises (SMEs) have been caught in the crossfire of the current government's pro-labor policies, such as the 52-hour workweek and minimum wage increases. Root companies, which form the foundation of manufacturing competitiveness, are facing the threat of collapse. This has raised concerns that the competitiveness of SMEs could deteriorate to its worst level.

SMEs’ Cost Burden Reaches ‘Limit’

The 52-hour workweek system has directly increased the cost burden on SMEs. From July this year, the 52-hour workweek was expanded to workplaces with 5 to fewer than 50 employees. Heat treatment company A, located in Miryang, Gyeongnam, increased its production workforce by 40 to operate the factory in three shifts. Until recently, the company operated the factory in two shifts with 40 workers during the day and 40 at night. The CEO of company A said, "Because we couldn't hire enough employees, about 30 daily workers from staffing agencies are used every day to keep the factory running. Labor costs have increased significantly, but since many are unskilled workers, both quality and productivity have declined."

As the cost burden has increased daily due to the implementation of the 52-hour workweek, many small businesses in the root industry are closing down. According to the Gyeongin Casting Industrial Complex Business Cooperative, in the Gyeongin Casting Complex located in Seo-gu, Incheon, 3 out of 15 casting companies have closed in the past year. All three were long-established companies founded in the 1960s and 1970s. One company went bankrupt, and the other two chose voluntary closure. The financial conditions of the remaining 12 companies are also reported to be poor. This is why there are industry voices saying that the root industry is being shaken to its core.

‘Double Hardship’ from Rising Labor Costs and Labor Shortages

Labor shortages are another problem. The situation is especially severe for manufacturing-based SMEs. To comply with the 52-hour workweek, companies need to increase staff, but many are barely meeting delivery deadlines due to chronic labor shortages, according to industry sources. Additionally, root companies, which are seriously aging, are helpless against the Serious Accidents Punishment Act. A representative from the Gyeongin Casting Industrial Complex Business Cooperative said, "Most production workers in root companies are elderly, which increases the risk of accidents."

Last month, the Korea Federation of SMEs surveyed 414 companies with fewer than 300 employees about the implementation of the 52-hour workweek, and 54.1% responded that they are facing difficulties due to the system. Labor shortages caused by the 52-hour workweek were particularly prominent in manufacturing companies. One out of two manufacturers complained about the heavy labor cost burden from additional hiring. The shortage of workers due to the 52-hour workweek combined with the minimum wage increase is causing a double hardship.

Cases of companies resorting to headhunting agencies despite high fees have also increased. Robot parts company B, located in Gimpo, Gyeonggi Province, recently commissioned a headhunting firm to recruit 8 R&D personnel within the year. This was because the desired candidates rarely applied through job platforms. The CEO of company B said, "When using a headhunting company, we have to pay a fee of 15-25% of the engineer's annual salary."

Lee Taehee, head of the Smart Job Division at the Korea Federation of SMEs, said, "Many SMEs are struggling with the 52-hour workweek due to cost burdens, recruitment difficulties, and flexible work systems that do not fit the field. Workers are also taking on second jobs to compensate for reduced overtime pay caused by the 52-hour workweek. Institutional improvements such as introducing an extended work system allowing more work hours if both labor and management agree, and improving the special extended work permit system, are urgently needed."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![[Countries Where Running SMEs Is Difficult] ③ SMEs Trapped by the 52-Hour Workweek and Minimum Wage Snare](https://cphoto.asiae.co.kr/listimglink/1/2021042108521290493_1618962733.jpg)

![[Countries Where Running SMEs Is Difficult] ③ SMEs Trapped by the 52-Hour Workweek and Minimum Wage Snare](https://cphoto.asiae.co.kr/listimglink/1/2021112511202935977_1637806829.jpg)

![[Countries Where Running SMEs Is Difficult] ③ SMEs Trapped by the 52-Hour Workweek and Minimum Wage Snare](https://cphoto.asiae.co.kr/listimglink/1/2021112511124835943_1637806369.jpg)